Super-capacitor energy storage system for vehicle, rail vehicle and cooling method of super-capacitor energy storage system for vehicle

An energy storage system and super capacitor technology, applied in the field of rail vehicles, can solve the problems of complex docking structure between the carriage and the energy storage system, and the upper and lower super capacitor modules cannot achieve the same cooling effect, and achieve the effect of simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

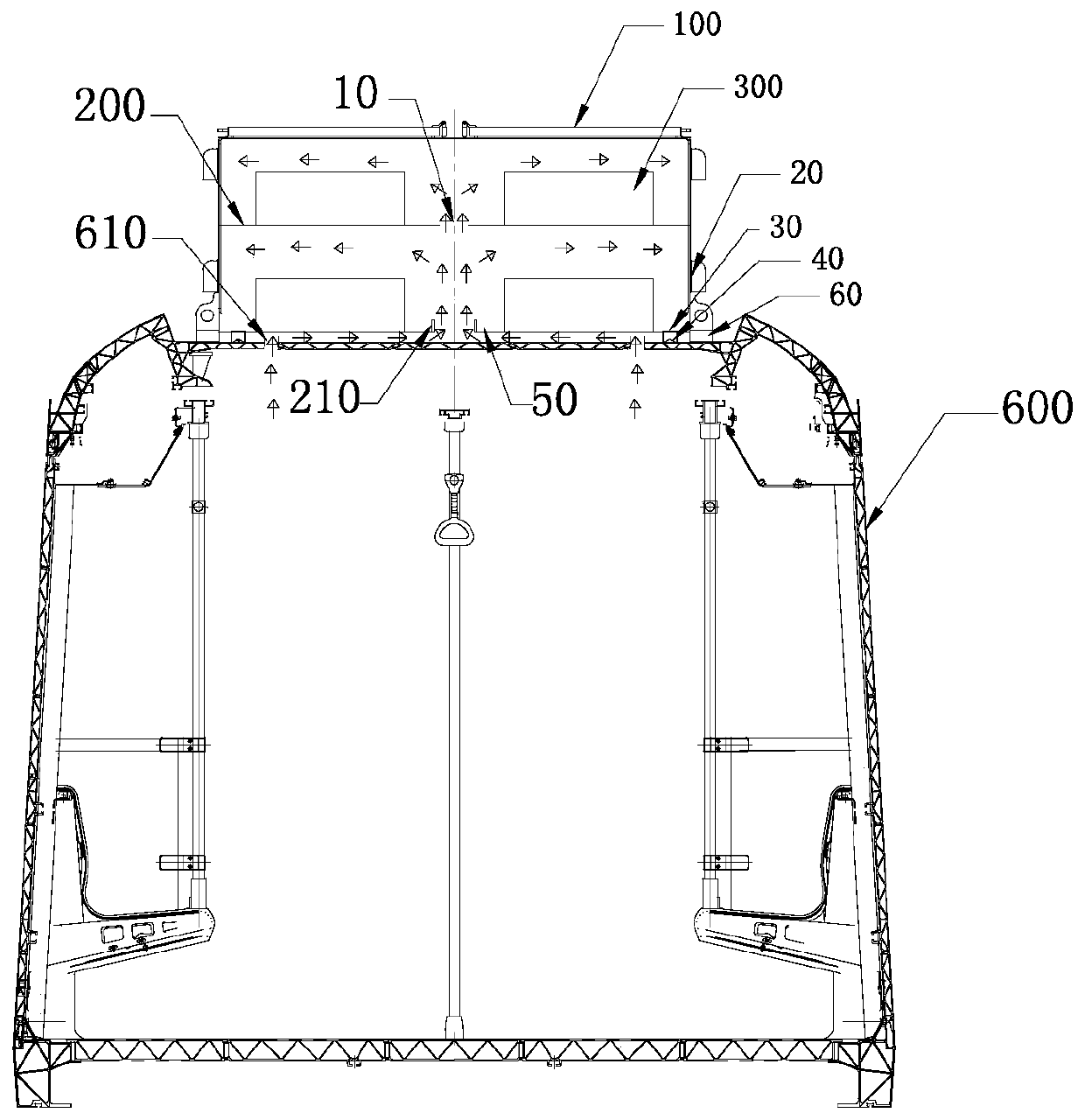

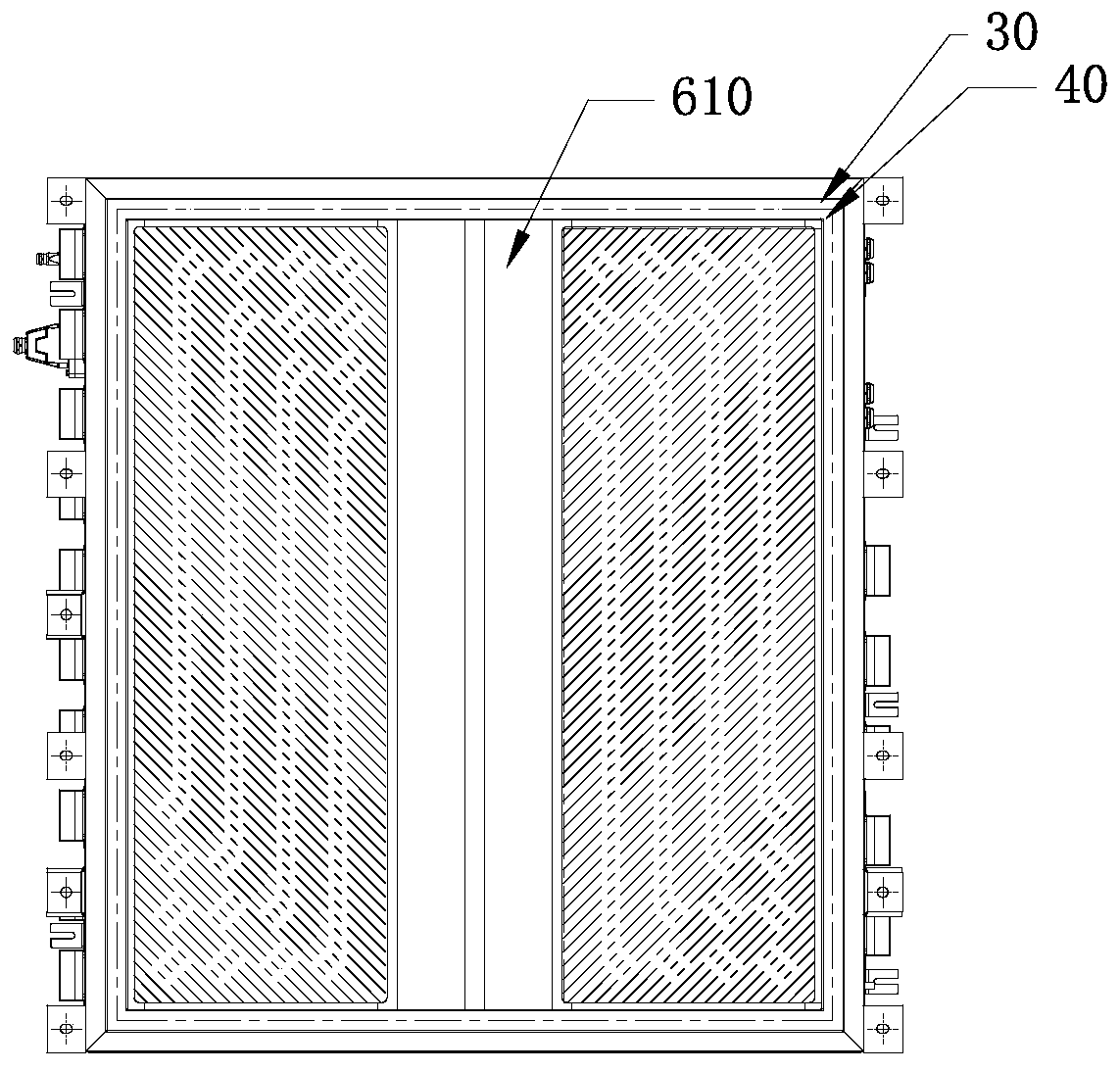

[0031] A supercapacitor energy storage system for a vehicle, comprising an energy storage cabinet 100, a plurality of slave control detection units 400, a master control unit 500, a plurality of mounting plates 200 arranged in the energy storage cabinet 100 and mounted on the installation A plurality of supercapacitor modules 300 on the board 200; the middle part of the energy storage cabinet 100 is provided with an air duct 10 connected with the interior of the energy storage cabinet 100, and the air duct 10 separates the plurality of installation plates 200 into There are two groups on the left and right, and the mounting plates 200 in each group are arranged up and down; the left and right sides of the energy storage cabinet 100 are respectively provided with a plurality of fans, and the bottom of the energy storage cabinet 100 protrudes from the bottom of the energy storage cabinet 100 with a sealing groove 30 in a circle , the seal groove 30 is provided with a seal gasket ...

Embodiment 2

[0048] A rail vehicle includes an energy storage system and a carriage 600; the energy storage system is located on the top of the carriage 600, and the carriage 600 directly supports the energy storage system.

[0049] The top of the compartment 600 is provided with an air outlet 610 ; the energy storage system is covered on the air outlet 610 of the compartment 600 , specifically by utilizing the wind discharged from the compartment 600 to cool the energy storage system.

[0050] The top of the compartment 600 is in contact with the sealing groove 30 in the energy storage cabinet 100 and forms a cavity with the bottom layer of the energy storage cabinet 100 , and the cavity communicates with the air outlet 610 and the air duct 10 at the same time.

[0051] In this embodiment, the bottom layer of the energy storage cabinet 100 specifically includes two mounting plates 200, wherein the sealing groove 30 protrudes from the bottom layer of the energy storage cabinet 100, and the ...

Embodiment 3

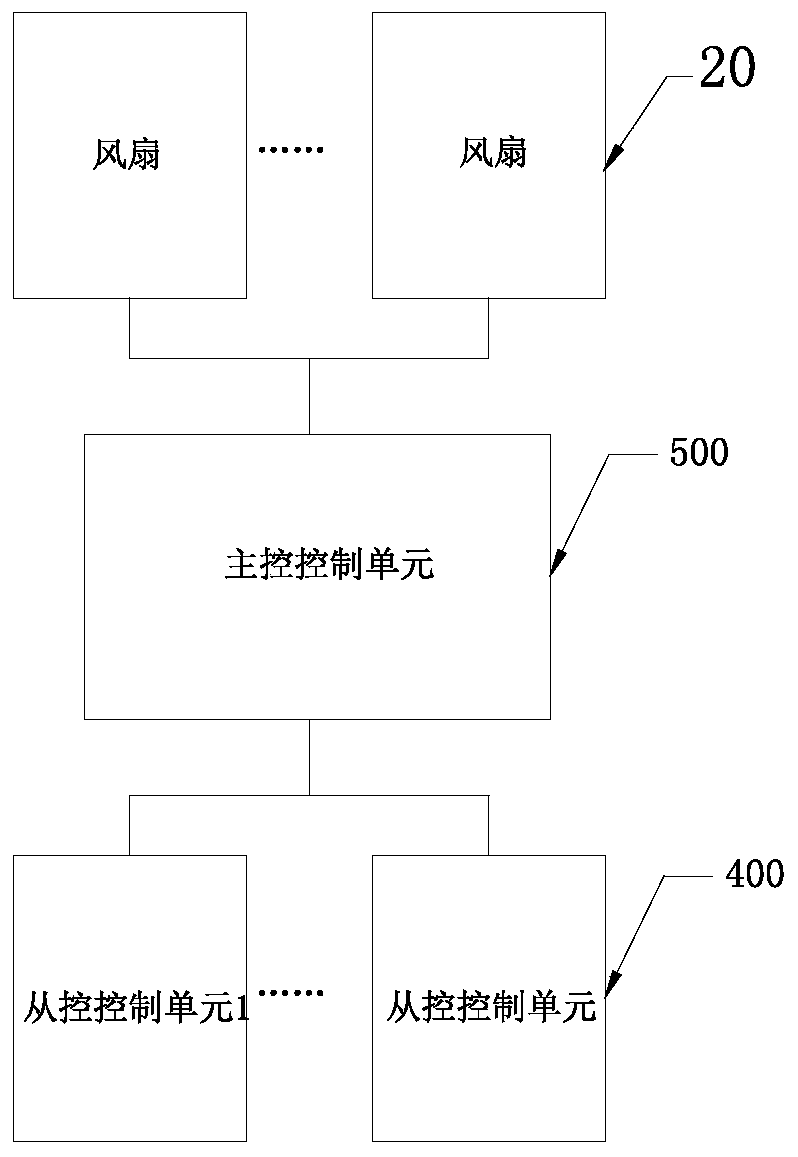

[0057] A cooling control method for a supercapacitor energy storage system for a vehicle, comprising the following steps:

[0058] S1, detecting the temperature of the supercapacitor module 300 through the slave control unit and sending it to the master control unit 500 in real time;

[0059] S2, judging the temperature of the supercapacitor module 300, and controlling the number of fans corresponding to the temperature in the supercapacitor module 300;

[0060] S3, when the temperature is still rising after the preset fan is turned on, the main control unit 500 controls to continue to increase the number of fans until the temperature is maintained within the preset range. If the temperature exceeds the preset range, the The main control unit 500 controls the circuit breaker to open.

[0061] When the supercapacitor module 300 is powered, it is easy to generate heat. In this embodiment, the temperature of the supercapacitor module 300 is monitored by the slave control unit, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com