A self-learning-based lifting control system and its anti-pinch method

A lifting control and self-learning technology, which is applied to tables with variable table heights, household utensils, furniture parts, etc., can solve problems such as collisions of moving parts, potential safety hazards, and tilting of moving parts, so as to improve the safety performance of use and reduce production costs. Consistency requirements, the effect of eliminating the consistency deviation of moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

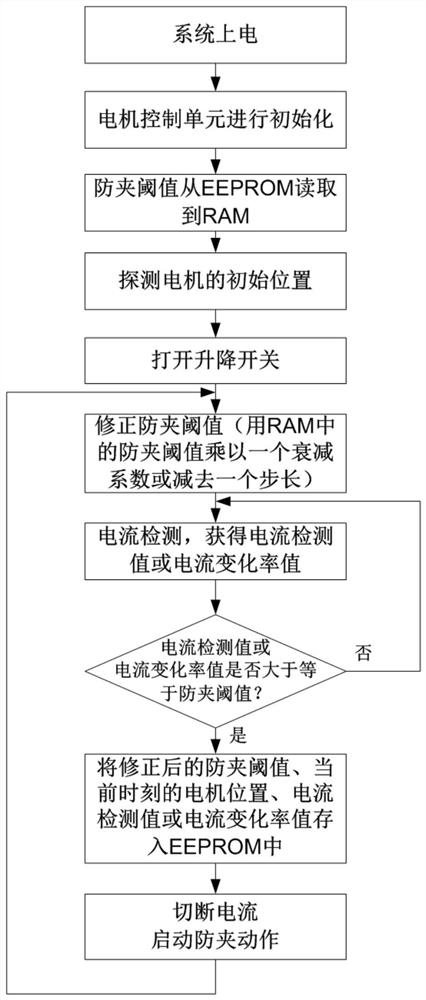

[0082] The motor control unit can identify the anti-pinch state based on information such as steady-state current, actuating stroke, motor position, and anti-pinch threshold. The motor control unit records the current detection value or the current change rate value, the motor position, and the anti-pinch threshold value when the anti-pinch occurs, and stores it in the storage part of the motor control unit, for example, into the EEPROM, so that even if the power is turned on again, it will not be Lost recorded data. However, before the next anti-pinch occurs, it is necessary to reduce the anti-pinch threshold of the next anti-pinch judgment condition correspondingly by a certain proportion or in equal steps. easier to trigger.

[0083] figure 1 It is a schematic flowchart of an anti-pinch method based on a self-learning lifting control system.

[0084] like figure 1 As shown, the anti-pinch self-learning method includes the following steps:

[0085] Step A1: The system i...

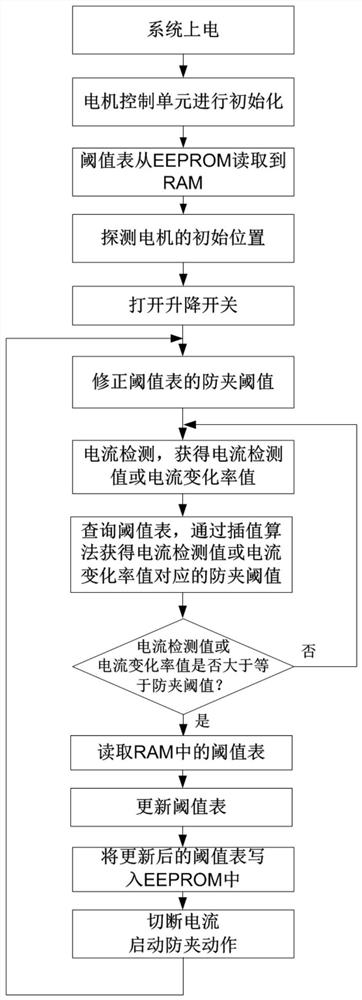

Embodiment 2

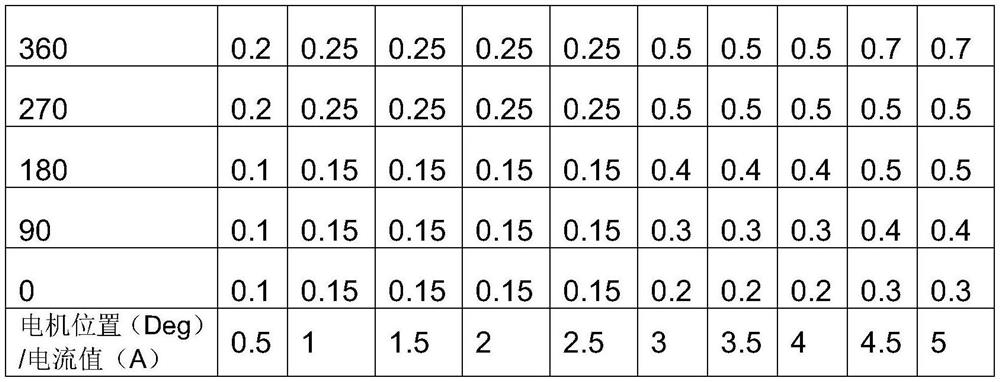

[0101] The EEPROM of the motor control unit can be preset with a threshold table, which can be divided into blocks according to different values according to main characteristic information such as current or current change rate, motor position, and each block stores different learned values. Anti-pinch threshold. In practical applications, the interpolation algorithm can be used to obtain different anti-pinch thresholds under different current detection values at different positions, which can be used for anti-pinch judgment.

[0102] Table 1 gives an example of a threshold table. As shown in Table 1, the table stores the anti-pinch thresholds corresponding to different current values under different motor positions. At this time, the motor power supply voltage is 12V, the no-load speed is 300+ / -10% RPM, and the rated load is 1.2 Nm.

[0103] Table 1, Threshold Table

[0104]

[0105] The motor control unit can obtain the current value and motor position detected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com