Sewage treatment device for environmental engineering

A technology of sewage treatment equipment and environmental engineering, applied in water/sewage treatment, heating water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of filter plate clogging and low filtration efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

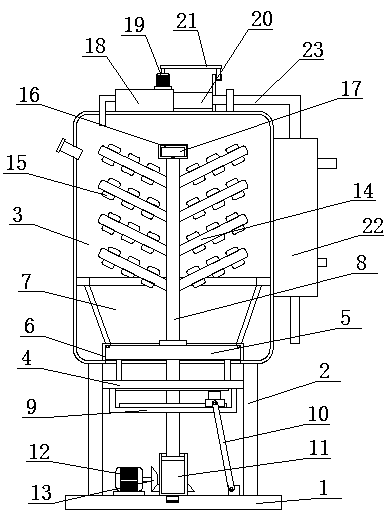

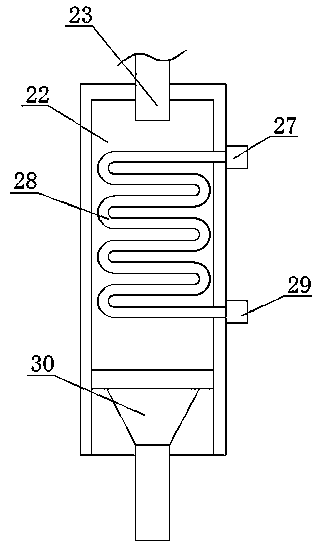

[0032] see Figure 1-5 , this embodiment provides a sewage treatment device for environmental engineering, including a base 1, two uprights 2 are symmetrically fixedly installed on the top of the base 1, and the same evaporation box 3 is fixedly installed on the top of the two uprights 2, two The sides of the columns 2 close to each other are slidably connected with the same moving plate 4, the top of the moving plate 4 is fixedly equipped with a sealing plate 5, the bottom inner wall of the evaporation box 3 is fixedly installed with a sealing ring 6, and the bottom inner wall of the evaporation box 3 is provided with a There is a moving hole, the top of the sealing plate 5 extends into the sealing ring 6 and seals with the inner wall of the sealing ring 6, the sealing plate 5 is rotatably connected with a rotating shaft 8, and the bottom end of the rotating shaft 8 extends to the bottom of the moving plate 4, and the rotating shaft 8 is equipped with a stirring mechanism, th...

Embodiment 2

[0036] see Figure 1-5 , further improvements have been made on the basis of Example 1:

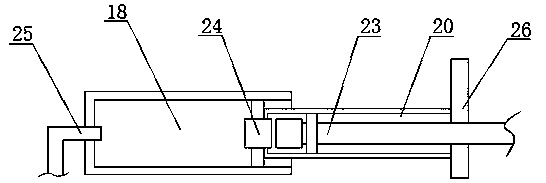

[0037] In this embodiment, a mounting plate 9 is fixedly mounted on one side of the bottom of the moving plate 4, and a slide plate 31 is slidably connected to the top of the mounting plate 9, and a brake motor 32 is fixedly mounted on the top of the slide plate 31. The output shaft of the brake motor 32 A transmission gear 33 is fixedly installed on the top, and a transmission rack 34 is fixedly installed on the bottom of the moving plate 4. The transmission gear 33 is meshed with the transmission rack 34. One side of the slide plate 31 is rotatably connected with a support rod 10, and one end of the support rod 10 is connected to the One side of the top of the base 1 is rotationally connected, and the support rod 8 can be driven to rotate by using the brake motor 32, the transmission gear 33 and the transmission rack 34.

[0038] In this embodiment, the stirring mechanism includes a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com