An electrically driven motor base adjuster

A motor base and electric drive technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problem of damage to the service life of auxiliary structures such as motors and belts, the difficulty of ensuring the stability of the movable base support, and the stability of the motor base support. Contribution and other issues to achieve the effect of reducing acquisition cost, increasing slack, and reducing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

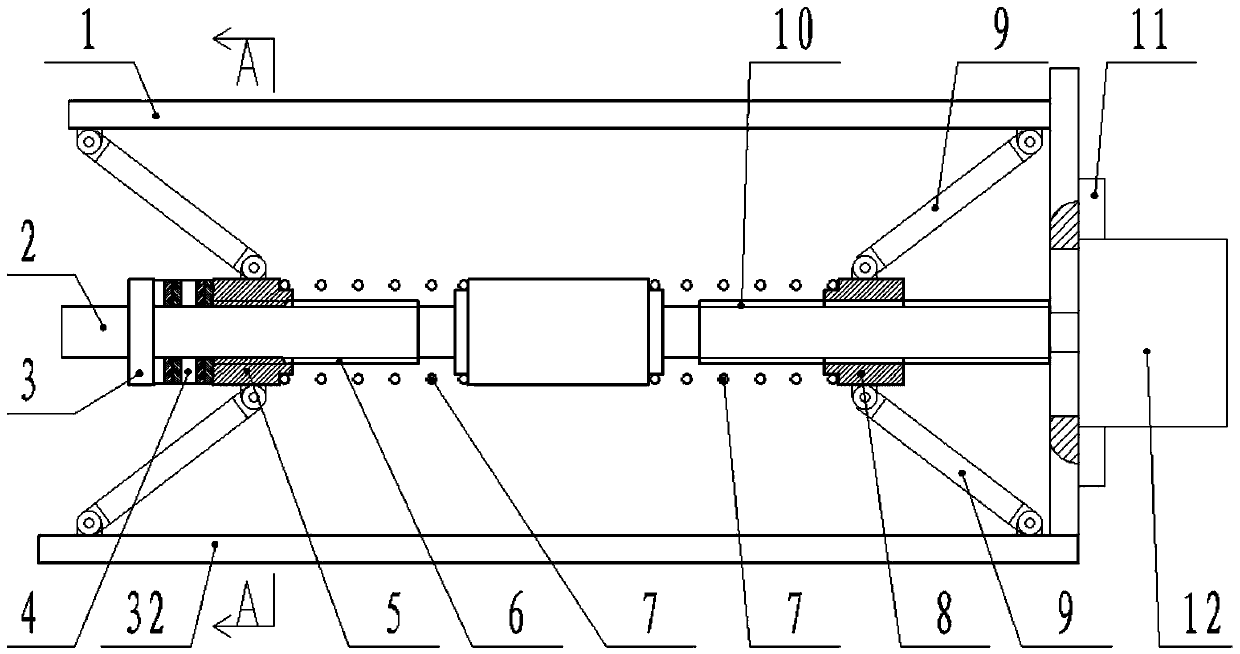

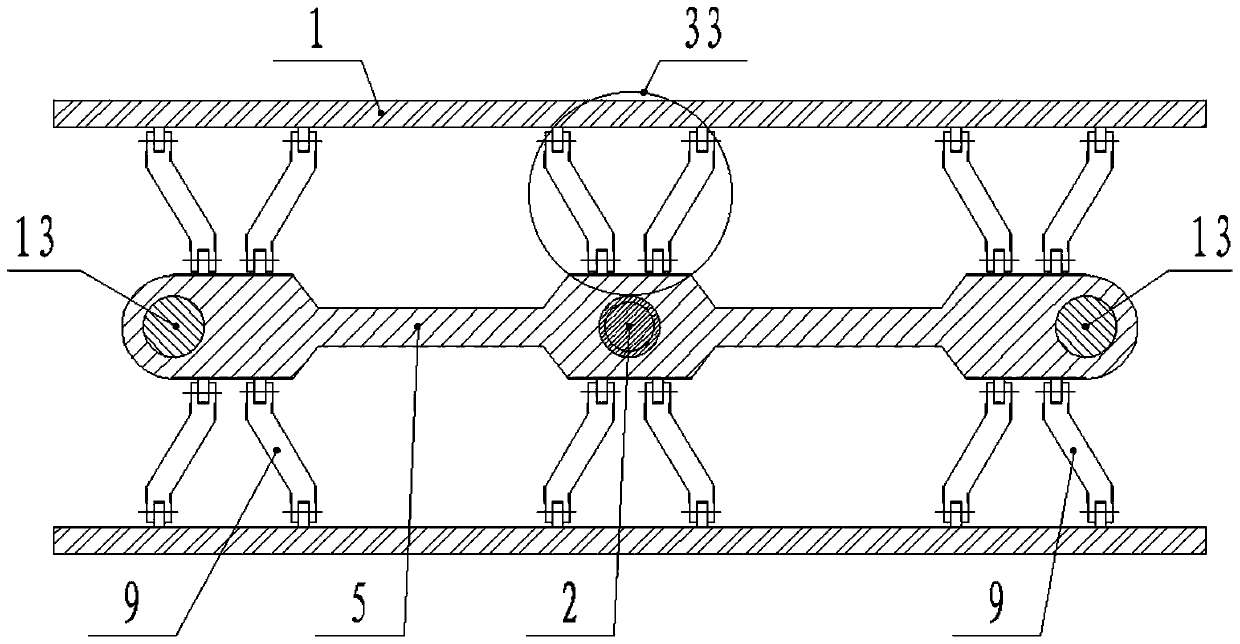

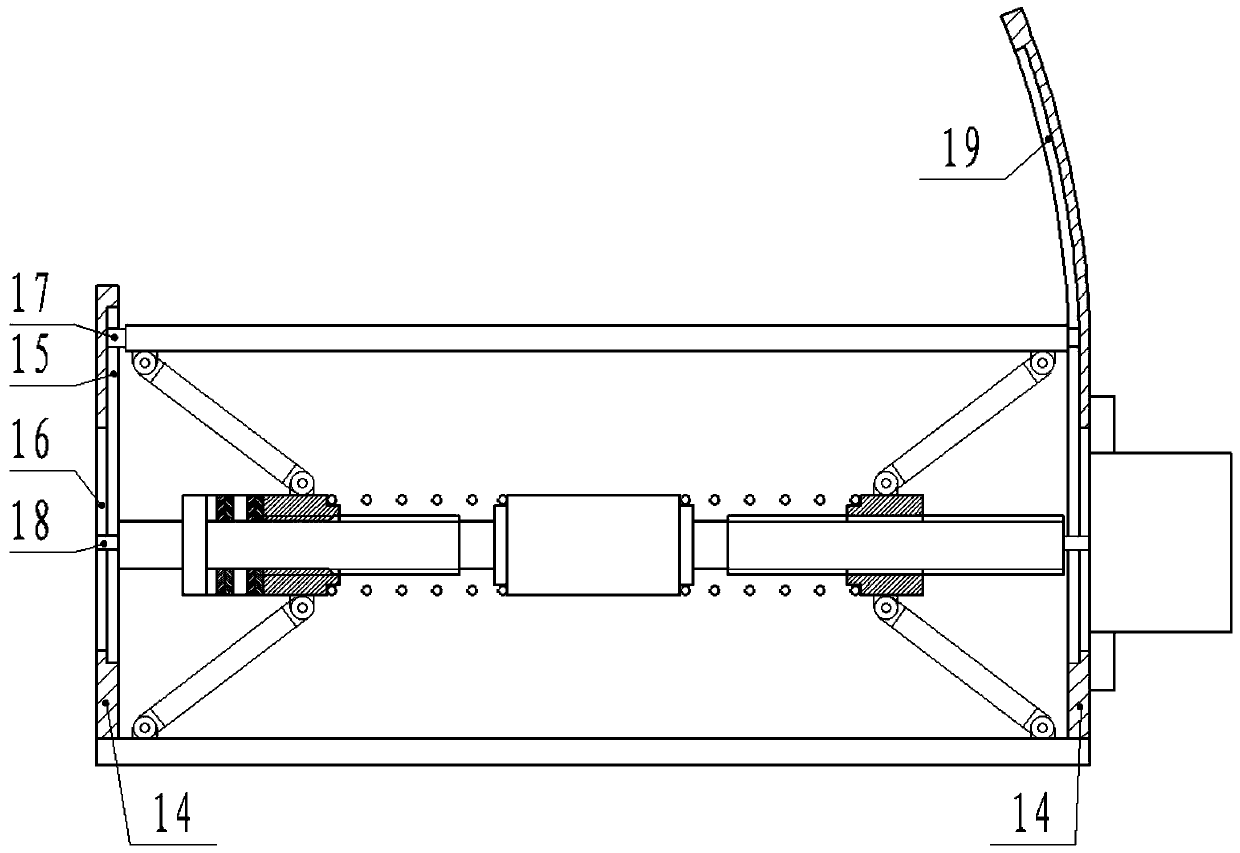

[0034] The present invention will be further described below in conjunction with accompanying drawing:

[0035] This embodiment includes an upper plate 1 and a lower plate 32, a drive mechanism is arranged between the upper plate 1 and the lower plate 32, and the upper plate 1 and the lower plate 32 move relatively under the action of the drive mechanism, thereby realizing the motor 20 of the pumping unit. Position adjustments. The above are existing structures in the prior art, and will not be repeated here.

[0036] The important innovation of the present invention is that: the driving mechanism between the upper plate 1 and the lower plate 32 is a lifting mechanism.

[0037] Most of the main drive belts on the existing beam pumping units are inclined, so the motor 20 of the pumping unit can adjust the tension of the belt by moving laterally and vertically. However, since the motor 20 of the pumping unit The self-weight of the self-weight can reach hundreds of kilograms us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com