A method and device for controlling the movement of a synchronizer

A technology of synchronizer and synchronization point, which is applied in the direction of transmission control, components with teeth, belt/chain/gear, etc. Avoid damage, ensure comfort, and ensure the effect of shifting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

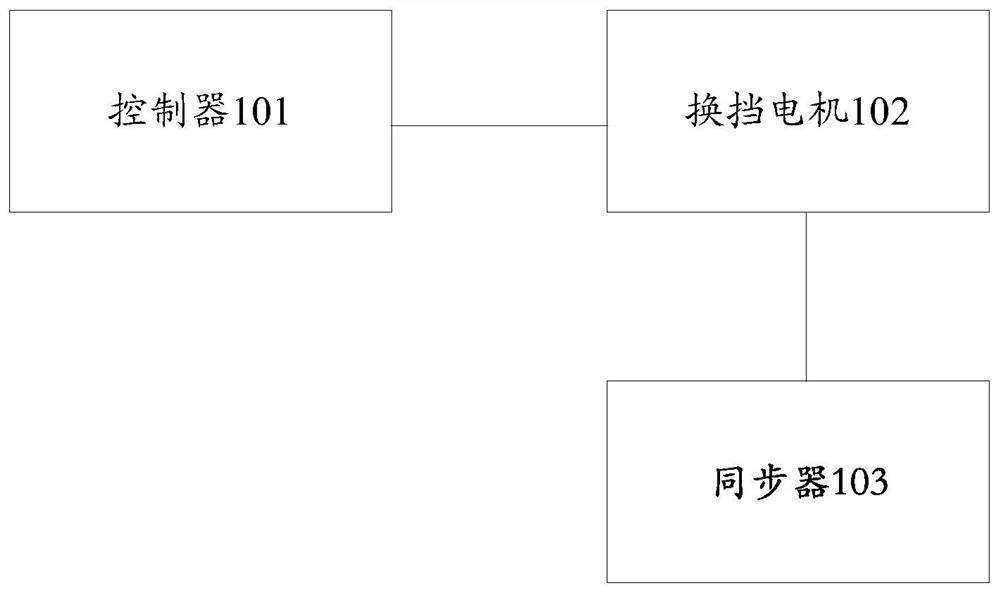

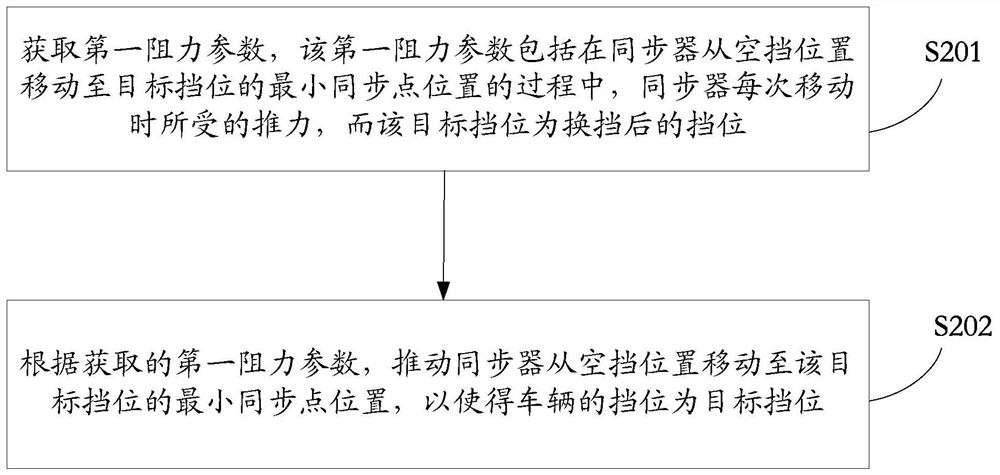

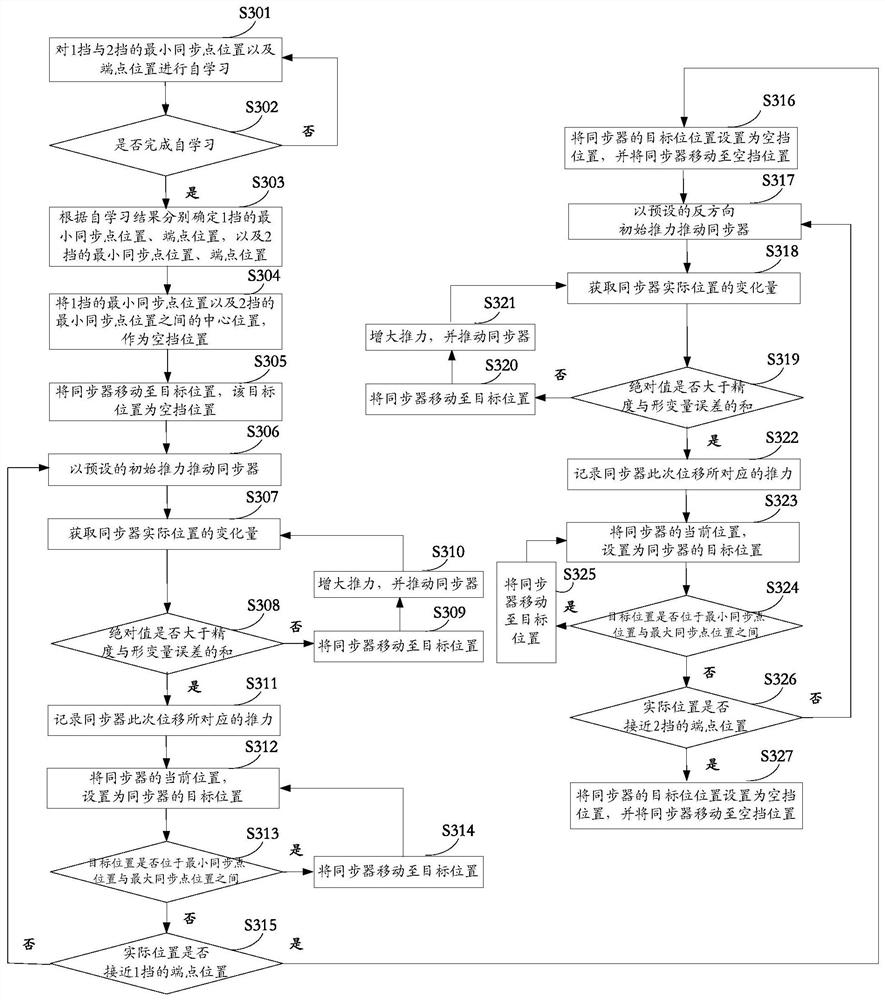

[0043] The inventor found through research that due to the unavoidable errors in the transmission process such as processing, manufacturing, and assembly, there are certain differences in the shift resistance characteristics of the various gearboxes that leave the factory. During the process, the moving resistance of the synchronizer in each gearbox is not the same, and there is a large difference in the shift resistance characteristics of each gearbox. Therefore, if the shift motor pushes the synchronizer to move and complete the shift smoothly, For the synchronizer in different gearboxes, the shift motor needs different thrusts to push the synchronizer to move.

[0044] However, at present, for the synchronizers in different gearboxes, the shift motors push the synchronizers to move with a fixed force. If the thrust pushing the synchronizer is small, the moving displacement of the synchronizer will be short, which may make the synchronizer unable to move into the gear normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com