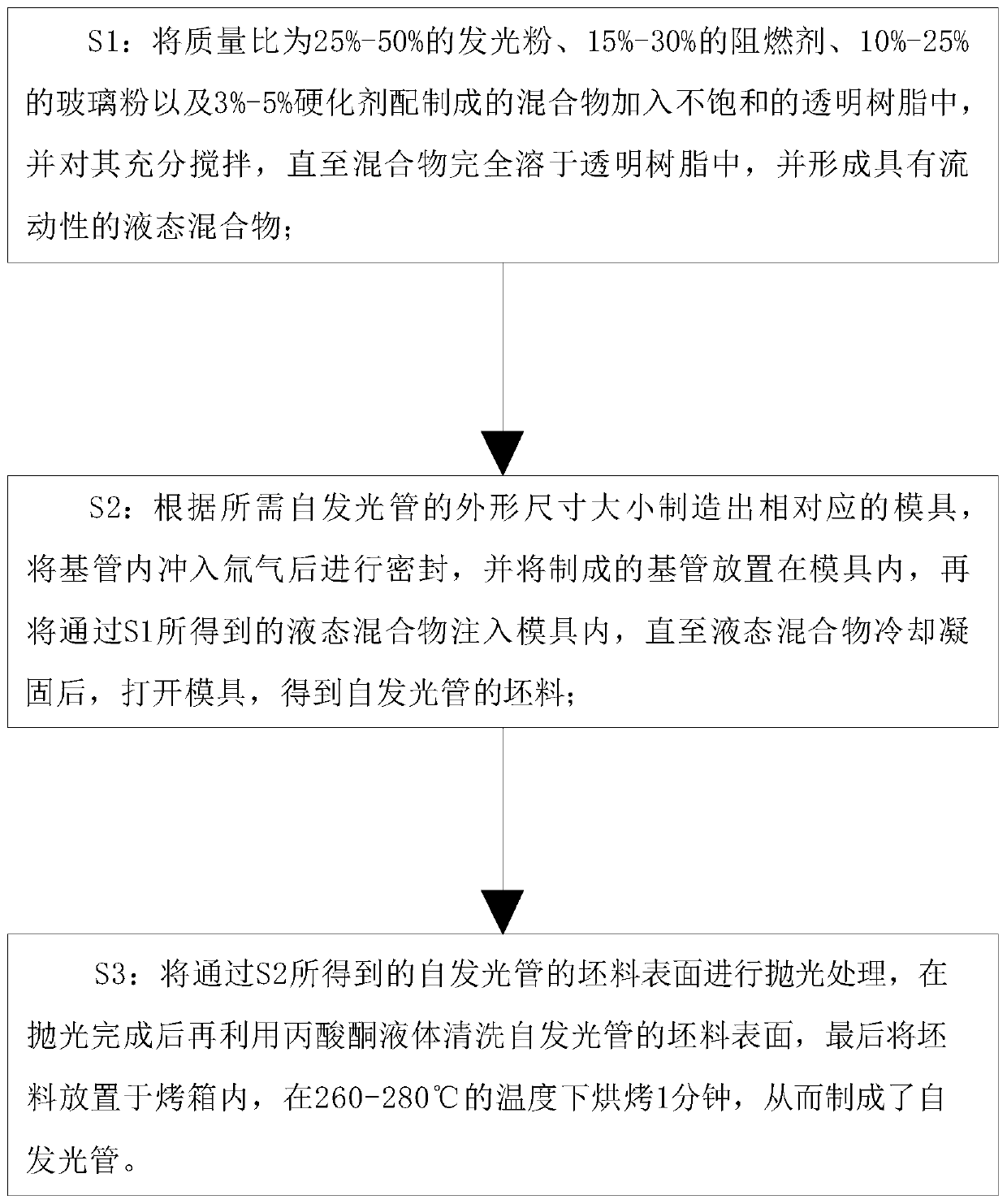

Self-luminous tube and manufacturing method thereof

A manufacturing method and self-luminous technology, applied in the direction of fluorescence, light source, light source fixation, etc., can solve the problems of limited lighting range, weak light, limited use effect of self-luminous tube, etc., to enhance the use effect and use range, and avoid accumulation. , the effect of extending the light distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

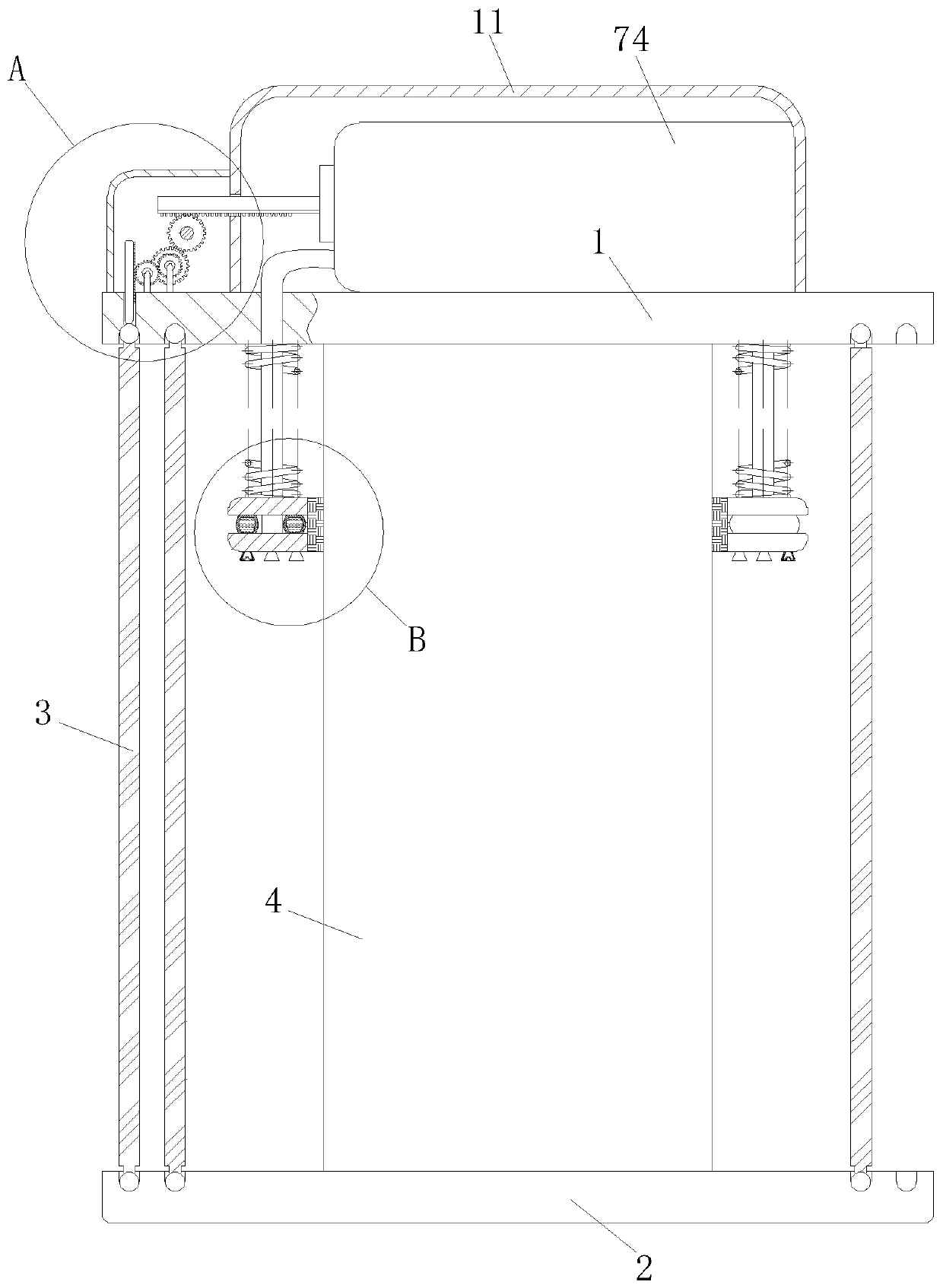

[0028] As an embodiment of the present invention, the top plate 1 is provided with a housing 11, and the top plate 1 has a through hole 12 near the housing 11, so that the through hole 12 communicates with the annular outer chute 6; A cleaning unit 7 is provided in the body 11; the cleaning unit 7 includes a No. 1 rack 71, a gear set 72, a push rod 73 and an air bag 74; the No. 1 rack 71 is slidably connected in the through hole 12; the gear The group 72 is installed on the inner side wall of the housing 11 and meshes with the No. 1 rack 71; the push rod 73 is slidably connected in the housing 11, and the side wall of the push rod 73 is provided with a No. 2 rack 731, so that the two The number rack 731 is meshed with the gear set 72; the airbag 74 is installed in the housing 11, and the side wall of the airbag 74 is always in contact with the end of the push rod 73; the lamp tube 4 is fitted with a ring-shaped cleaning brush 75 through a spring ; The annular cleaning brush 75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com