Sorting and conveying device for tile films

A technology of conveying device and arranging device, which is applied in the directions of transportation and packaging, packaging, packaging protection, etc., can solve the problems of inconvenient and neat packaging, inconvenient packaging, etc., and achieve the effect of convenient operation, simple structure and reduction of manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

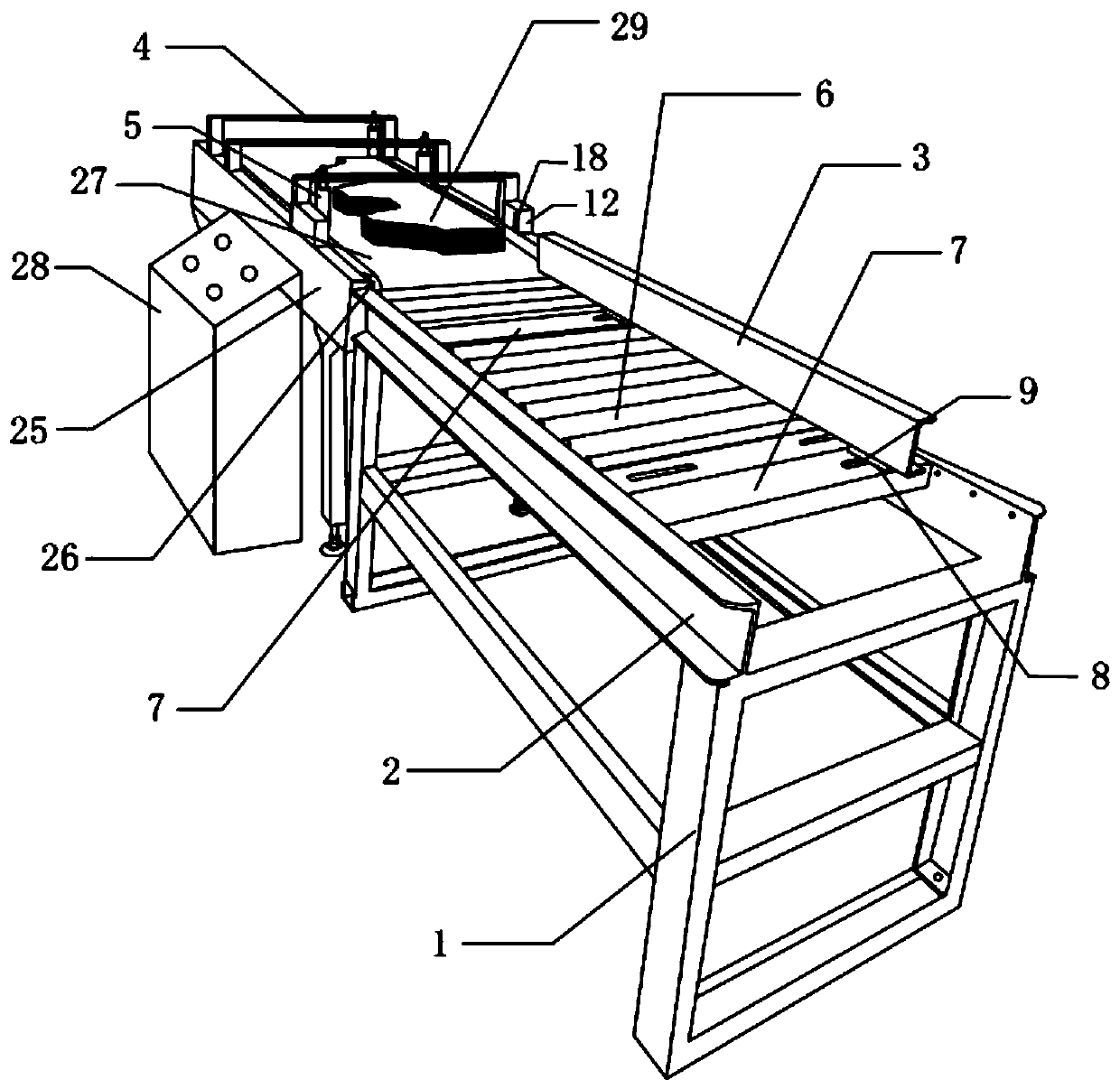

[0038] refer to figure 1 , Figure 4 , Figure 5 with Image 6 As shown, a sorting and conveying platform for strip-shaped tile film 10 in this embodiment 1 includes a conveying device and a controller 28, and a finishing device is provided on the side of the inlet of the conveying device; the finishing device includes a finishing device Frame 1, a finishing table arranged on the finishing frame 1 and side panels 2 arranged on both sides of the finishing table, the finishing frame 1 includes a plurality of interconnected brackets, and the cross-section of each bracket is "concave" shape, thereby reducing the need for finishing. The overall weight of the frame 1 is convenient for transportation. The brackets on both sides are welded to form a support frame, and a bracket is welded in the middle of the support frame, which improves the stability of the finishing frame 1. The brackets between the support frames are detachably connected. It occupies a small area and can be eas...

Embodiment 2

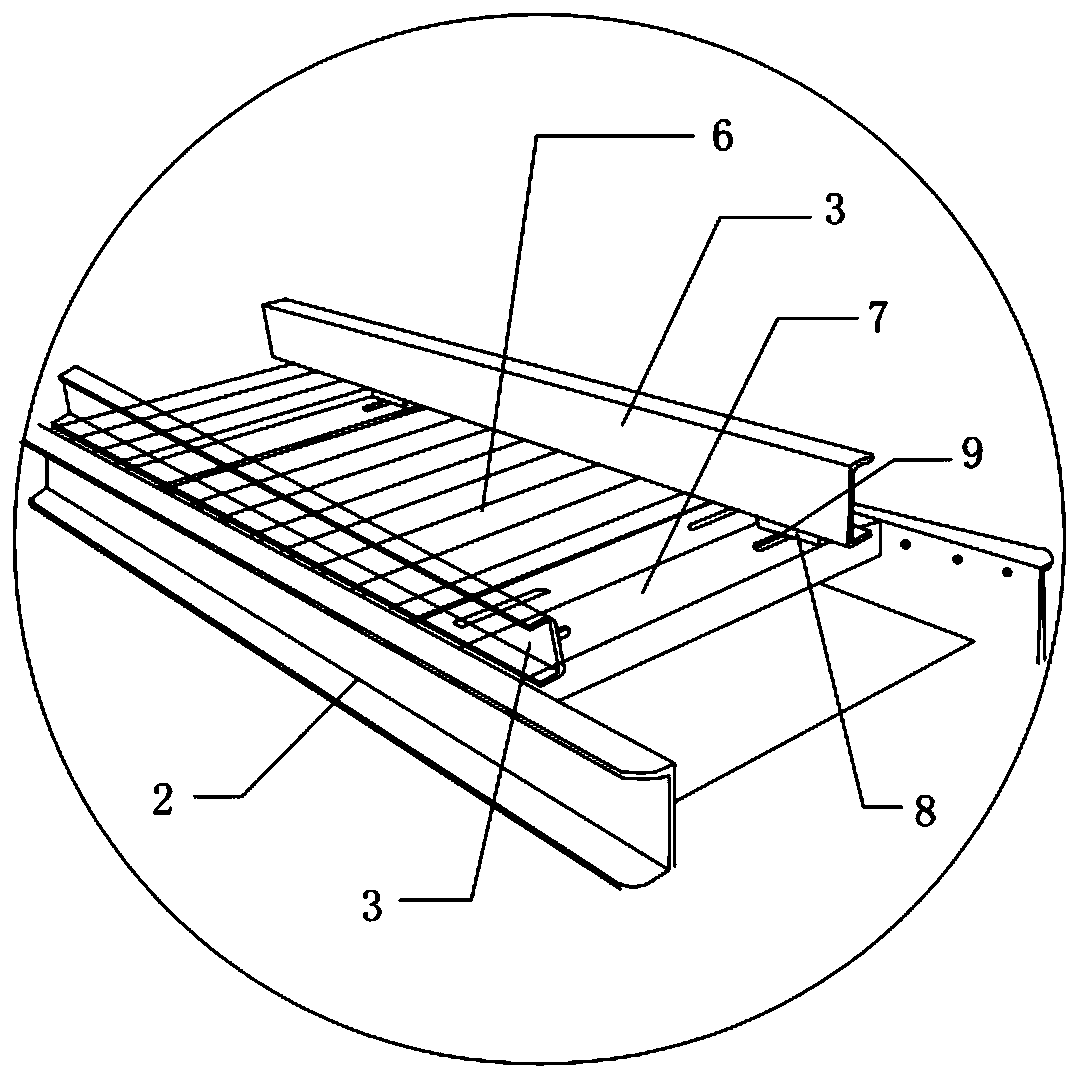

[0043] refer to figure 2 with image 3 As shown, the difference from Embodiment 1 is that the roller 6 is set as a shaft-driven roller 6, and the roller 6 includes a rolling shaft 19 pierced through the side plate 2, and a cylinder 20 sleeved on the rolling shaft 19. The rotating motor 21 connected with the rolling shaft 19 is provided with a switch sensor, and the input end of the switch sensor is connected with the output end of the controller 28 . Described baffle plate 3 comprises two that are arranged symmetrically in parallel, and two baffle plates 3 are all arranged on the left and right sides of arranging table, and the lower end of two baffle plates 3 is provided with slide block 8, cooperates slide block 8 on the stop bar 7 The first slide rail 9 is provided, and the first slide rail 9 is also symmetrically arranged on the left and right sides of the limit rod 7. The slide block 8 is provided with a first moving mechanism, and the first moving mechanism includes a ...

Embodiment 3

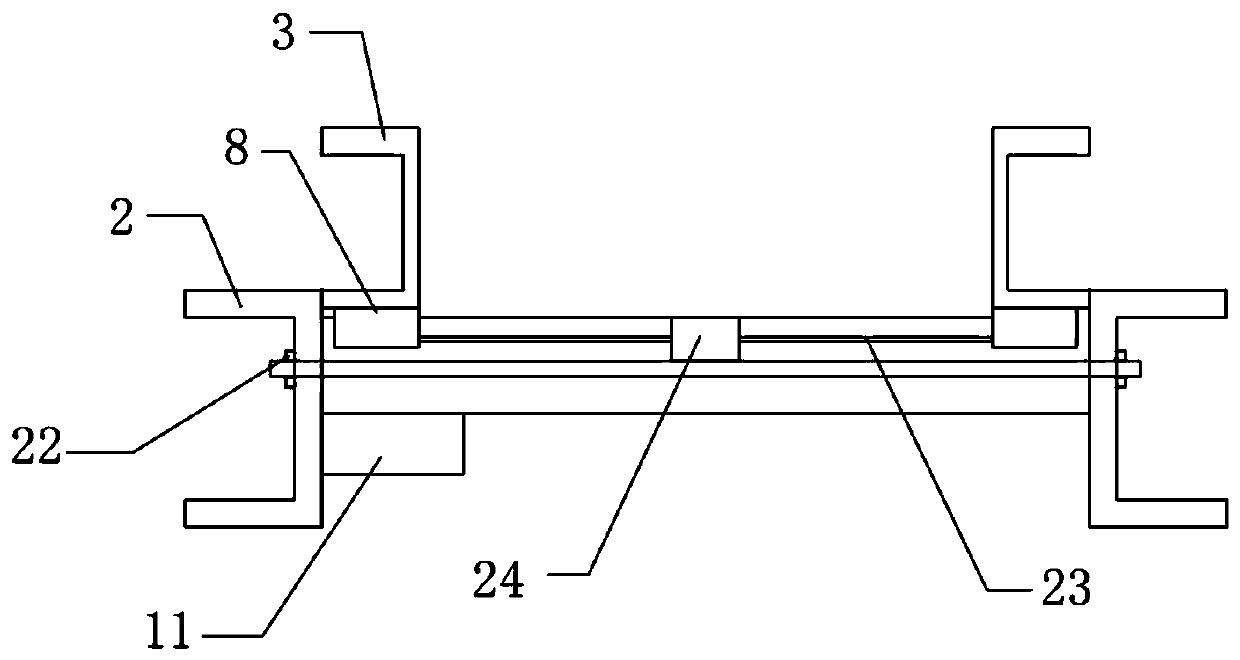

[0046] refer to image 3 As shown, the difference from Embodiment 3 is that: the limit rod 7 is provided with a pressure sensing device 11 , and the output end of the pressure sensor is connected to the input end of the controller 28 .

[0047] By adopting the above-mentioned technical scheme, the overlapping strip-shaped tile film 10 is placed between the two baffles 3 of the finishing table, the pressure sensing device 11 detects the weight signal, and transmits the weight signal to the controller 28, and the controller 28 After receiving the signal, the opening signal is transmitted to the first moving mechanism. After the first moving mechanism receives the signal, it drives the slider 8 to move, and then the two baffles 3 move inward at the same time, and the strip-shaped tile film 10 is moved up and down. Both sides are aligned. After alignment, the controller 28 turns on the roller 6 to rotate, and the rolling roller 6 strip-shaped tile film 10 is pushed forward, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com