Quick closing mechanism

A fast, DC motor technology, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of complex installation, complex structure, low speed of AC motor, etc., and achieve the effect of saving space, reducing height, and reducing manual mechanism settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

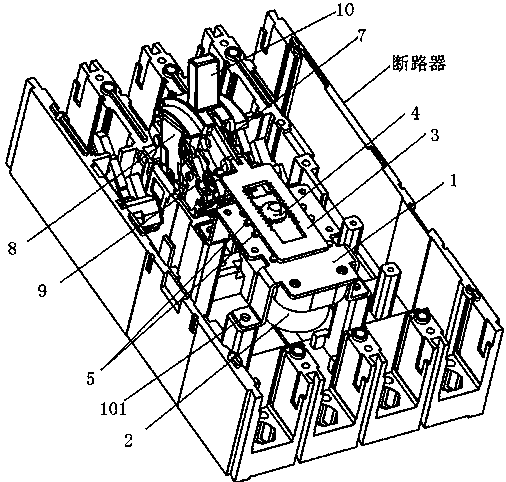

[0037] The invention relates to the field of circuit breakers. It is a mechanism for fast closing on the circuit breaker. It is used based on a molded case circuit breaker and includes a power source for electric closing, a DC motor 2; it is connected with the circuit breaker and used for fixing the DC The motor fixing plate 1 of the motor 2; the inner double-tooth rack 3 that is slidably connected to the upper surface of the motor fixing plate 1 and whose front end is rotatably connected to the lever bracket 8 of the circuit breaker main mechanism; The incomplete gear 4 engaged with the racks on both sides is fixedly connected with the output shaft of the DC motor 2 . In this embodiment, a plurality of through holes 101 are opened around the motor fixing plate 1, and are fixed on the circuit breaker by screws, see the attached figure 1 . Inner double-toothed rack 3 is elongated, hollow in the middle, and the toothed rack of its both sides is arranged relatively, and incomple...

Embodiment approach 2

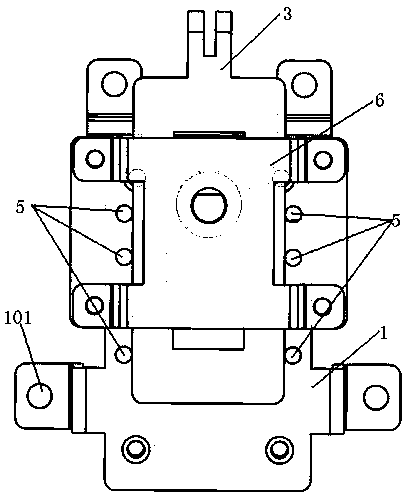

[0041] This embodiment is a further improvement on Embodiment 1. The improvement is as follows: set several stop protrusions 5 on the motor fixing plate 1, the stop protrusions 5 are located on both sides of the inner double-teeth rack 3, and the inner double teeth The rack 3 is limited to a vertical position, and it can only slide forward and backward, but not left and right. A cover plate 6 is arranged above the inner double-toothed rack 3, and the two sides of the cover plate 6 are fixed on the motor fixing plate 1 by screws, so that the inner double-toothed rack 3 is limited up and down and will not fall.

[0042] DC motor 2 output shafts pass cover plate 6 and have a stopper at the end of output shaft, output shaft is just rotatably connected to cover plate 6 like this, and incomplete gear 4 rotates with output shaft rotation.

Embodiment approach 3

[0044]This embodiment is a further improvement on Embodiment 1. The improvement plan is: the motor fixing plate 1 is set in an arched shape, the DC motor 2 is fixed under the arched motor fixing plate 1, and the output shaft of the DC motor 2 passes through the motor fixing plate 1 Connected with the incomplete gear 4, the motor fixing plate is arched so that the DC motor 2 can be placed under the arch, saving space and greatly reducing the height of the product.

[0045] working principle:

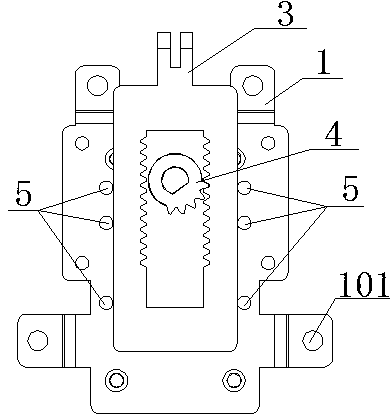

[0046] 1. Such as image 3 As shown, when the circuit breaker is in the opening state, the tooth mouth of the incomplete gear 4 is set upward at this time, and the several tooth mouths set on the incomplete gear 4 do not mesh with the tooth mouths on both sides of the inner double-toothed rack 3, At this time, the switch can be closed manually.

[0047] 2. Such as Figure 4 As shown, when the circuit breaker needs to be buckled again, the DC motor 2 is started, and the incomplete gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com