Punching and cutoff mold for left support and right support of automobile

A punching and automobile technology, applied in the field of auto parts processing, can solve the problems of unfavorable large-scale production of the left and right brackets of the front beam of the car, increase the labor intensity of workers, and many processing procedures, so as to shorten the production cycle, facilitate production management, The effect of fewer molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

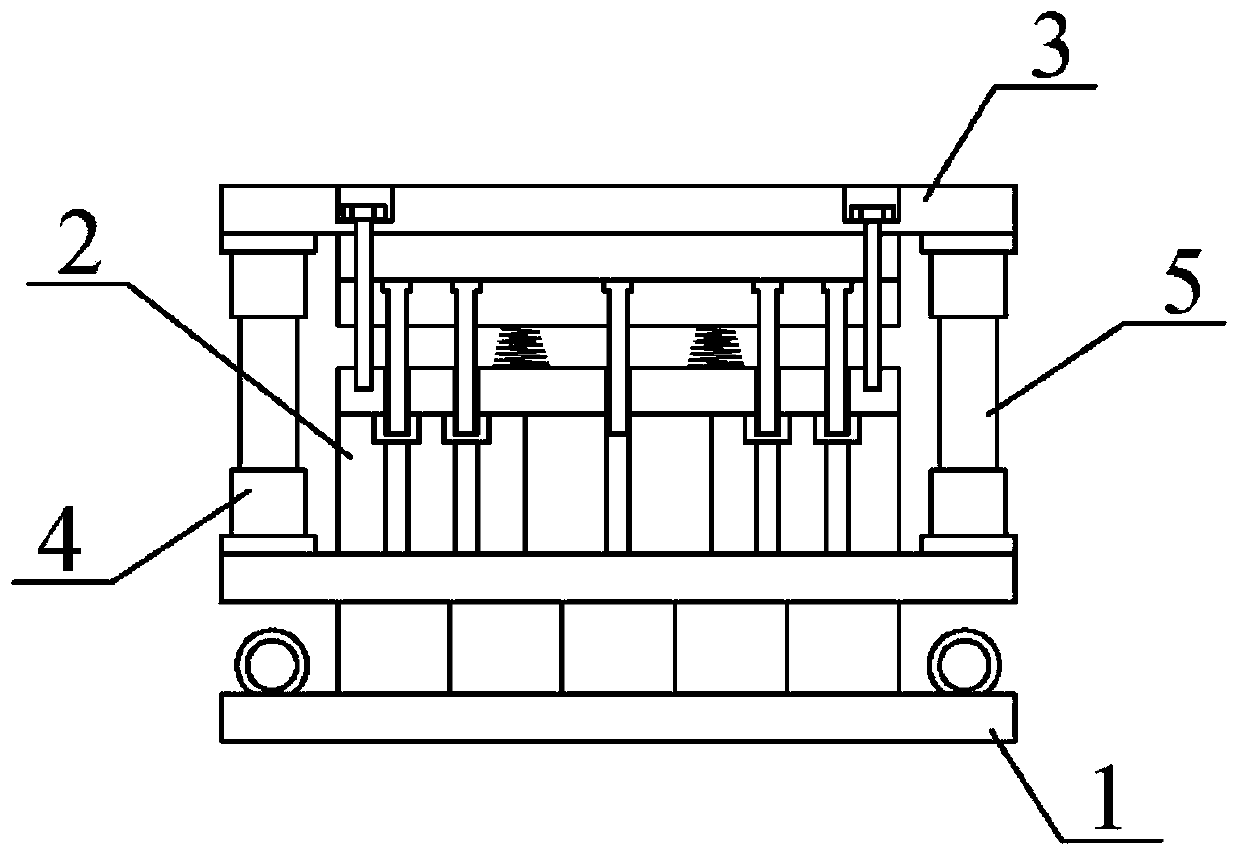

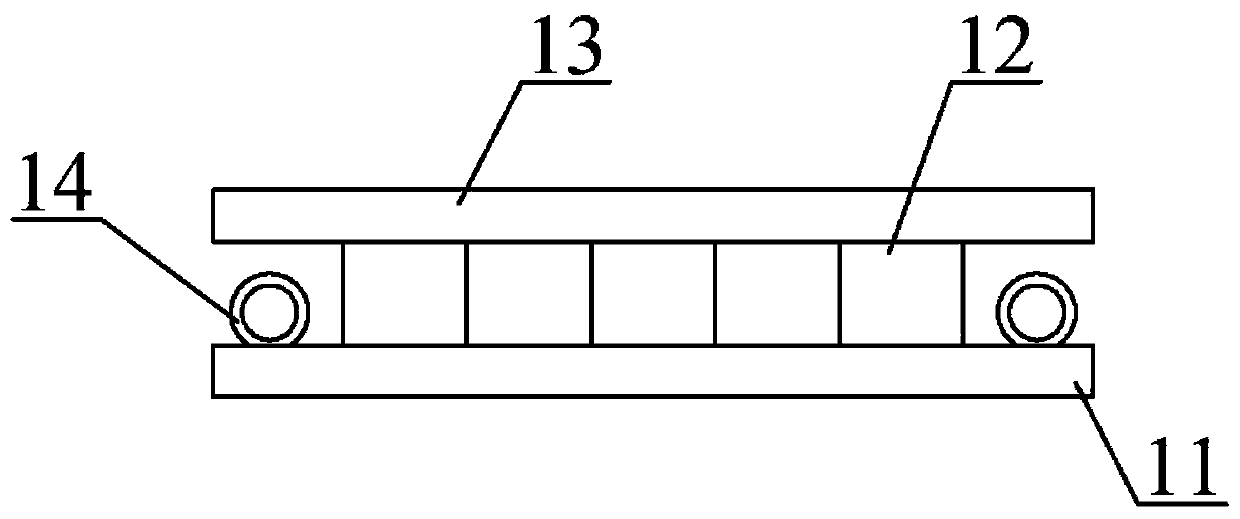

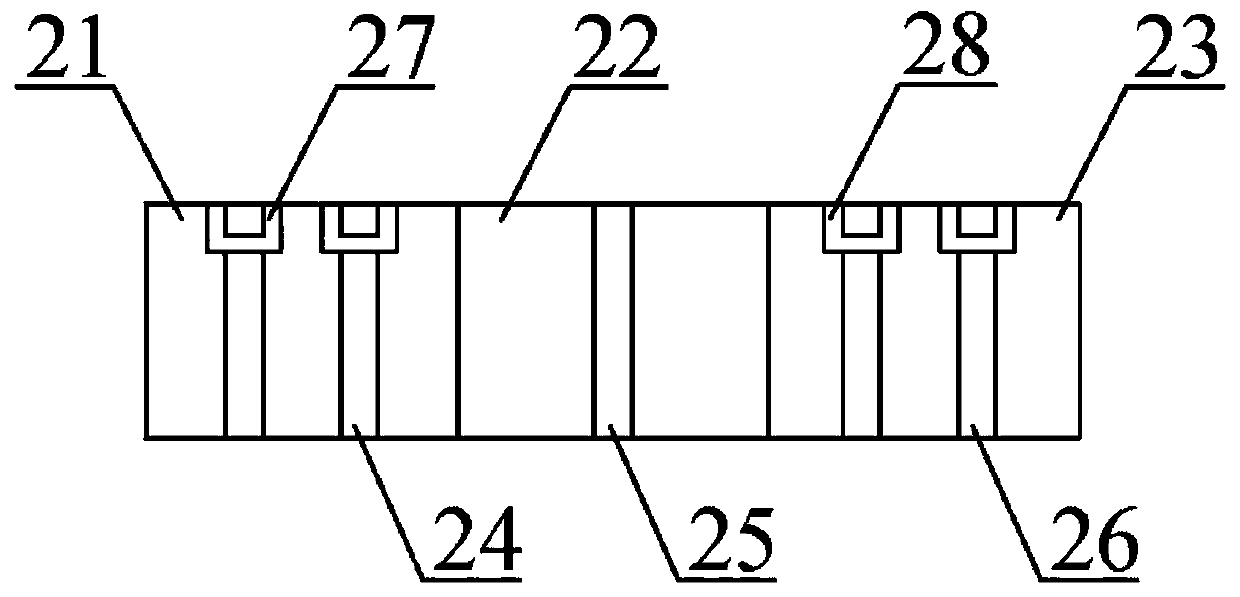

[0024] like Figure 1-4 As shown, the present invention provides a technical solution: a punching and cutting mold for the left and right brackets of automobiles, including a support mechanism, a lower mold mechanism, an upper mold mechanism, a guide sleeve and a guide column, and the lower mold mechanism is fixed on the support by bolts. The middle position above the mechanism; four guide sleeves are used, and the guide sleeves are fixed on the upper four corners of the support mechanism by bolts, and guide holes are opened on the inner side of the guide sleeves; the upper mold mechanism is arranged above the lower mold mechanism ; The guide column adopts four, and the guide column is fixed on the lower four corners of the upper die mechanism by bolts, and the lower end of the guide column is located inside the guide hole of the guide sleeve, wherein the size of the guide column matches the size of the guide sleeve; The support mechanism includes a lower footboard, a backing ...

Embodiment 2

[0026] A punching and cutting die for the left and right brackets of an automobile, comprising a support mechanism, a lower mold mechanism, an upper mold mechanism, a guide sleeve and a guide post, the lower mold mechanism is fixed at the middle position above the support mechanism by bolts; the guide sleeve Four are used, and the guide sleeve is fixed on the upper four corners of the support mechanism by bolts, and the inner side of the guide sleeve is provided with a guide hole; the upper mold mechanism is arranged above the lower mold mechanism; four guide columns are used, and The guide column is fixed on the lower four corners of the upper mold mechanism by bolts, and the lower end of the guide column is located inside the guide hole of the guide sleeve, wherein the size of the guide column matches the size of the guide sleeve; the supporting mechanism includes a lower foot plate, a backing plate, Lower die base and lifting lugs; four lifting lugs are used, and the lifting...

Embodiment 3

[0030] A punching and cutting die for the left and right brackets of an automobile, comprising a support mechanism, a lower mold mechanism, an upper mold mechanism, a guide sleeve and a guide post, the lower mold mechanism is fixed at the middle position above the support mechanism by bolts; the guide sleeve Four are used, and the guide sleeve is fixed on the upper four corners of the support mechanism by bolts, and the inner side of the guide sleeve is provided with a guide hole; the upper mold mechanism is arranged above the lower mold mechanism; four guide columns are used, and The guide column is fixed on the lower four corners of the upper mold mechanism by bolts, and the lower end of the guide column is located inside the guide hole of the guide sleeve, wherein the size of the guide column matches the size of the guide sleeve; the supporting mechanism includes a lower foot plate, a backing plate, Lower die base and lifting lugs; four lifting lugs are used, and the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com