Testing device and method capable of achieving up-and-down climbing in counter-force well and turnover plate standing

A technology of test device and flap, which is applied in the direction of ladders, buildings, building structures, etc., can solve the problems of inconvenient handling of straight ladders or ladders, lack of guarantee of personnel safety, poor test efficiency, etc., and achieve saving Effects of working time, saving space, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments. The following examples are illustrative only to aid in the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, several improvements and modifications can also be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

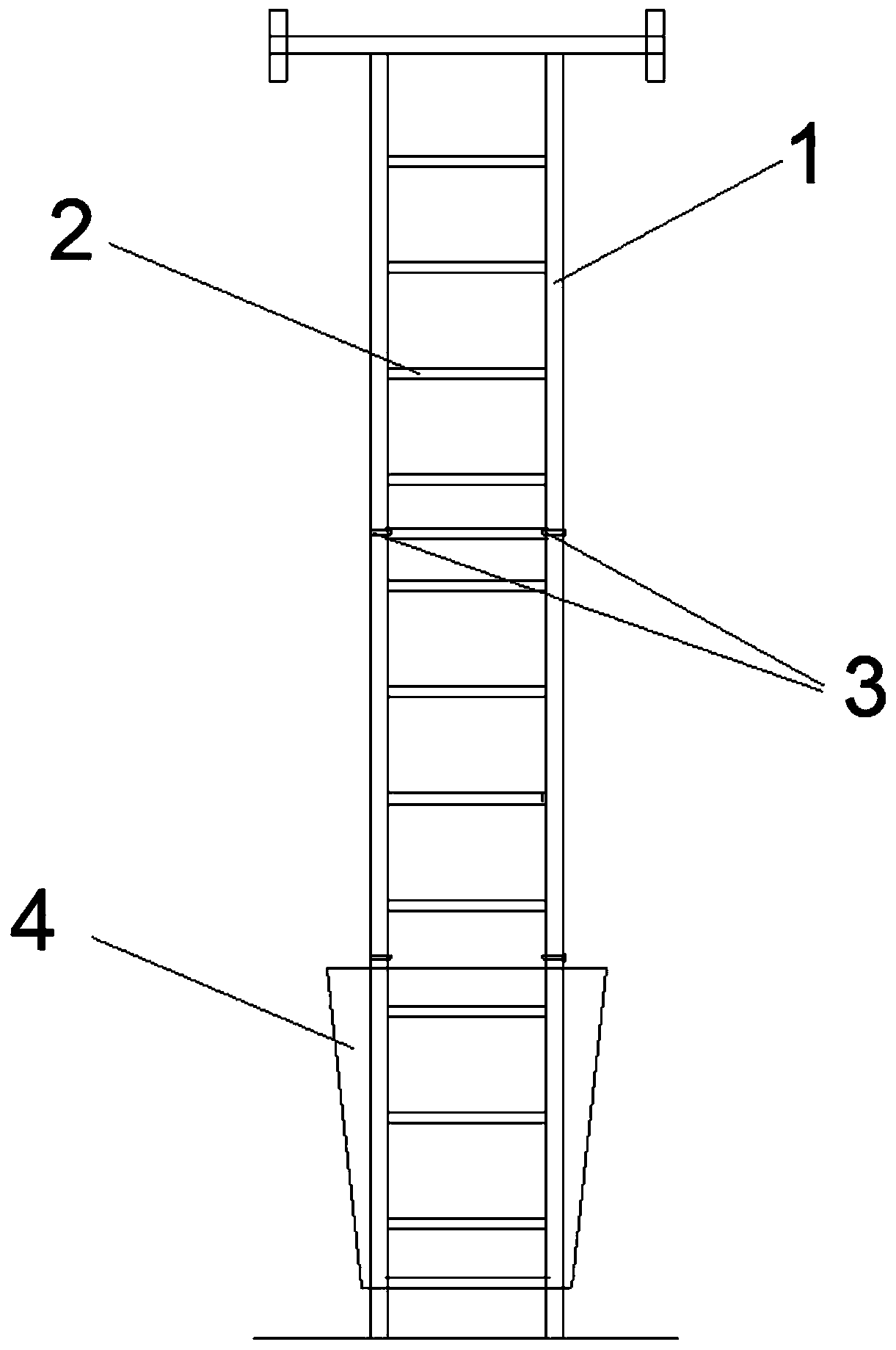

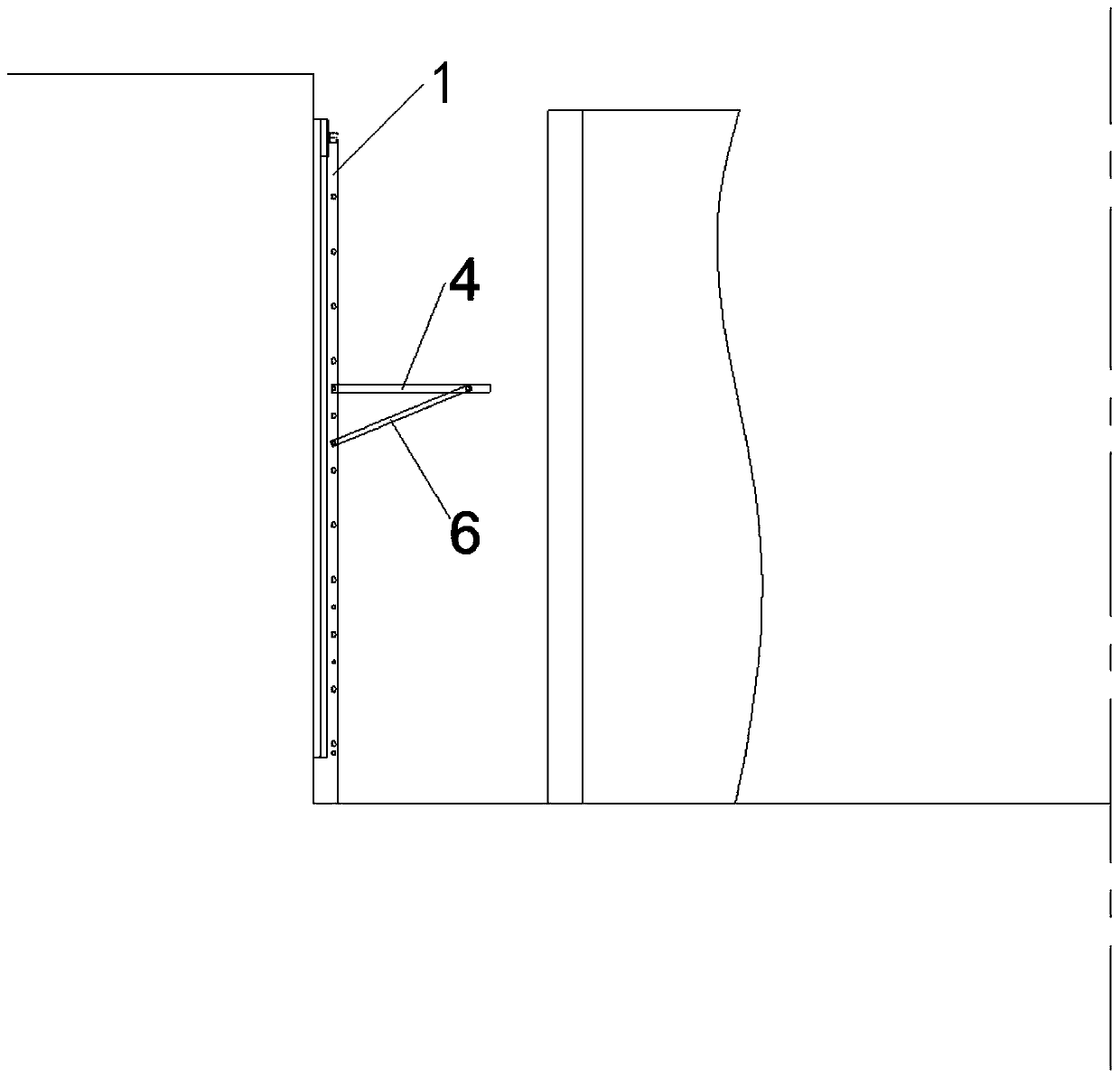

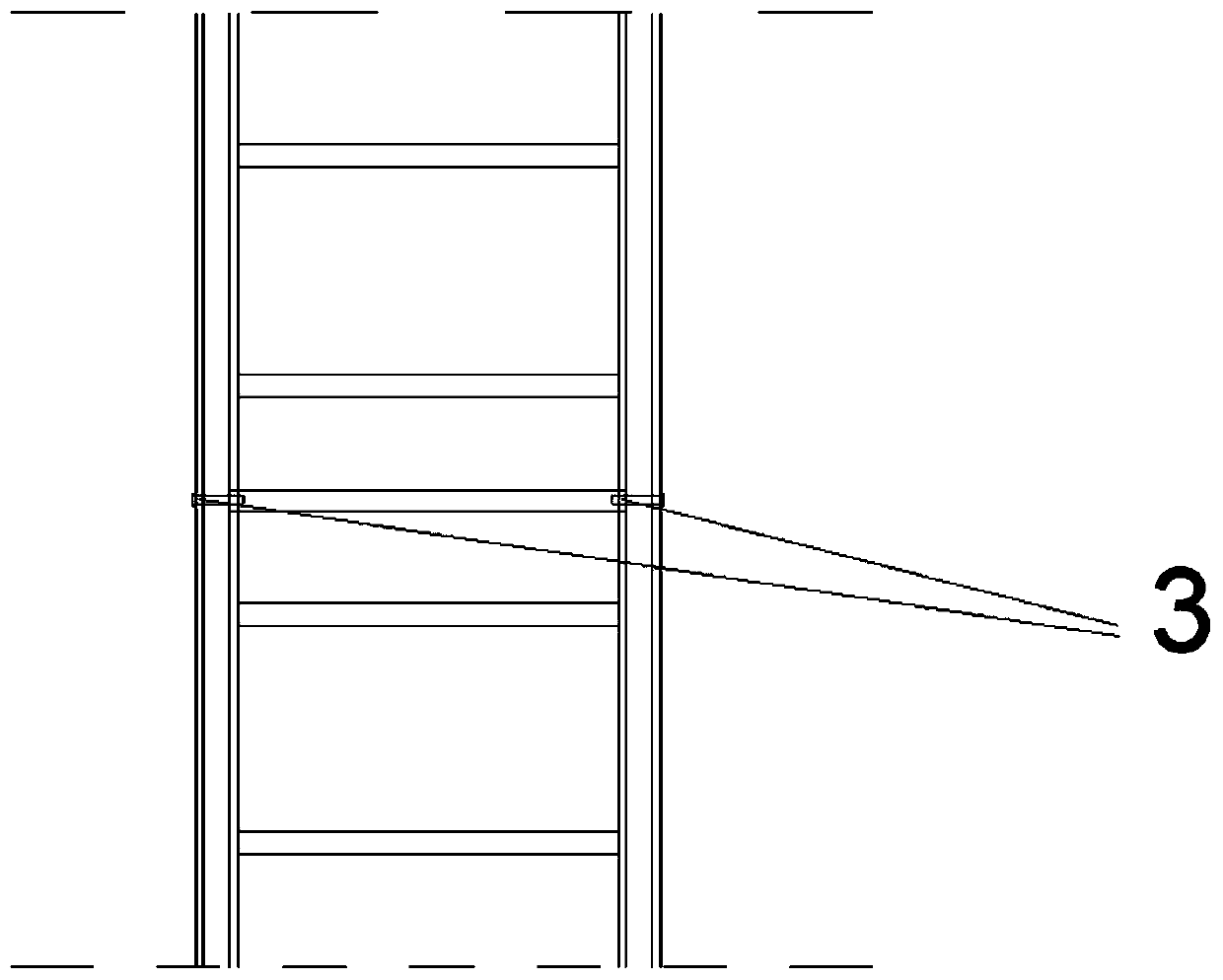

[0032] like figure 1 and figure 2 Shown, respectively, are the front view and side view of the overall ladder device. figure 2 It shows that the whole ladder device is installed in parallel with the shaft wall, and such a device and installation method can save the space between the segment and the shaft wall as much as possible. like figure 1 As shown in the figure, the pin shaft hole 3 is located on the step edge 1 in the middle part of the two cross bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com