A vertical cold inlay device and inlay method for small ceramic matrix composite materials

A composite material and ceramic-based technology, which is applied in the field of vertical cold mounting devices for small ceramic-based composite materials, can solve the problem of inapplicable small ceramic-based composite materials for vertical mounting and fixing, the inability to freely change the relative position of the sample, and the non-adjustable position of the thin-section sample, etc. problems, to achieve the effect of small operation difficulty, avoid breakage, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

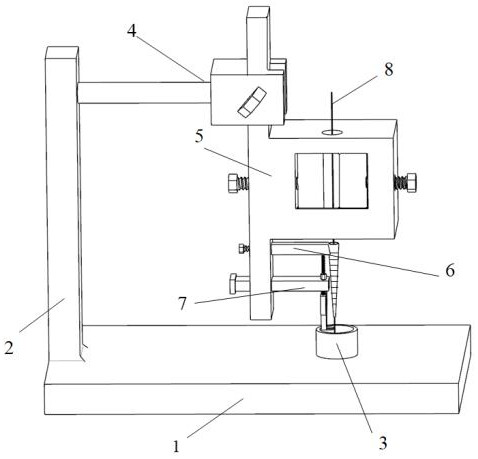

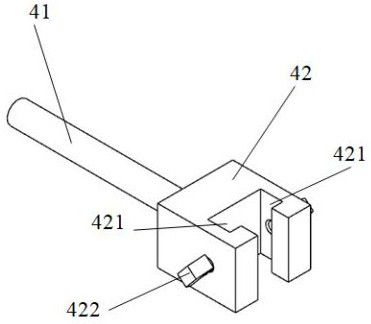

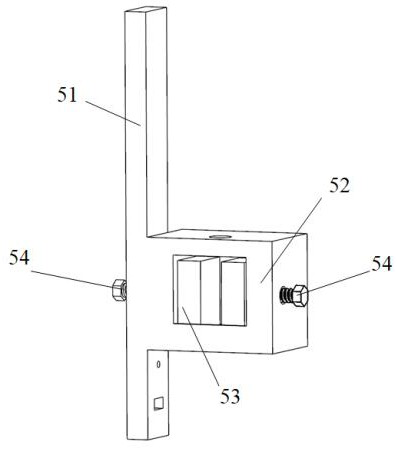

[0040] like figure 1 As shown, a vertical cold mounting device for small ceramic-based composite materials, which includes a base 1, a vertical column 2, a mosaic mold 3, a horizontal fixing device 4, a vertical moving device 5, a vertical fixing device 6 and a cutting device 7; , the vertical column 2 is vertically arranged, the lower end of the vertical column 2 is fixed on the base 1, the inlay mold 3 is detachably fixed on the upper surface of the base 1, the inlay mold 3 is a barrel-shaped structure with a closed lower end, and the horizontal fixing device 4 Including beam 41 and chuck 42, one end of beam 41 is fixedly connected to the upper part of the vertical column 2, and the other end is fixedly connected to chuck 42, and the fastening knob 422 is installed on the chuck 42 to adjust the tightness of the chuck 42, the vertical movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com