A brushless motor with a single wire wrap

A motor and single-wire technology, applied in the field of motors, can solve the problems of front end cover breakage, motor damage, and front end cover detachment from the casing, etc., and achieve the effect of improving firmness and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

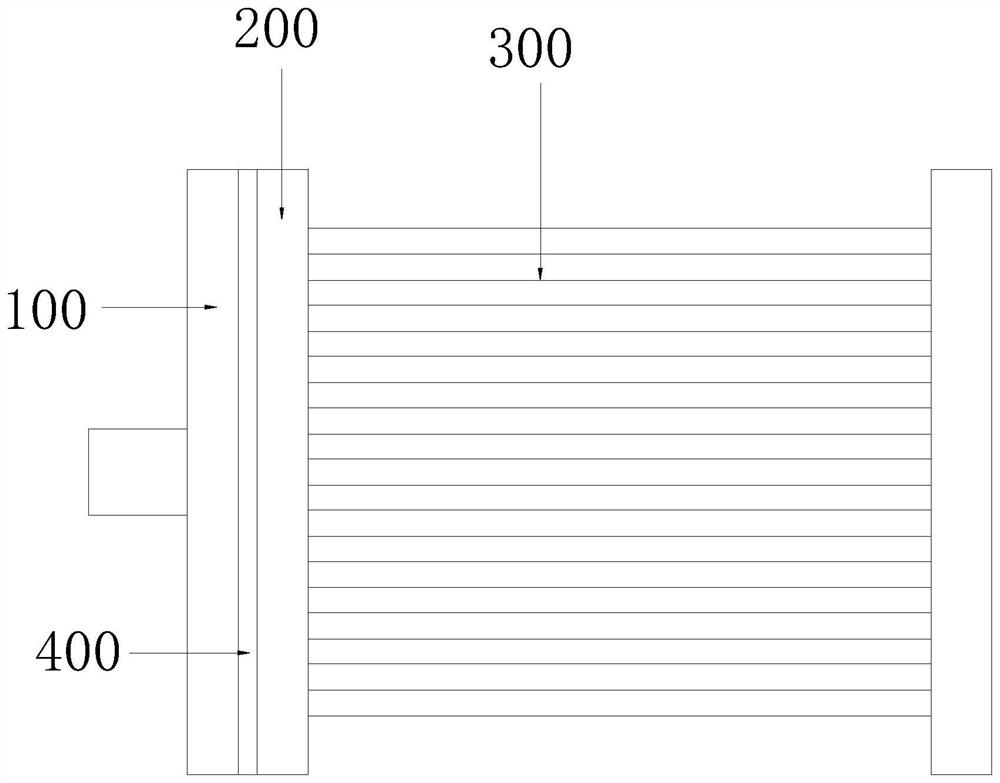

[0032] see Figure 1-8 , the present invention provides a technical solution of a brushless motor surrounded by single wires: its structure includes a front cover 100, a body 200, a heat sink 300, and a sealing ring 400, and the body 200 is evenly distributed with heat sinks arranged equidistantly 300, the body 200 is mechanically connected with a front end cover 100, and a sealing ring 400 is attached between the front end cover 100 and the body 200, and the setting of the sealing ring 400 is to improve the airtightness of the installation of the body 200 and the front end cover 100 ;

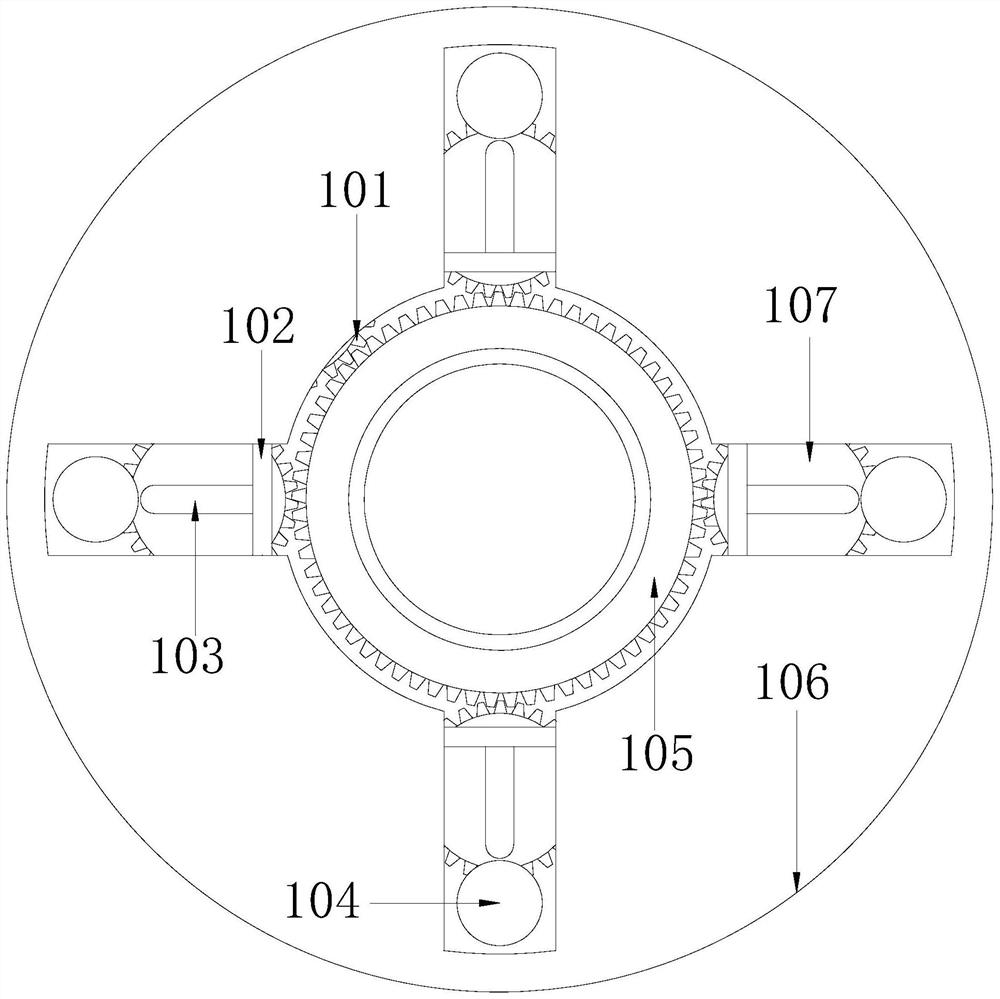

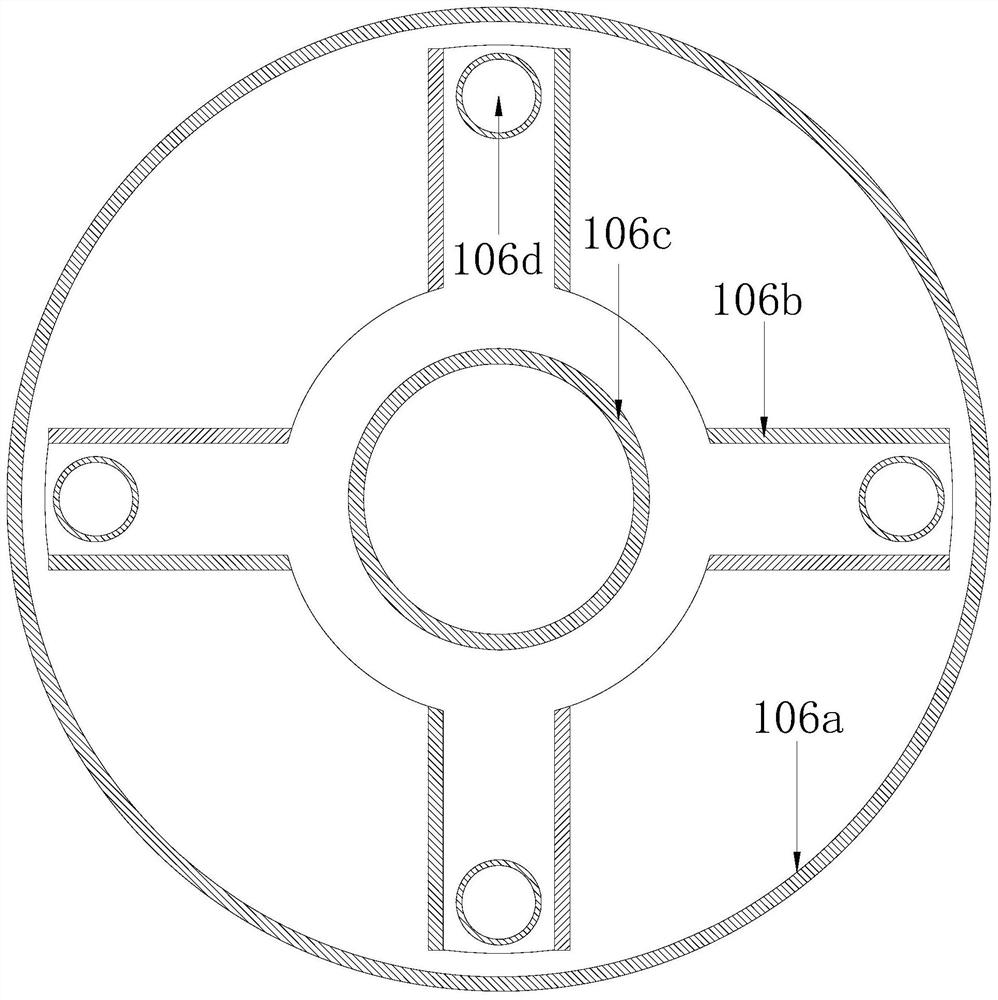

[0033] The front end cover 100 includes a rotation locking mechanism 101, a translation limit plate 102, a limit clamp column 103, an inner hexagon bolt 104, an adjustment gear 105, a cover body 106, and a rotation gear 107. The center of the cover body 106 An adjustment gear 105 is installed, and the four positive positions of the adjustment gear 105 are engaged with a rotation gear 107, and...

Embodiment 2

[0046] see Figure 1-3 , 8-10, the present invention provides a technical solution of a brushless motor surrounded by single wires: its structure includes a front end cover 100, a body 200, a heat sink 300, and a sealing ring 400, and equidistant patterns are evenly distributed outside the body 200. The provided heat sink 300, the body 200 is mechanically connected with the front end cover 100, and the sealing ring 400 is fitted between the front end cover 100 and the body 200, and the setting of the sealing ring 400 is to improve the tightness of installation;

[0047] see figure 2 , the front end cover 100 includes a rotation clamping mechanism 101, a translation limit plate 102, a limit clamp column 103, an inner hexagon bolt 104, an adjustment gear 105, a cover body 106, a rotation gear 107, and the cover body 106 The center is equipped with an adjustment gear 105, and the four positive positions of the adjustment gear 105 are meshed with a rotation gear 107, and one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com