Pattern-making and sleeve-matching method for non-deviated rotator cuff clothing

A technology for raglan sleeves and clothing, applied in the field of clothing design and plate making, can solve the problems that the raglan sleeve matching technology is easy to move backward, cannot be applied, and affects the employment and future of technical personnel in the industry, so as to improve the quality of teaching and the employment rate. , the effect of promoting quality upgrade and conducive to prosperity and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings of the description: the matching sleeve object is (women's clothing), model 160 / 84, M number; fabric woolen; specification size:

[0028] Bust: 116cm

[0029] Total shoulder width: 39.6cm

[0030] Back width: 19.2cm (radius)

[0031] Chest width: 18.5cm (radius)

[0032] Total sleeve arch: 55.7cm (rear sleeve arch 27.5cm, front sleeve arch 28.2cm)

[0033] One sleeve Sleeve length: 58cm

[0034] Sleeve fat: 22cm (radius)

[0035] Cuffs: 17.5cm (radius)

[0036] The total consumption of Xiushan is 1cm (0.5cm before and after).

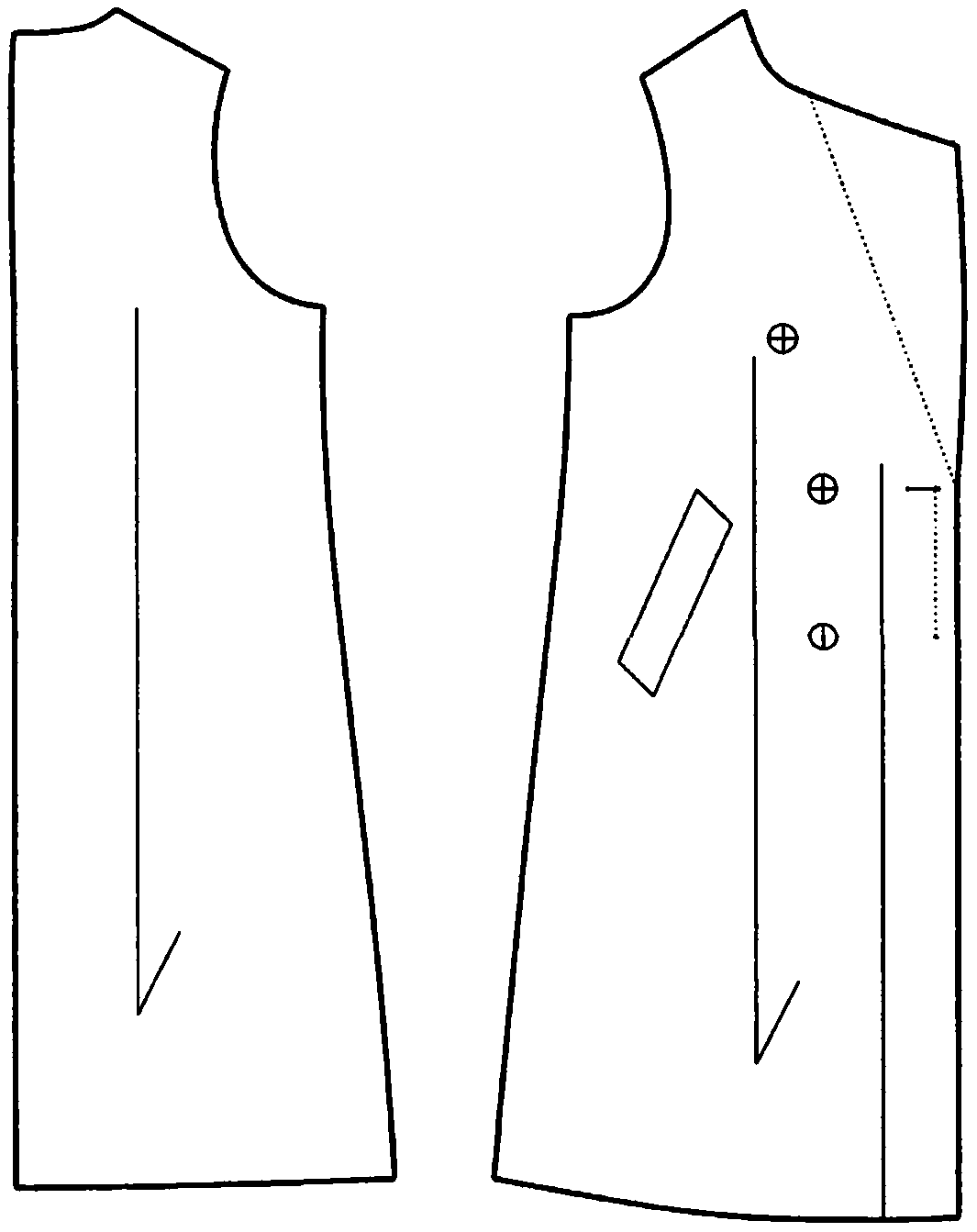

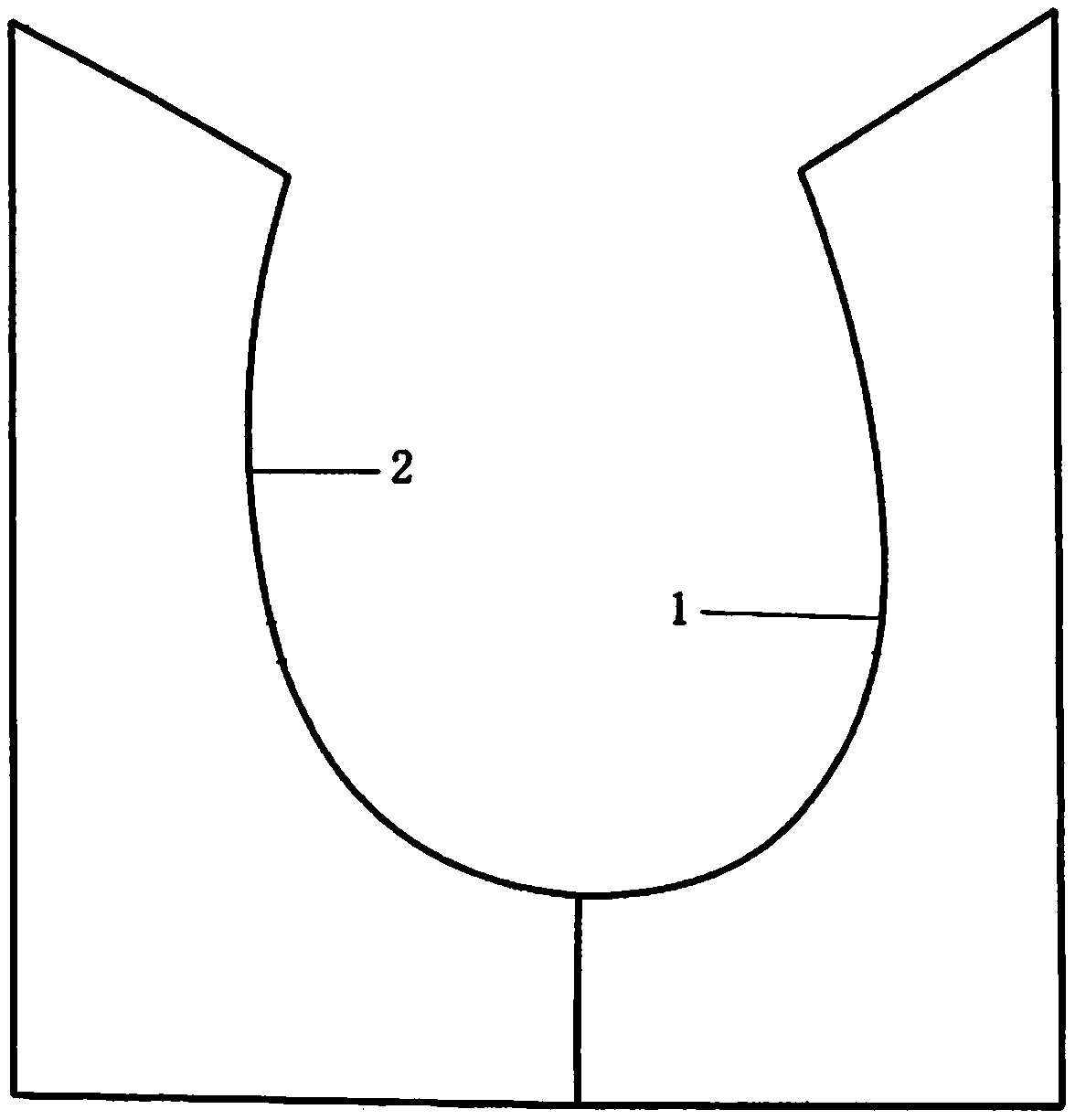

[0037] Such as Figure 1 to Figure 13 Shown, a kind of unbiased raglan sleeve clothing plate-making matching sleeve method of the present invention comprises the following steps:

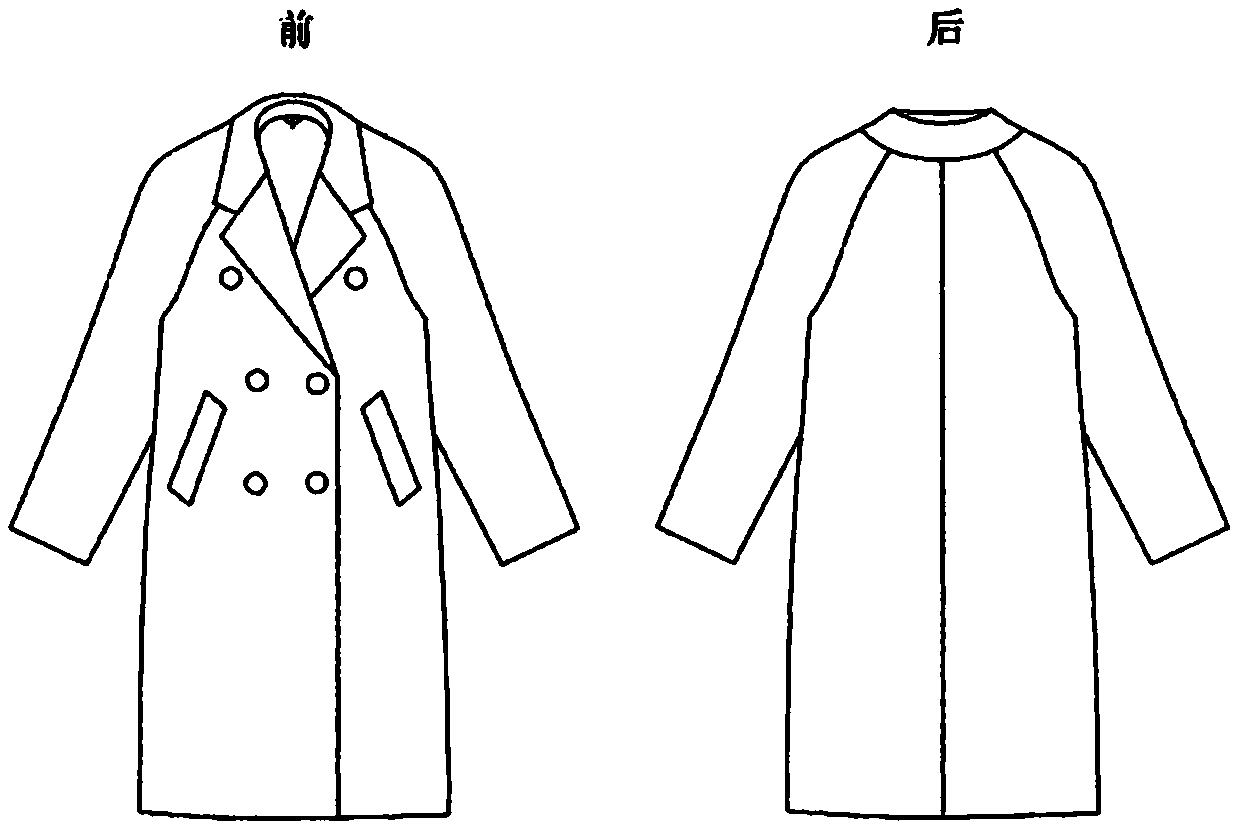

[0038] according to figure 1 For the style drawing of raglan sleeves, the front and back parts of the body must be drawn first. Make sure that the body is balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com