Formation method of lithium iron phosphate battery with square aluminum shell for energy storage

A technology for aluminum shell lithium iron phosphate and batteries, which is applied in the field of formation of lithium iron phosphate batteries, and can solve problems such as the mismatch between formation process and usage system, and battery performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

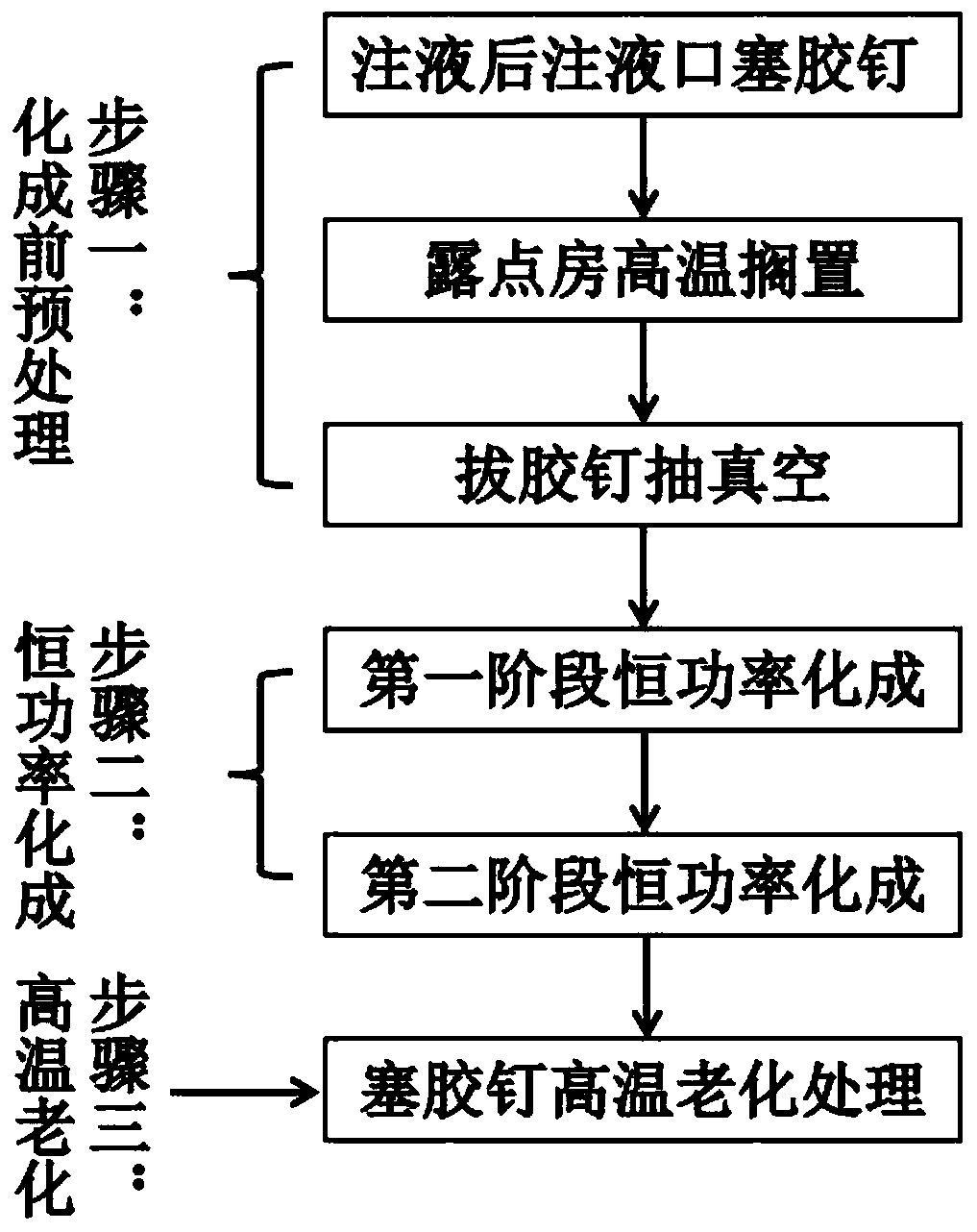

[0025] A method for forming a square aluminum shell lithium iron phosphate battery for energy storage of the present invention comprises the following steps:

[0026] Step 1: Pretreatment before chemical synthesis

[0027] First, measure the moisture content of the 27175200 square aluminum case lithium iron phosphate battery roll core, which is 400ppm; the 96Ah square aluminum case lithium iron phosphate battery (the positive pole is Guoxuan lithium iron phosphate material, and the negative pole is Shanghai Shanshan FSN Artificial graphite material, the diaphragm is Jinli 12+4 single-sided ceramic diaphragm, and the electrolyte is Guangzhou Tianci EGX special electrolyte containing negative electrode film-forming additives) for plugging treatment; the lithium iron phosphate battery after the plugging nail is placed in Put it aside for 12 hours at 45°C in a high-temperature room with a dew point of -45°C, so that the electrolyte can fully infiltrate the positive and negative el...

Embodiment 2

[0034] A method for forming a square aluminum shell lithium iron phosphate battery for energy storage of the present invention comprises the following steps:

[0035] Step 1: Pretreatment before chemical synthesis

[0036]First, measure the moisture content of the 27175200 square aluminum case lithium iron phosphate battery roll core pole piece, which is 380ppm; the 105Ah square aluminum case lithium iron phosphate battery (the positive electrode is Guoxuan lithium iron phosphate material, and the negative electrode is Shanghai Shanshan EP -15 artificial graphite material, the diaphragm is Jinli 12+4 single-sided ceramic diaphragm, and the electrolyte is Guangzhou Tianci EGX special electrolyte containing negative electrode film-forming additives) for plugging nail treatment; the lithium iron phosphate battery after plugging the rubber nail Put it in a high-temperature room with a dew point of -35°C at 60°C for 24 hours, so that the electrolyte can fully infiltrate the positiv...

Embodiment 3

[0042] A method for forming a square aluminum shell lithium iron phosphate battery for energy storage of the present invention comprises the following steps:

[0043] Step 1: Pretreatment before chemical synthesis

[0044] First, measure the moisture content of the 54175200 square aluminum case lithium iron phosphate battery roll core pole piece, which is 420ppm; the 230Ah square aluminum case lithium iron phosphate battery (the positive pole is Guoxuan lithium iron phosphate material, the negative pole is Shanghai Shanshan EP -15 artificial graphite material, the diaphragm is Jinli 12+4 single-sided ceramic diaphragm, and the electrolyte is Guangzhou Tianci EGX special electrolyte containing negative electrode film-forming additives) for plugging nail treatment; the lithium iron phosphate battery after plugging the rubber nail Put it in a high-temperature room with a dew point of -55°C at 40°C for 36 hours, so that the electrolyte can fully infiltrate the positive and negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com