Real-time loading, heating and leaching test device in CT scanning process

A CT scanning and test device technology, applied in measurement devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems that rock mechanics research cannot meet, and can not realize real-time loading, etc., to avoid large attenuation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

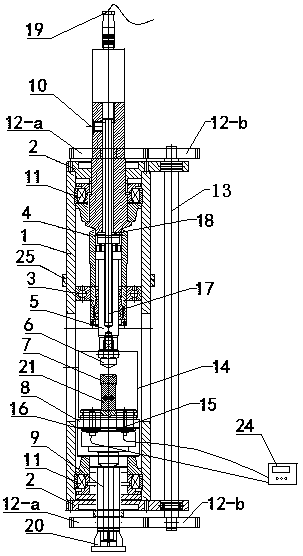

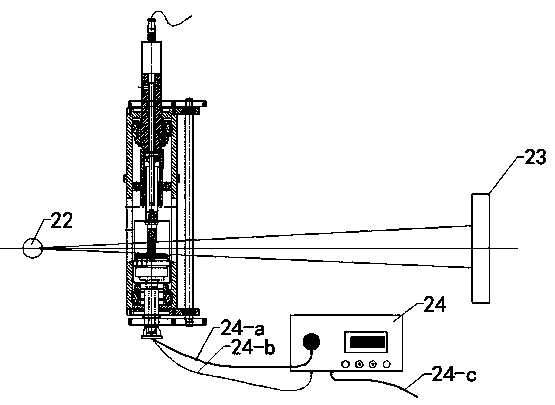

[0017] The real-time loading heating and leaching test device in the CT scanning process of the present invention includes: a fixed frame, pressure loading, mechanical rotation, liquid immersion and displacement sensors;

[0018] Wherein, the fixed frame part includes a cylindrical bracket 1, an end cover 2, an upper fixing part 3 and a supporter fixing screw hole 25; The two ends of the cylindrical support 1 are closed; two rectangular windows are set in the middle of the cylindrical support 1 to realize the passage of rays and the disassembly and assembly of the test pieces in the tube; the upper fixing part 3 is ring-shaped and fixedly arranged on the Inside the cylindrical support 1, the supporter fixing screw hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com