Magnetorheological fluid-based brake-by-wire pedal simulator and working method thereof

A technology of pedal simulator and brake pedal, which is applied in the direction of brakes, brake action activation devices, foot activation devices, etc., to achieve the effects of smooth feedback, good comfort, universal applicability, and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

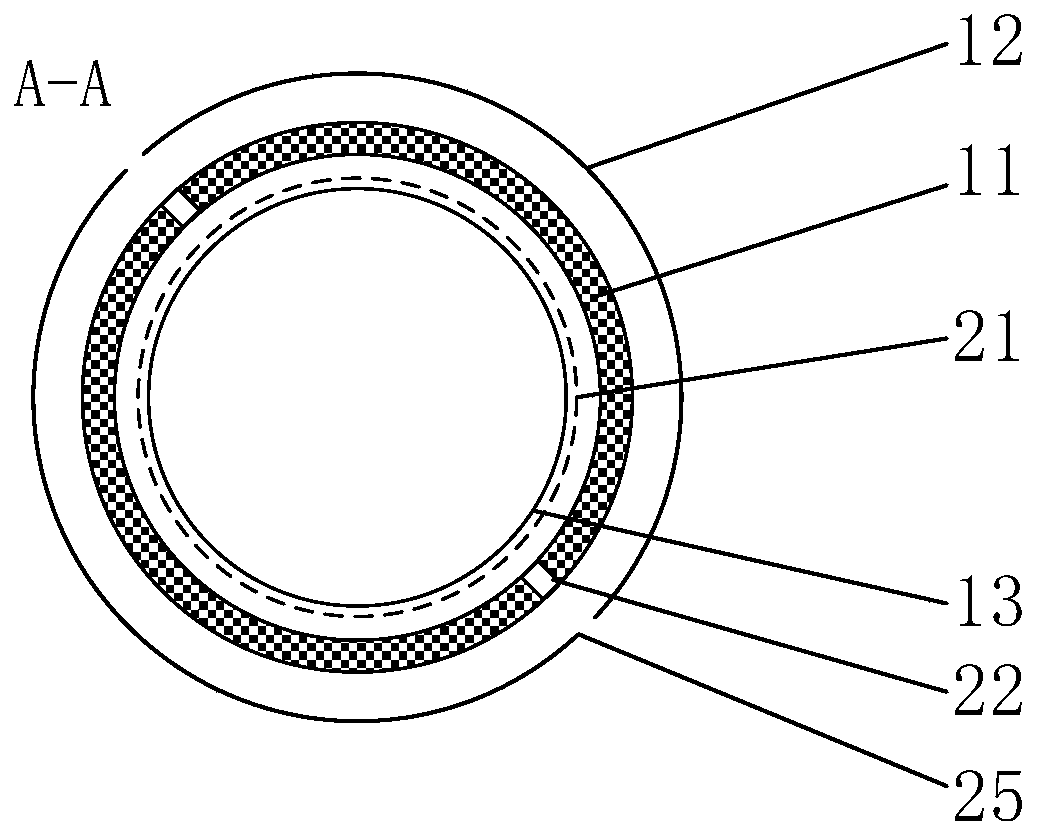

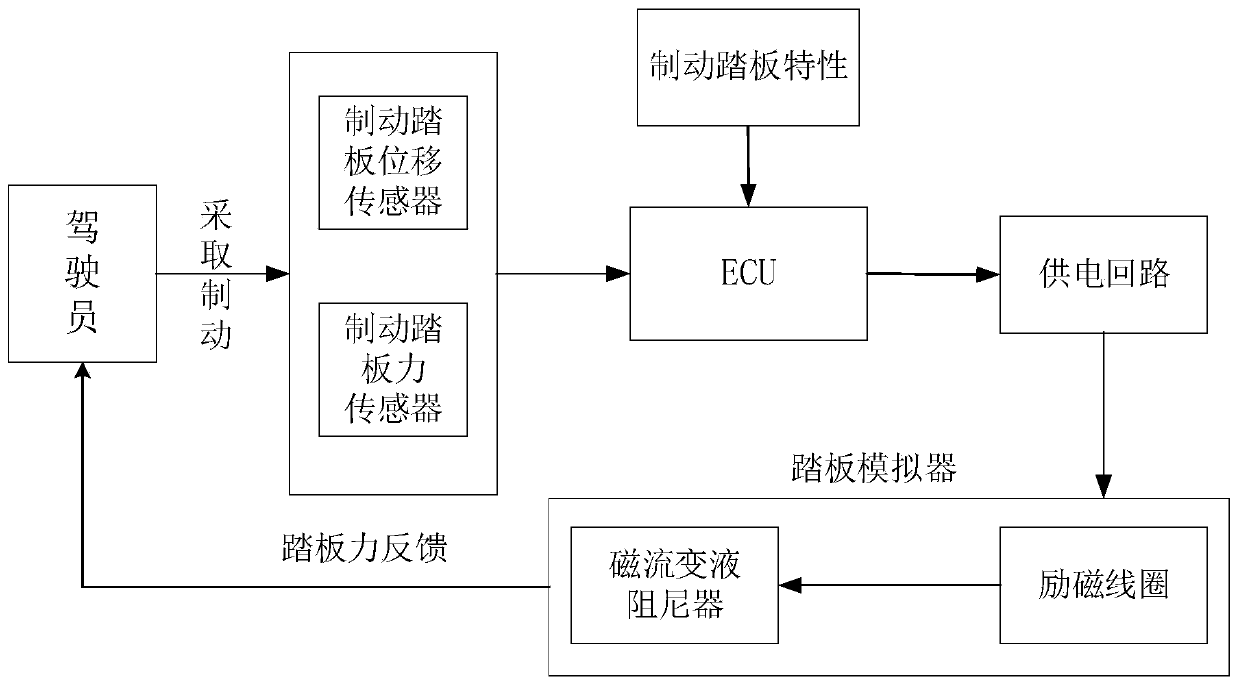

[0037] refer to figure 1 , figure 2 As shown, a magneto-rheological fluid-based brake-by-wire pedal simulator of the present invention includes: a mechanical transmission module, a brake pedal feeling simulation module and a control module;

[0038] The mechanical transmission module includes: brake pedal 2, pedal shaft 3, connecting rod 14 and push rod 15;

[0039] The input end of the pedal rotating shaft 3 is fixedly connected with the output end of the brake pedal 2, and the output end is fixedly connected with the input end of the connecting rod 14; the output end of the connecting rod 14 is connected with the input end of the push rod 15 Articulation;

[0040] The brake pedal feelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com