Large-section soft ground tunnel full-section construction structure and construction method

A technology with weak strata and large cross-sections, which is applied in tunnels, tunnel linings, underground chambers, etc., and can solve the problems of poor versatility, uneconomical equipment, and many excavation sections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

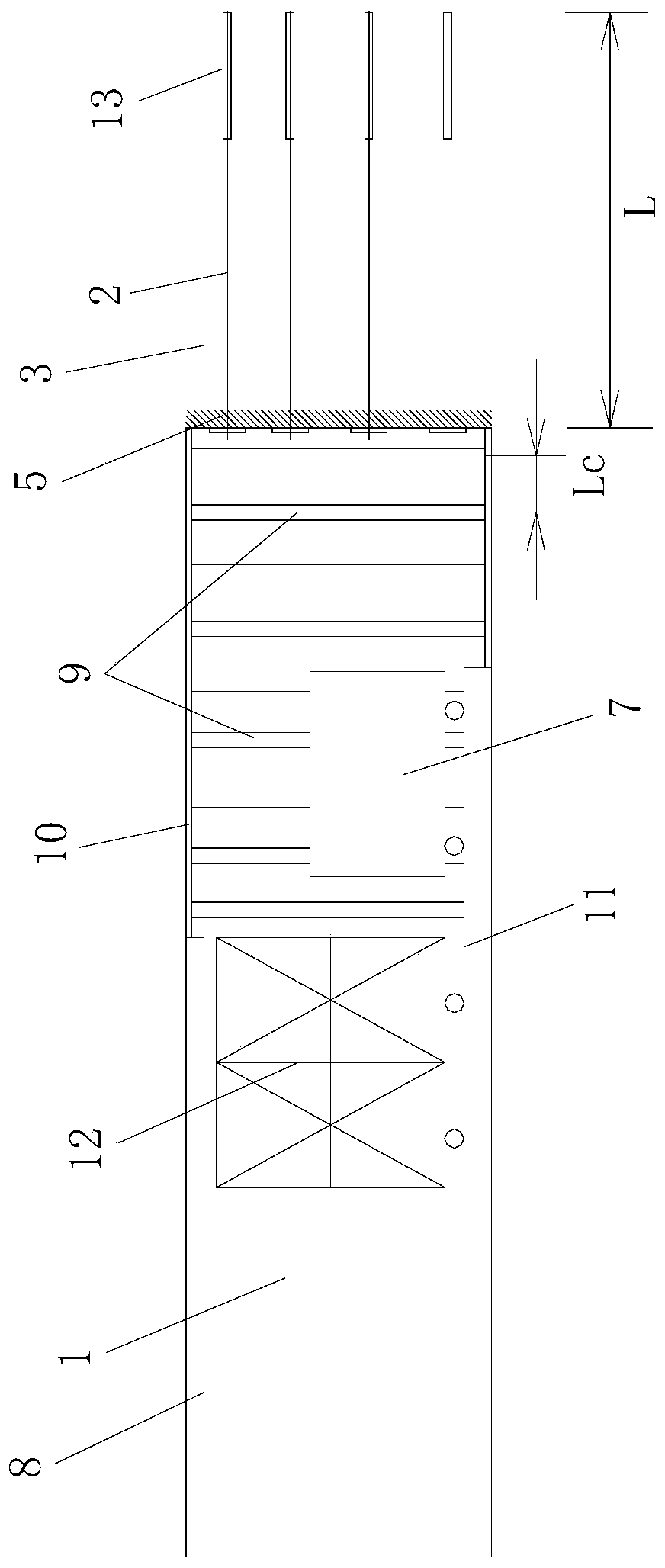

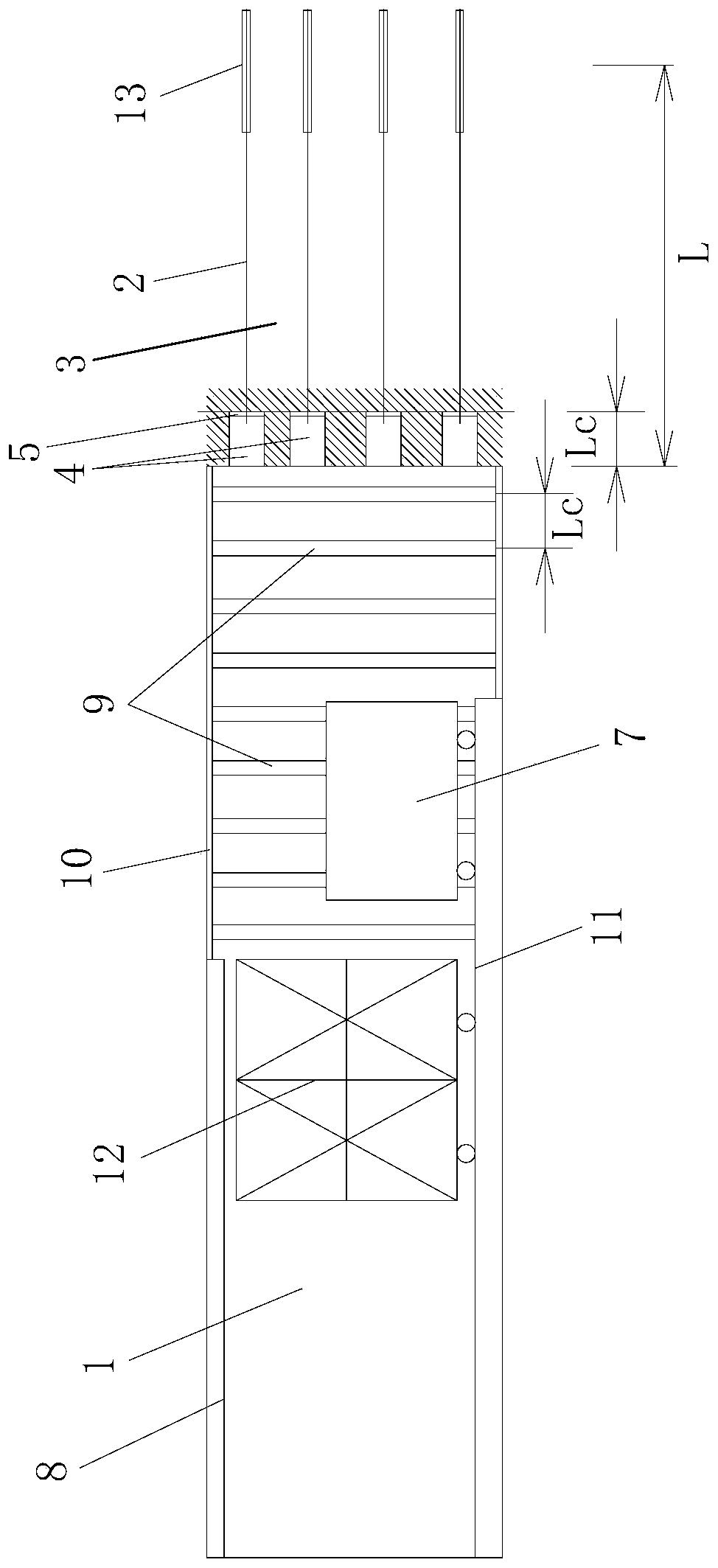

[0075] Such as figure 1 , figure 2 The full-section construction structure of a large-section soft ground tunnel shown includes a tunnel excavation and anchorage system for excavating and anchoring the rock mass 3 in front of the face of the tunnel to be constructed, and the tunnel to be constructed has an excavation section greater than 50m 2 Large-section soft rock tunnel or large-section loess tunnel; the tunnel excavation and anchoring system includes a plurality of tunnel excavation and anchoring mechanisms for excavating and anchoring the rock mass 3 in front of the tunnel face; The structures of the excavating and anchoring mechanisms are the same and they are located in front of the face of the constructed tunnel, and a plurality of said tunnel excavating and anchoring mechanisms are arranged in parallel and arranged along the tunnel longitudinal extension direction of the constructed tunnel;

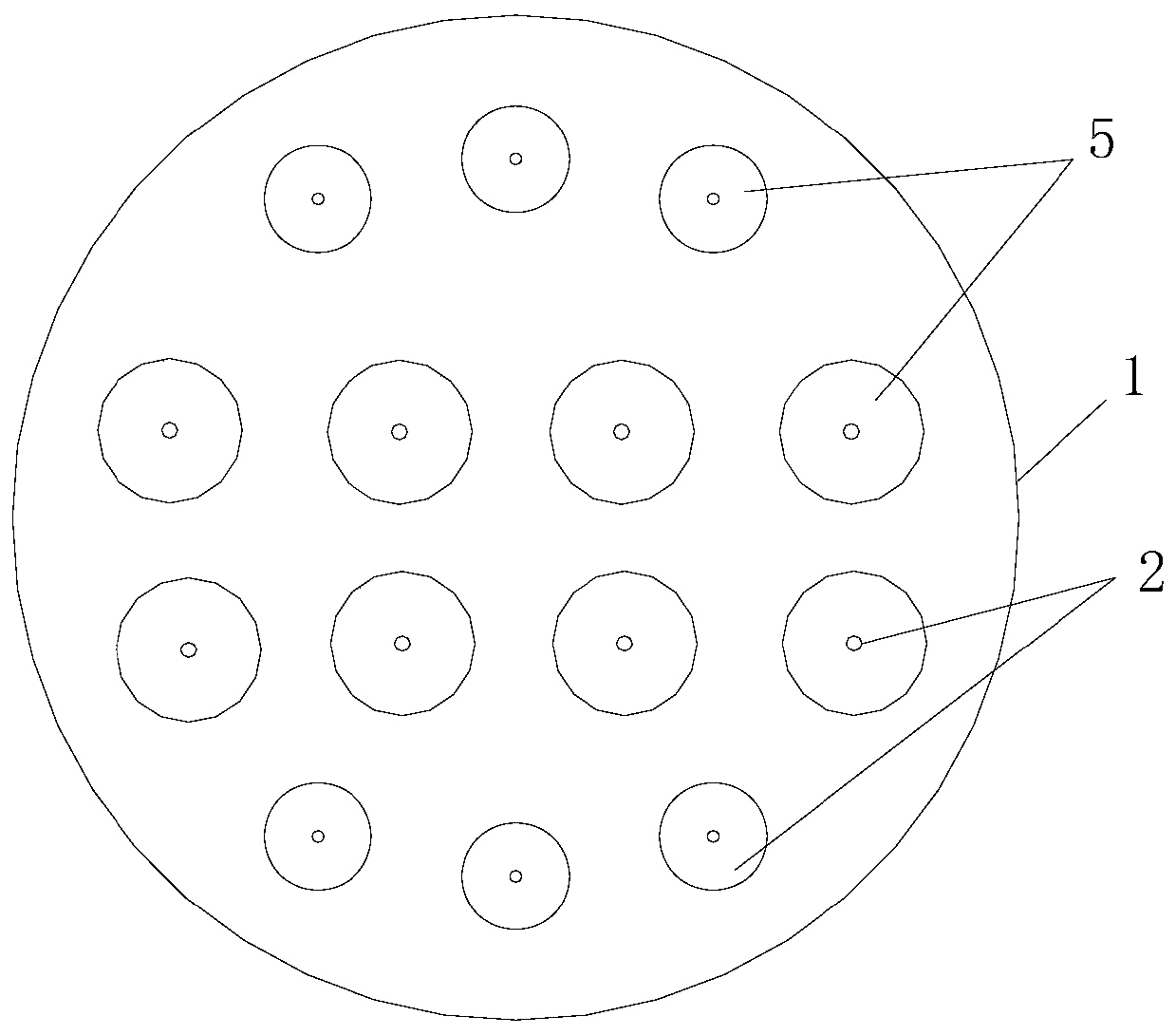

[0076] combine image 3 Each of the tunnel excavation and anchoring mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com