Two-shaft two-frame mechanism with ball head connecting rod transmission mechanism

A technology of transmission mechanism and ball joint rod, which is applied in the direction of machine/bracket, pivot connection, supporting machine, etc. It can solve the problems affecting the performance index of photoelectric equipment and restricting the angular rotation range of the frame, so as to increase the weight of the lower part and reduce the weight of the frame. The effect of upper weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

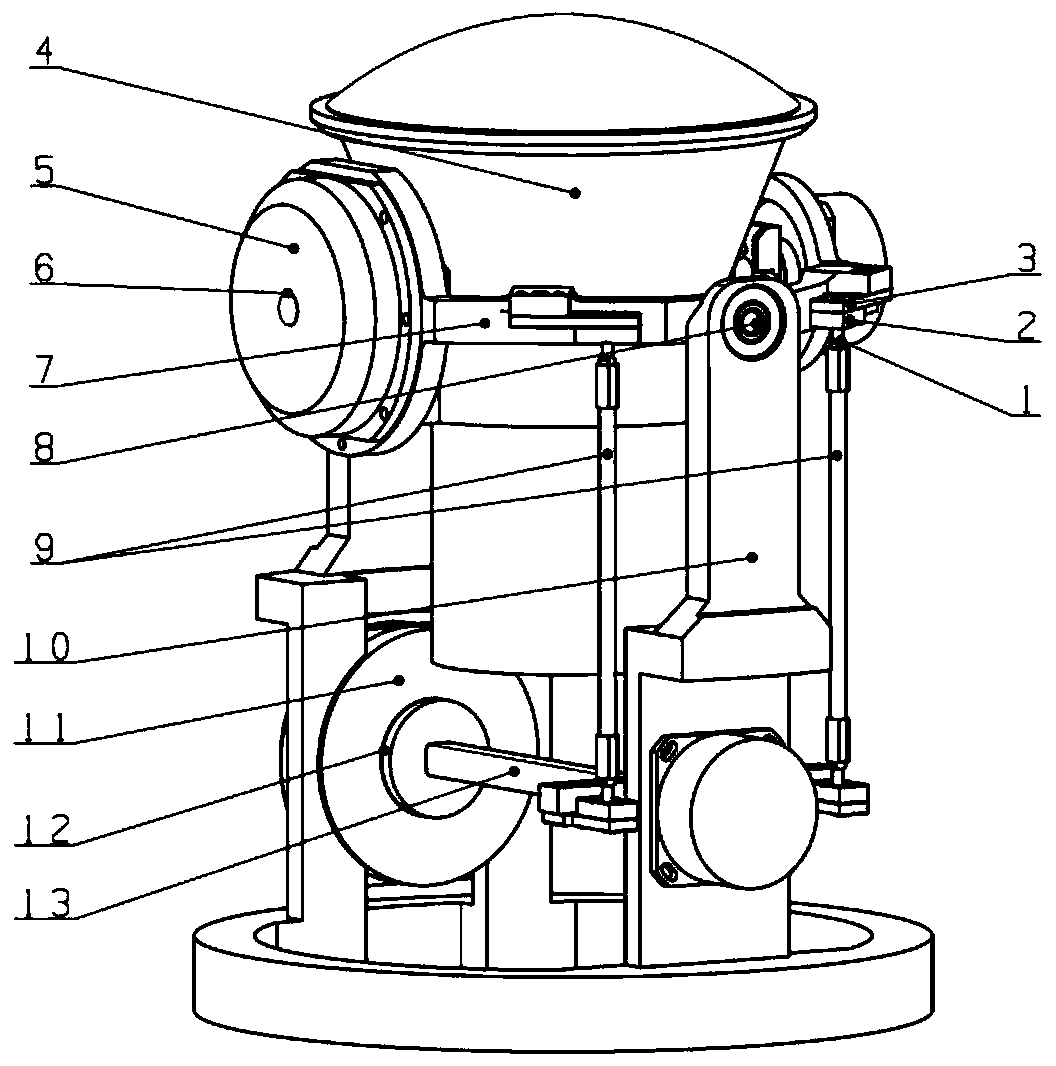

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

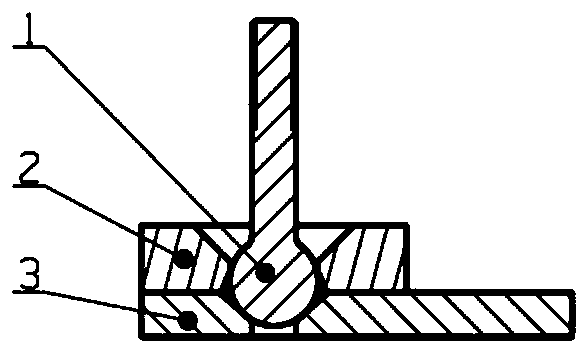

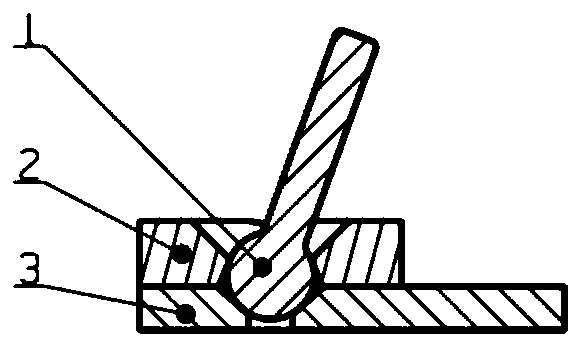

[0029] Please also see figure 1 , figure 2 , image 3 and Figure 4 .

[0030] The two-axis two-frame mechanism with a ball-joint link transmission mechanism in this embodiment includes a platform 4, a pitch motor 5, a pitch shaft system 6, a pitch bracket 7, an azimuth motor 11, an azimuth shaft system 12, an azimuth bearing component 8, The azimuth bracket 10, the azimuth shafting connecting rod 13 and the ball joint transmission mechanism.

[0031] The platform 4 is arranged on the pitch axis system 6, and the pitch axis system is arranged on the pitch bracket 7; the pitch motor 5 can drive the platform (4) to rotate in the pitch direction through the pitch axis system 6 .

[0032] The pitch bracket 7 is arranged on the azimuth bearing part 8, and the axis of the azimuth bearing part 8 is perpendicular to the axis of the pitch shaft sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com