Forming die for expanded metal meshes for supplementary restraint systems

A technology for forming molds and airbags, which is applied in the field of expanded metal forming molds for airbags, can solve problems such as unqualified products and low processing efficiency, achieve high processing and forming efficiency, and improve the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

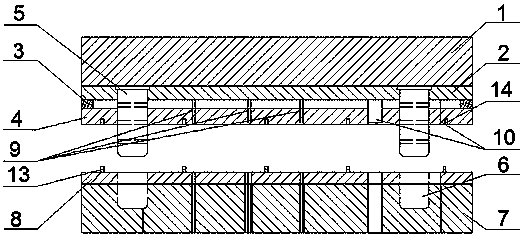

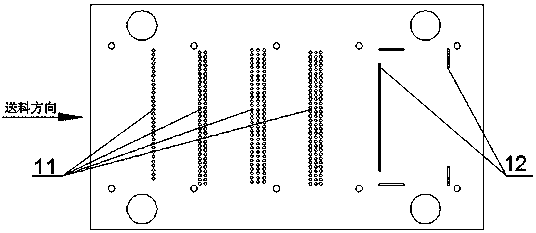

[0012] An expanded metal forming die for an airbag provided by the present invention includes an upper die and a lower die, and an inner guide post 5 and an inner guide sleeve 6 for guiding fit are correspondingly provided between the upper die and the lower die. The upper mold includes an upper mold base 1, an upper mold plate 2 and a material stripping plate 4, the upper mold plate 2 is fixed on the bottom of the upper mold base 1, and the stripping plate 4 is arranged at an interval relative to the upper mold plate 2, and is separated by four corners. The elastic connector 3 is hoisted below the upper template 2, and the punching needle group 9 and the cutting knife group 10 are fixed in sequence on the bottom of the upper template 2 along the steel plate feeding direction; the lower mold includes a lower mold base 7 and is fixed on the lower mold base The lower mold plate 8 on the top of the mold base 7 is provided with a lower mold hole 11 and a lower knife groove correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com