Automatic cocoon harvesting assembly line used in industrial silkworm breeding operation

A mid-operation, factory-like technology, applied in animal husbandry, etc., can solve the problems of low silkworm cocoon output, slow operation, and small scale, and achieve the effects of ensuring the quality of cocoon picking, widening the sweeping range, and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

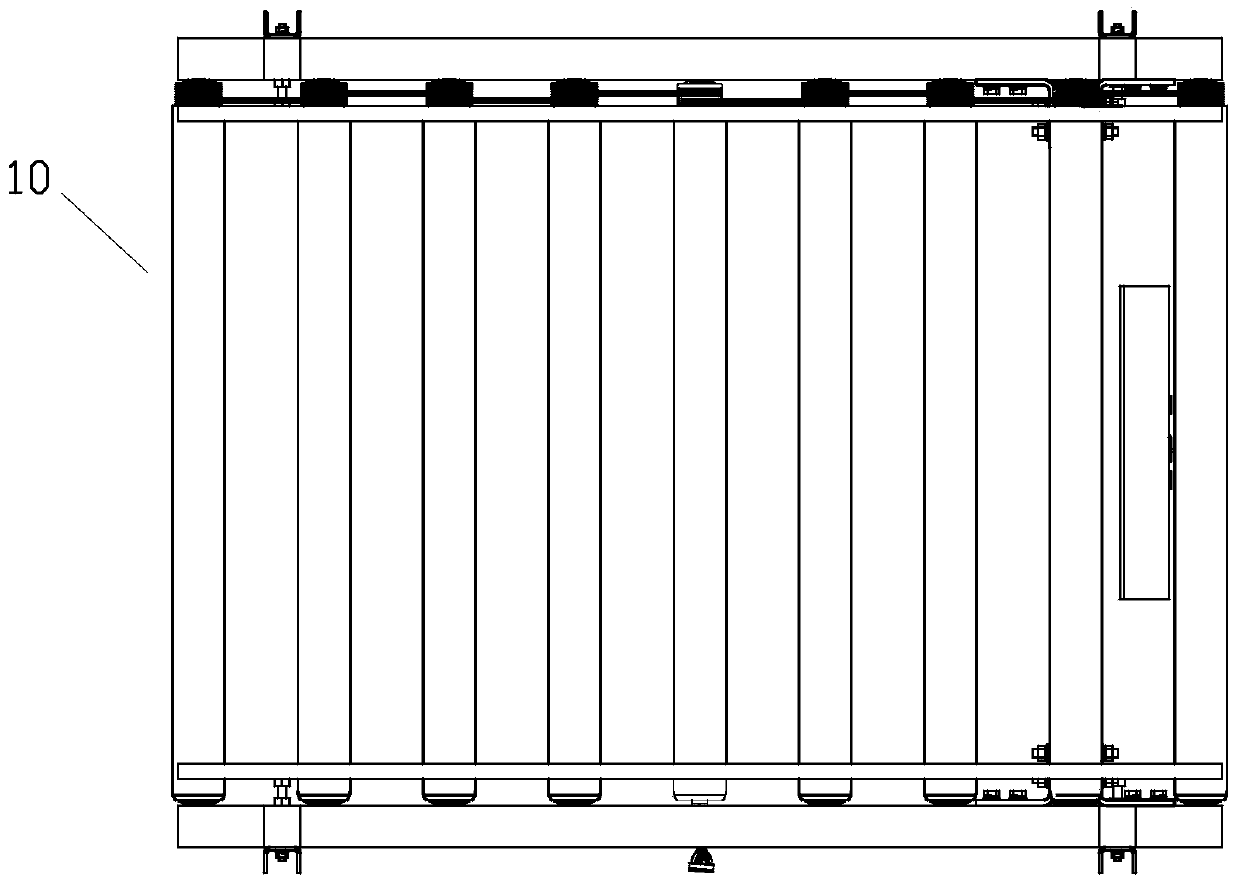

[0045] like Figure 1 to Figure 19 As shown in the figure, the automatic cocoon picking line in the factory silkworm breeding operation is composed of the feeding conveyor line, the breeding frame dismantling machine 3, the frame bottom cocoon picking machine 4, the sorting line and the cocoon picking machine 9. , the feeding conveyor line is connected to the breeding frame unpacking machine 3, the breeding frame unpacking machine 3 is connected to the frame bottom cocoon picking machine 4, the frame bottom cocoon picking machine 4 is connected to the sorting line, and the sorting line is connected to the cocoon picking machine 9. The cocoons of the cocoon box and the cocoon cage carry out a full range of cocoon picking.

[0046] 1. Feeding into the conveyor line:

[0047] The feeding conveying line includes a transverse rail conveying line 1 and a longitudinal rail conveying line 2. Both the transverse rail conveying line 1 and the longitudinal rail conveying line 2 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com