Ultraviolet curing paint for sealing pine turpentine and preparation method thereof

A technology for curing coatings and turpentine, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as unsatisfactory sealing effect and inability to seal turpentine well, achieve good and lasting sealing effect, reduce Risk of delamination and peeling of paint film, effect of improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] On the other hand, the embodiment of the present invention also provides a kind of preparation method that is used for sealing the ultraviolet curing coating of pine turpentine, comprises the following steps:

[0031] S01, each component is weighed according to the formula of the UV-curable coating of pine wood turpentine described in the embodiment of the present invention;

[0032] S02, subjecting the water-soluble UV resin, polyester acrylate resin, polyurethane acrylate, wetting agent, defoamer and leveling agent to a first mixing treatment to obtain a first mixing product;

[0033] S03. Add the photoinitiator and active monomer into the first mixture, and perform a second mixture treatment to obtain the UV-curable coating of sealed pine turpentine.

[0034] The preparation method of the UV-curable coating for sealing pine wood turpentine provided by the embodiment of the present invention has the characteristics of simple process, low cost and high efficiency; when...

Embodiment 1

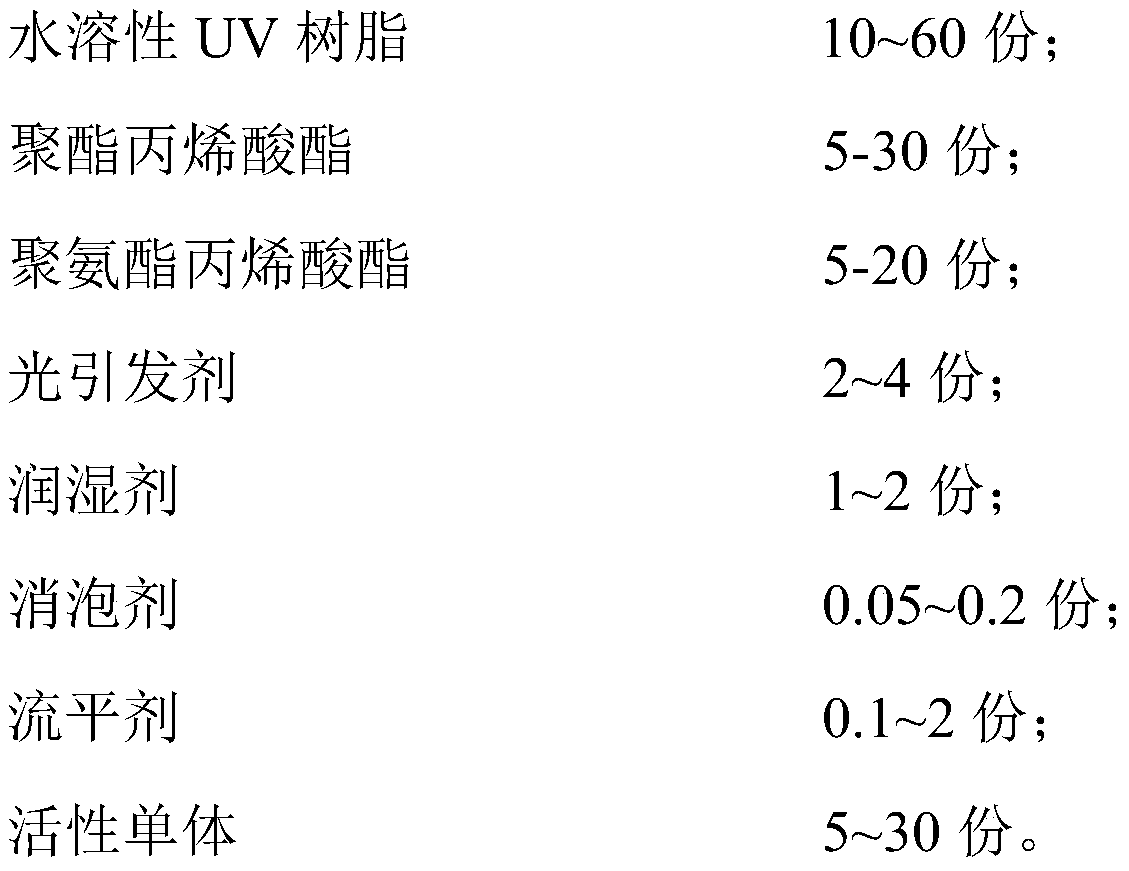

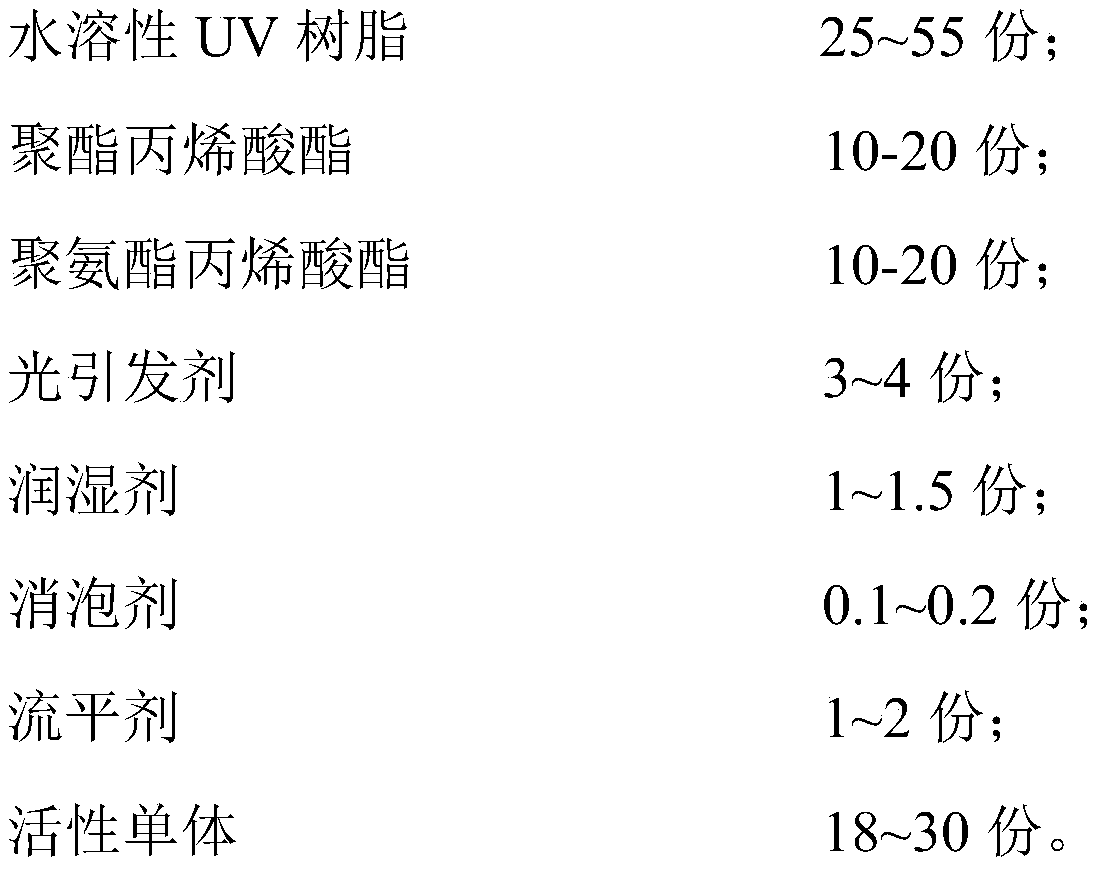

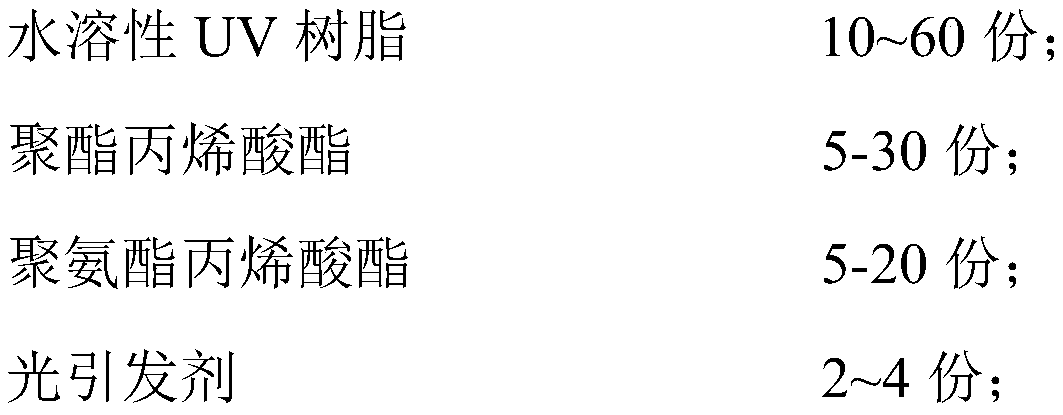

[0038] The content of each component by weight of the UV-curable coating provided in this embodiment is shown in Table 1:

[0039] Table 1

[0040]

[0041]

[0042] In the above table 1, the polyester acrylate resin is Boxing Chemical B522; the wetting agent is BYK-190; the defoamer is non-silicon defoamer Tego-920; the leveling agent is BYK-358N; It is Ciba's trademark 1173; the active monomer is Cytec's polyacrylic acid monomer.

[0043] The preparation method of the UV-curable coating provided in this embodiment is as follows:

[0044] S11: Weigh the raw materials of each component according to the components contained in the UV-curable coating in the above Table 1 and their parts by weight;

[0045] S12: Stir the above-mentioned water-soluble UV resin, polyester acrylate resin, polyurethane acrylate, wetting agent, defoamer, and leveling agent at a temperature below 50°C and a speed of 800-1000 rpm for 10-15 minutes.

[0046] S13: Then add photoinitiator and some...

Embodiment 2

[0054] The content of each component of the UV-curable coating provided in this embodiment is shown in Table 3 (in parts by weight).

[0055] table 3

[0056] Component parts by weight Water-soluble UV resin 35.0 copies Polyester acrylate resin 20.0 copies urethane acrylate 15.0 copies Defoamer 0.1 part D 1.5 servings leveling agent 1.0 copies Photoinitiator 3.0 copies active monomer 24.4 copies

[0057] In the above table 3, the polyester acrylate resin is Boxing Chemical’s B522; the wetting agent is Rohm and Haas’ water-based paint wetting and dispersing agent; 358N; the photoinitiator is Ciba company brand 1173; the active monomer is the polyacrylic acid monomer of Cytec. The preparation method of the UV-curable coating provided in this embodiment is basically the same as that in Embodiment 1, and will not be repeated here.

[0058] The above-mentioned UV-curable coating is sprayed on the surface of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com