Lightning arrester core winding device and winding method

A technology of winding device and lightning arrester, which is applied in the direction of overvoltage protection resistors, manufacturing encapsulation/housing resistors, varistors, etc. It can solve problems such as explosion, poor contact of resistor sheets, and easy gaps in resistor sheets, so as to avoid Effects of explosion, solving poor contact, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

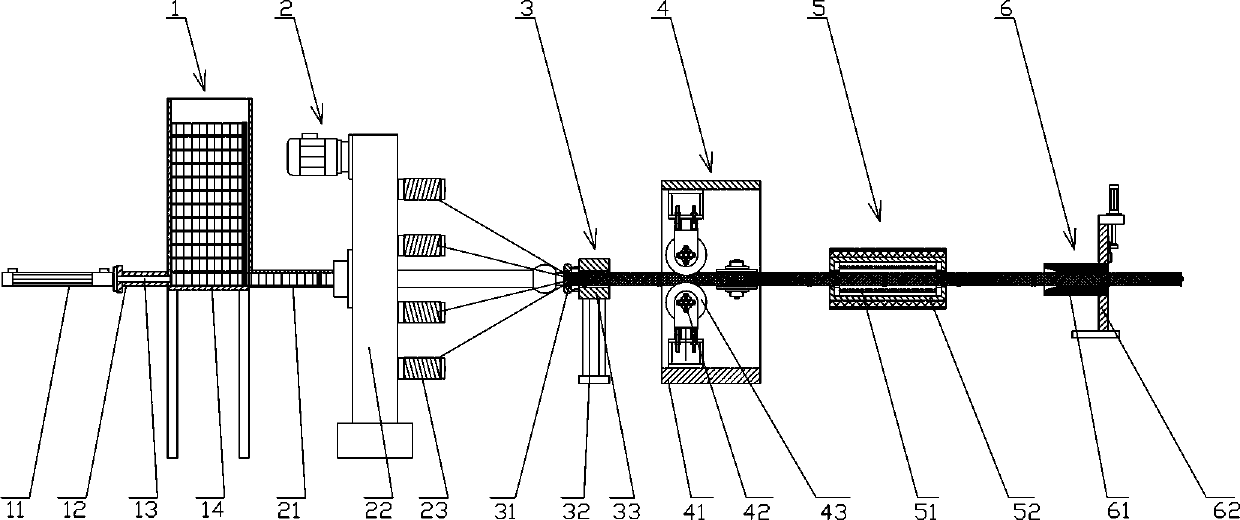

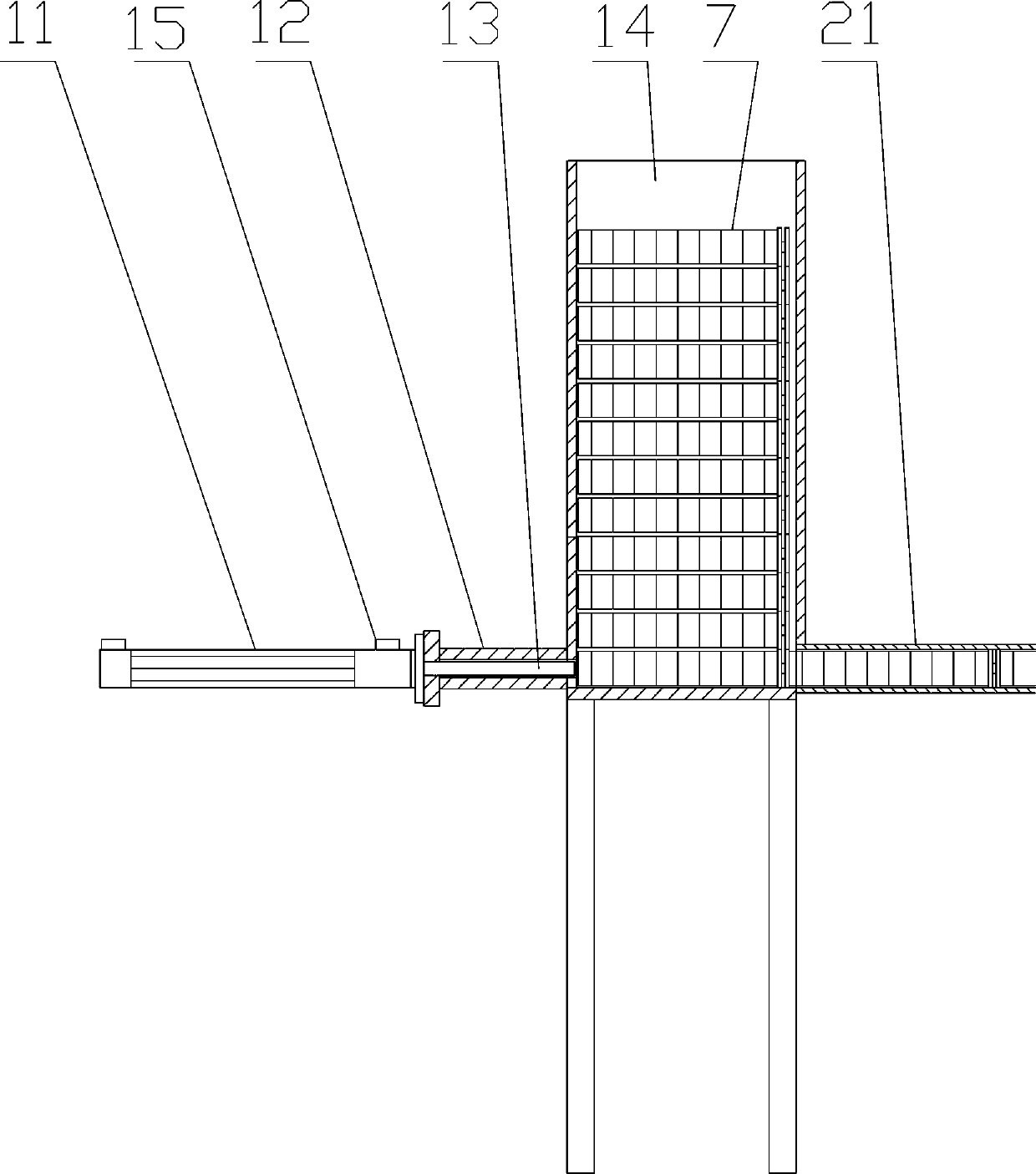

[0020] Such as Figures 1 to 5 As shown, a lightning arrester core winding device includes a low-speed braiding machine 2, and the braiding machine 2 includes a frame 22, a spindle 23 and a core tube 21, and each spindle 23 is wound with a glass fiber tape reel impregnated with epoxy resin , a limit mechanism 3, a damping mechanism 4 and a cutting device 6 are sequentially provided on one side of the knitting machine 2;

[0021] The limiting mechanism 3 includes a first bracket 33, and a first conduit 32 is arranged in the first bracket 33. One side of the first conduit 32 is fixedly connected with the limiting ring 31, and the core tube 21 passes through the arrester core 7 and passes through the limiting After the position ring 31 enters the first conduit 32, the distance between the position limit ring 31 and the core tube 21 is smaller than the thickness of the arrester core 7 resistance sheet;

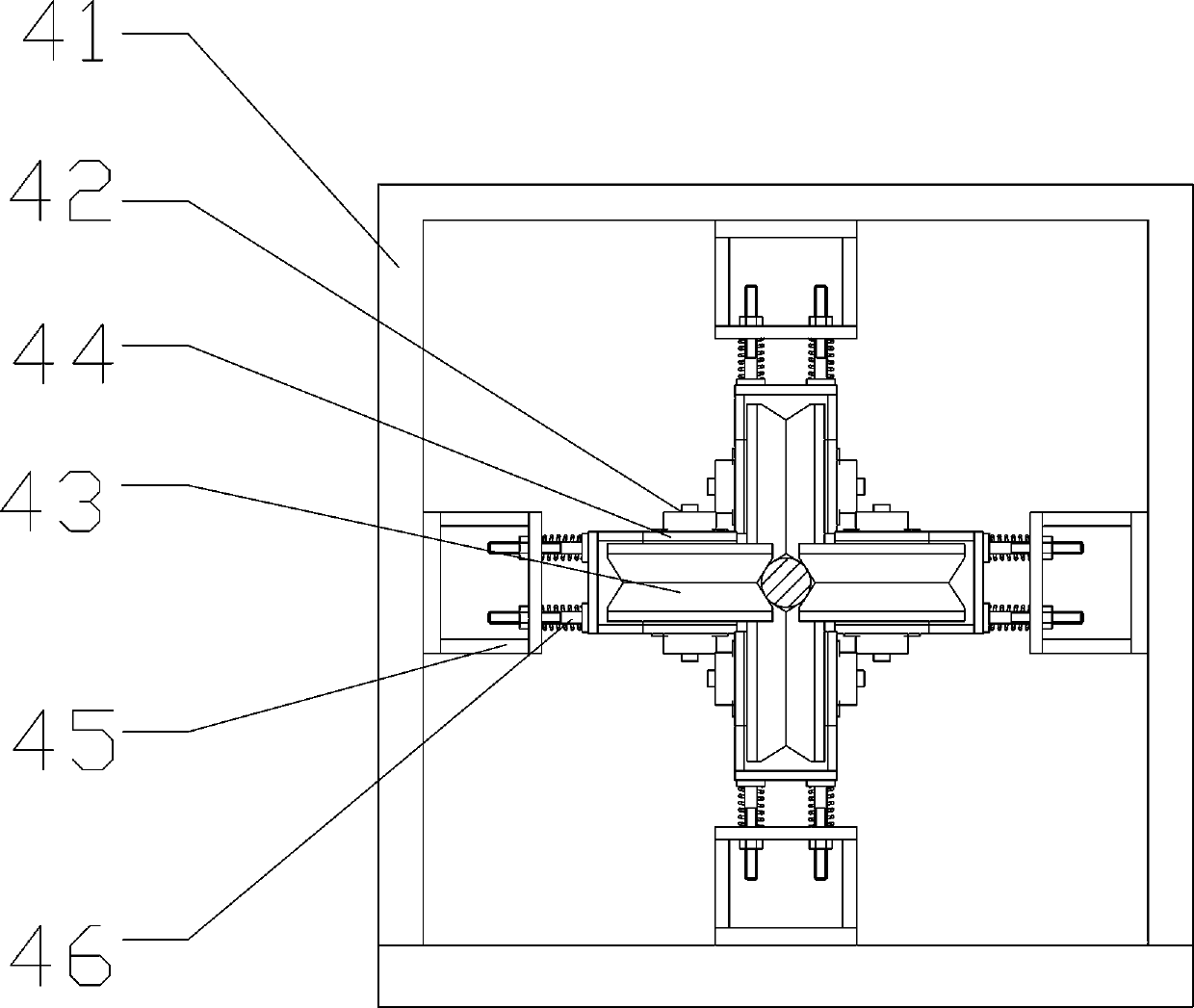

[0022] The damping mechanism 4 includes a frame 41, and four sheaves 43 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com