Method of producing pneumatic tire and housing holder of bead member

A technology for pneumatic tires and manufacturing methods, applied to tire parts, vehicle parts, tires, etc., which can solve the problems of unrecorded bead parts manufacturing processes, etc., and achieve the effect of suppressing poor molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

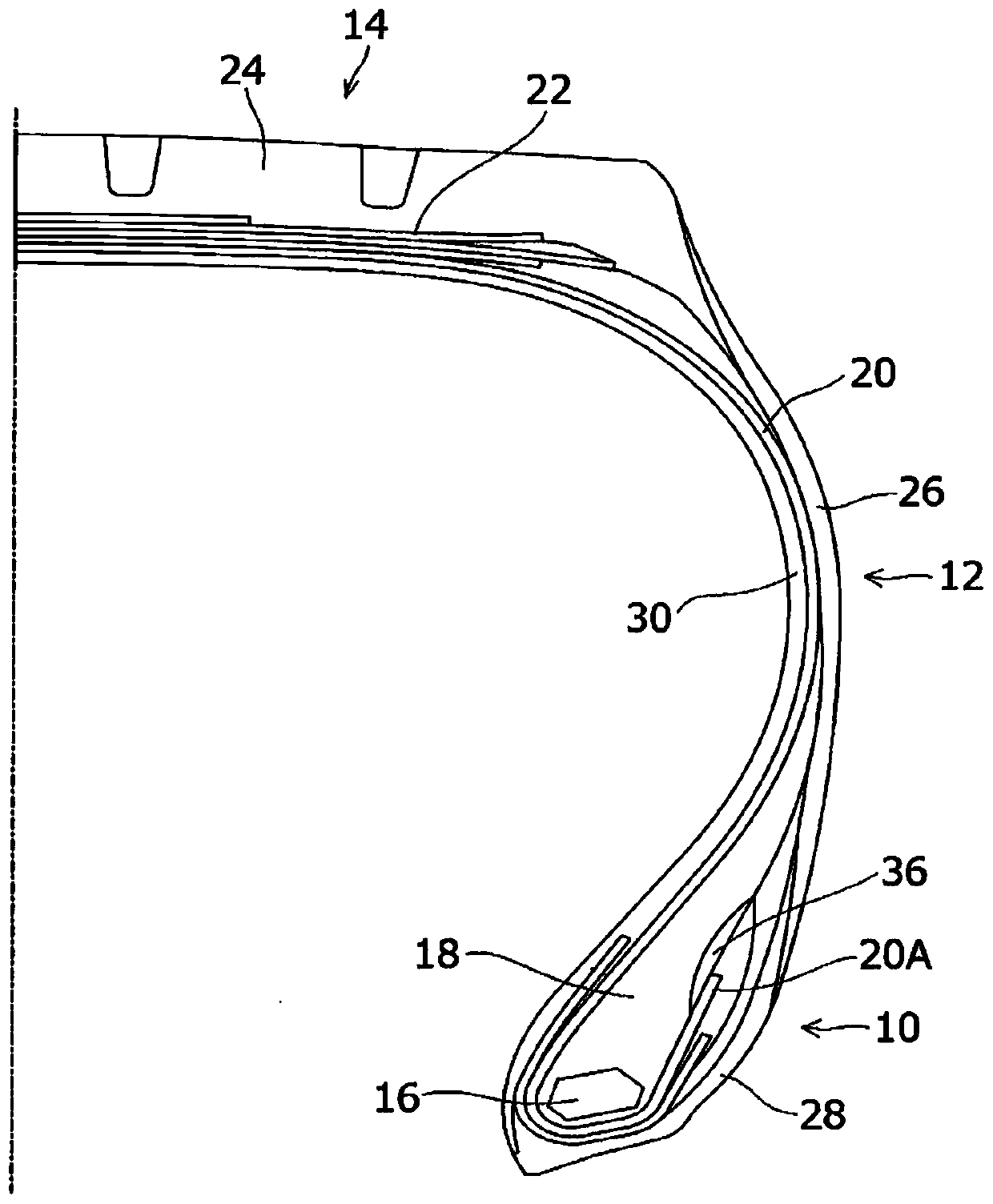

[0027] A pneumatic tire according to one embodiment includes a pair of bead portions 10 , a pair of sidewall portions 12 extending outward in the tire radial direction from the bead portions 10 , and a tread portion provided between the pair of sidewall portions 12 . 14.

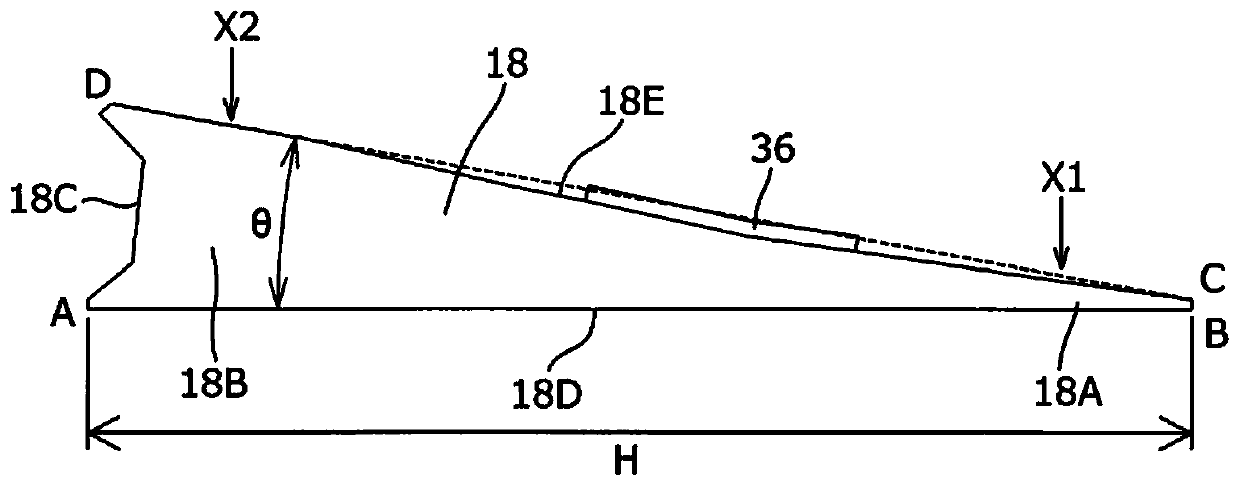

[0028] An annular bead core 16 and an annular bead cover 18 disposed on the outer peripheral side of the bead core 16 are respectively embedded in the pair of bead portions 10 . The bead core 16 is coated with a constricting body such as a steel wire with rubber, and in this example, the cross-sectional shape of the bead core 16 is substantially hexagonal. The bead cover 18 is made of hard rubber and is a rubber member having a cross-sectional shape that becomes narrower toward the tip.

[0029] An annular carcass ply 20 is disposed between the pair of bead portions 10 . The carcass ply 20 is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com