Cable eccentricity detection device

A detection device and eccentricity technology, applied in the direction of measuring device, using electrical device, using electromagnetic means, etc., can solve the problems of material waste, damage, breakdown, safety hazard, etc., and achieve the effect of high efficiency and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

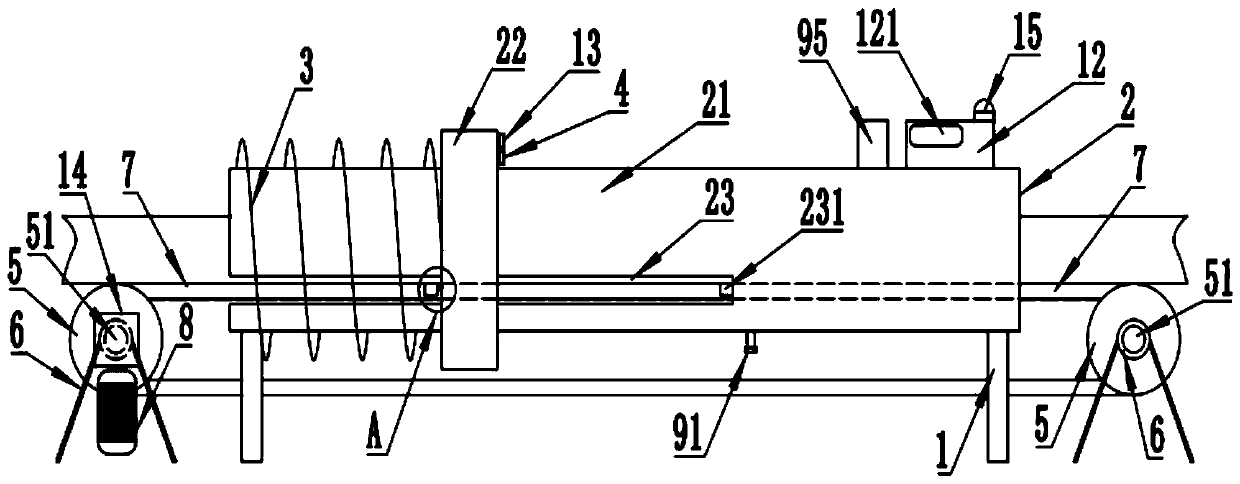

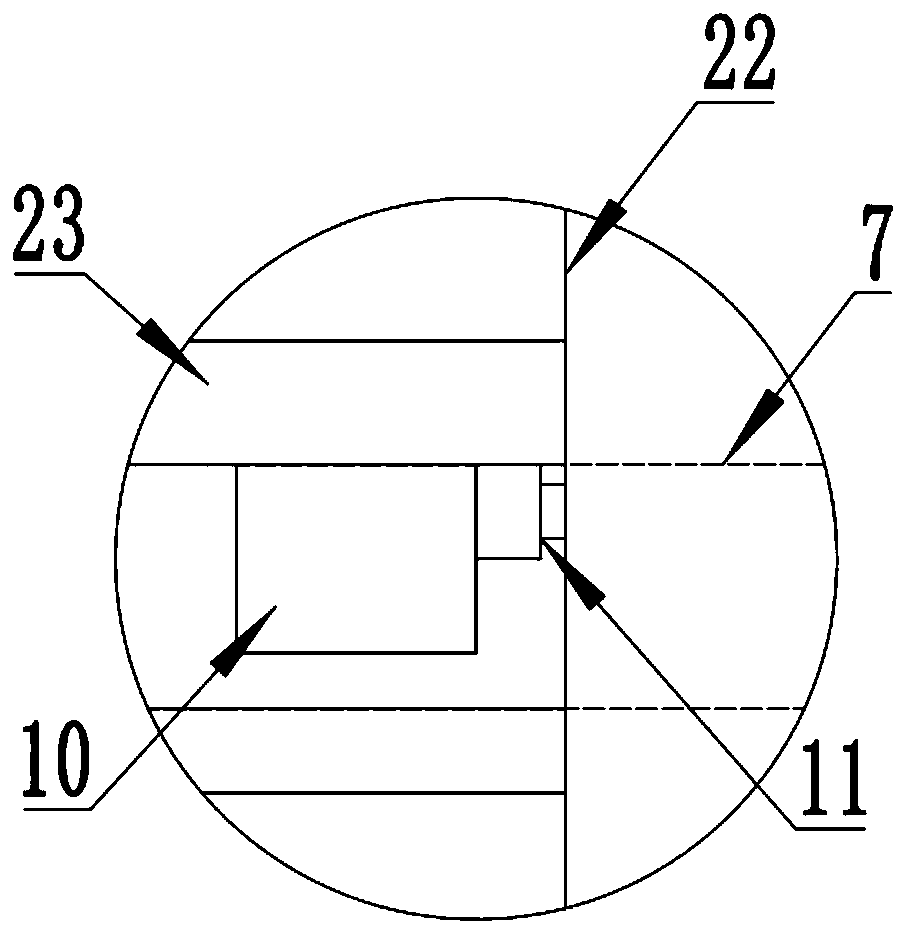

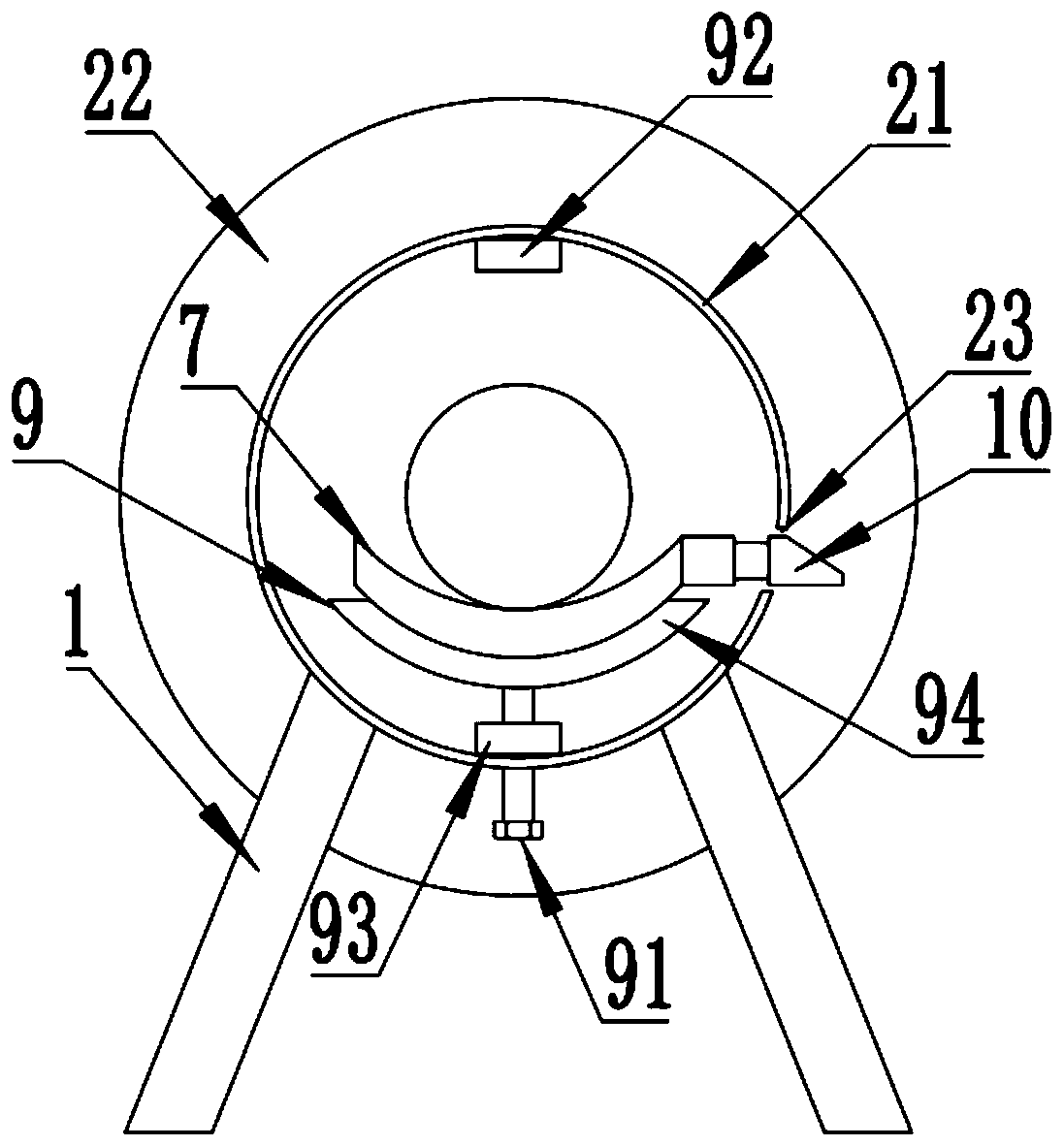

[0031] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to specific embodiments and drawings.

[0032] It should be noted that all the expressions "first" and "second" in the embodiments of the present invention are used to distinguish two entities with the same name but not the same or parameters that are not the same, as shown in "first" and "second" Only for the convenience of presentation, it should not be construed as a limitation to the embodiments of the present invention, and subsequent embodiments will not describe this one by one.

[0033] A cable eccentricity detection device, such as Figure 1 to Figure 3 As shown, the bracket 1 is included. The ball screw 2 includes a screw 21 and a nut 22. Both ends of the screw 21 are fixedly erected on the bracket 1. The screw 21 is a hollow structure. The side wall of the screw 21 is provided with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com