Offshore wind power operation and maintenance ship embarking device and embarking method thereof

An offshore wind power, operation and maintenance technology, applied in ship cleaning devices, transportation and packaging, hull and other directions, can solve the problems of low operation and maintenance efficiency, lack of operation and maintenance management experience, high safety risks, etc., to improve safety and efficiency, Simplify the login process and avoid dangerous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

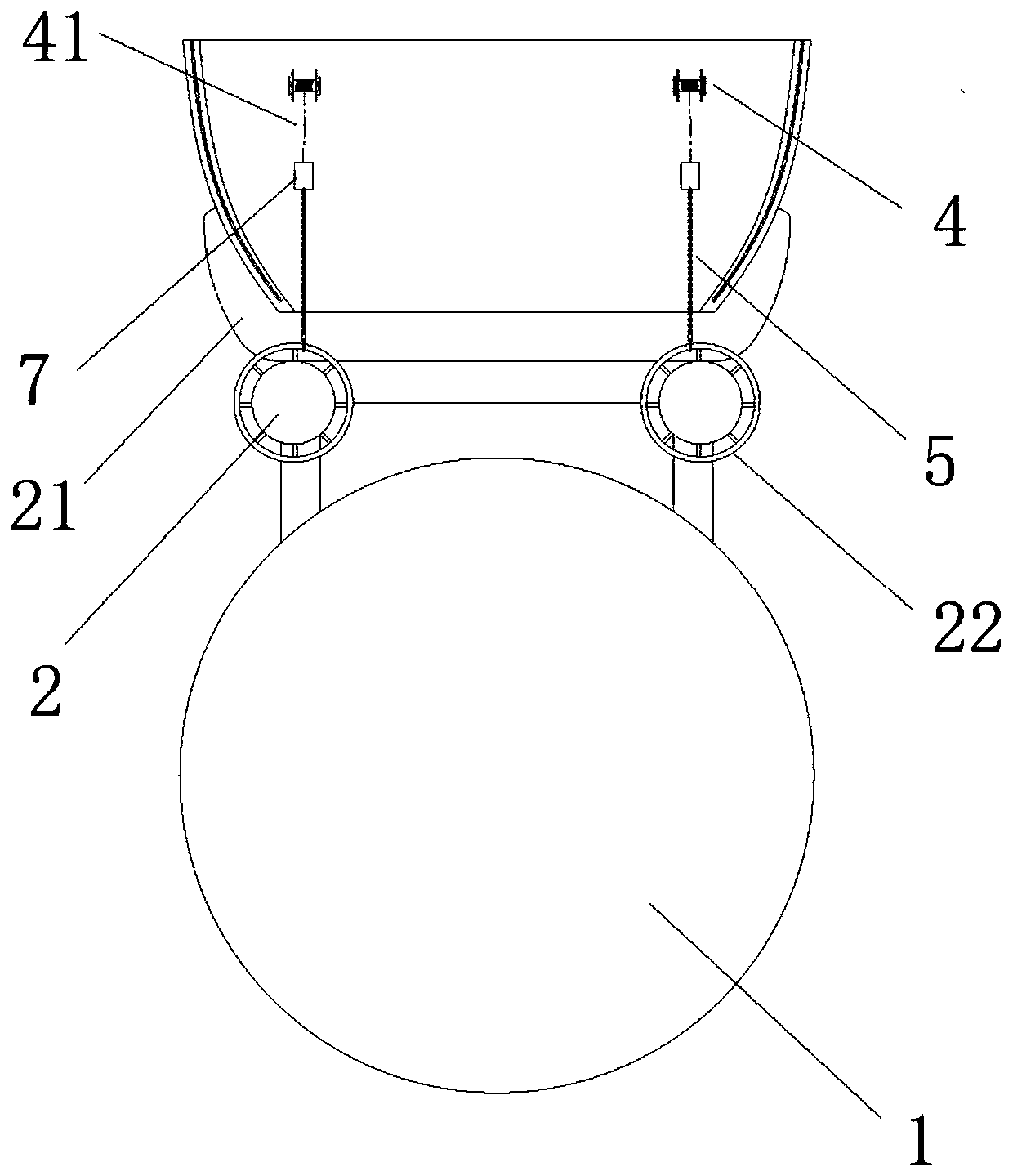

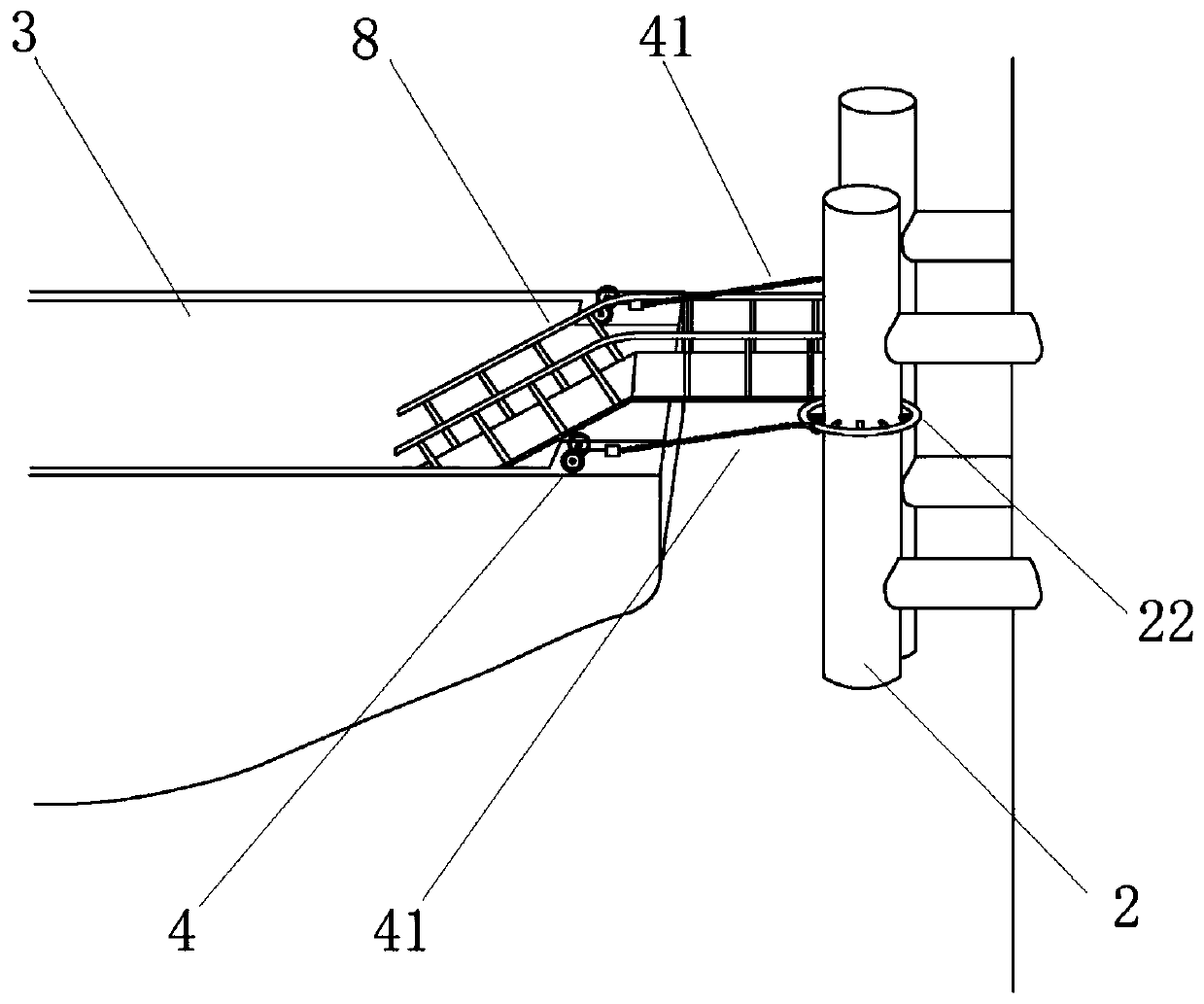

[0027] Such as Figure 1-4 As shown, a boarding device for an offshore wind power operation and maintenance ship includes an anti-collision mechanism. The anti-collision mechanism includes two holding piles 2 located in front of the wind power pile 1, and ship fenders 21 are arranged between the holding piles to prevent transportation. The bow of the maintenance ship is damaged when boarding; each pile 2 is also provided with a pile fastening ring 22, and the pile fastening ring 22 is used to cooperate with the fixed operation and maintenance ship 3.

[0028] The berthing mechanism includes a pair of drum winches 4, and the drum winches 4 are arranged on both sides of the bow of the operation and maintenance ship 3. Each drum winch 4 is wound with a rope 41, and the rope 41 is wound from each drum. Each drum winch 4 is extended or retracted to each drum winch 4, which is used to control the distance between the bow of the operation and maintenance ship 3 and the pile 2;

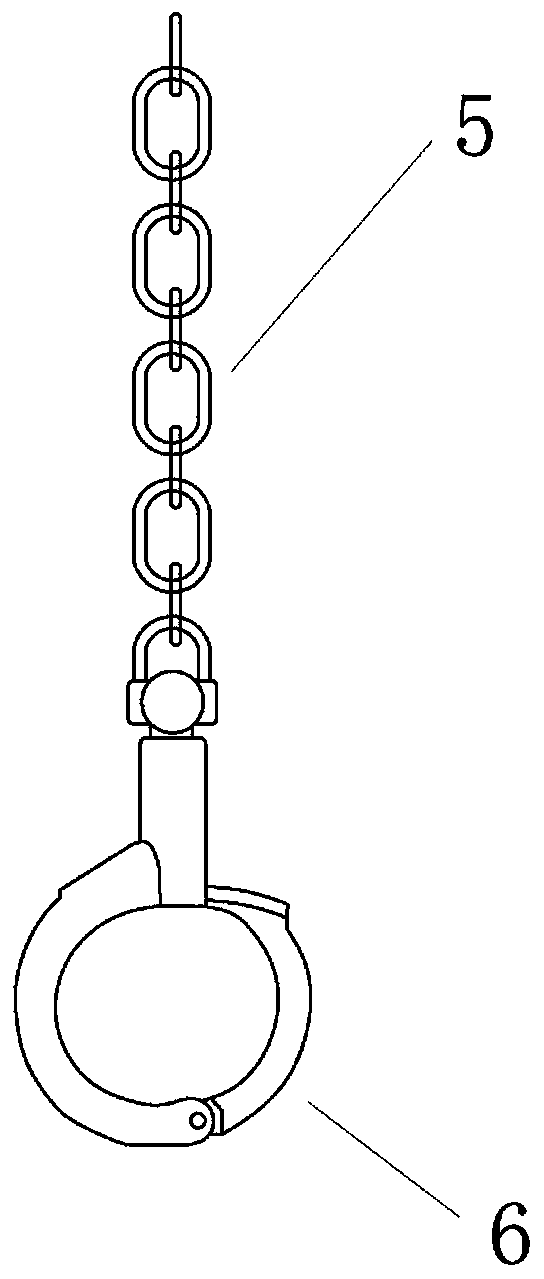

[00...

Embodiment 2

[0038] The chain stop is a screw type chain stop, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com