Corrugated interface bimetal composite plate forming method

A forming method and composite board technology, applied in the direction of chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of affecting aesthetics and wasting raw materials, so as to achieve more firm bonding and facilitate continuous control of output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

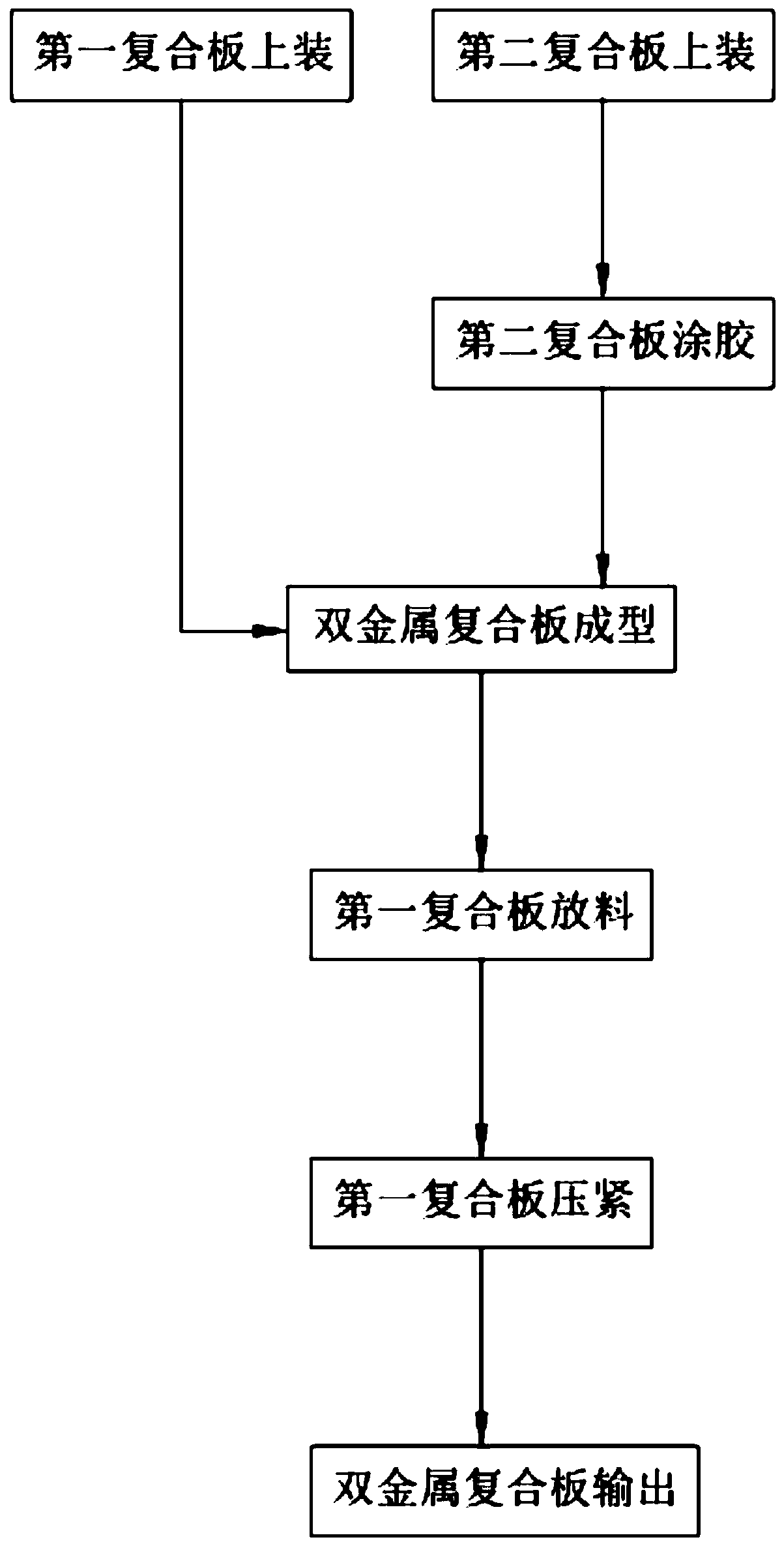

[0073] like figure 1 As shown, a corrugated interface bimetallic composite plate forming method includes:

[0074] Step 1, install the first composite board, manually pull back the two groups of splints 2243 of the clamping assembly 22, then place the first composite board 10 on the installation frame 223, and use the reset of the compression spring 2242, the two groups of splints 2243 Clamp the two sets of splints 2243 to make them drive backward along the transmission assembly a21;

[0075] Step 2, the second composite board is installed, and in synchronization with the step 1, the second composite board 20 is manually placed on the supporting plate 321 of the supporting component 32, and is driven backward along with the transmission component b31;

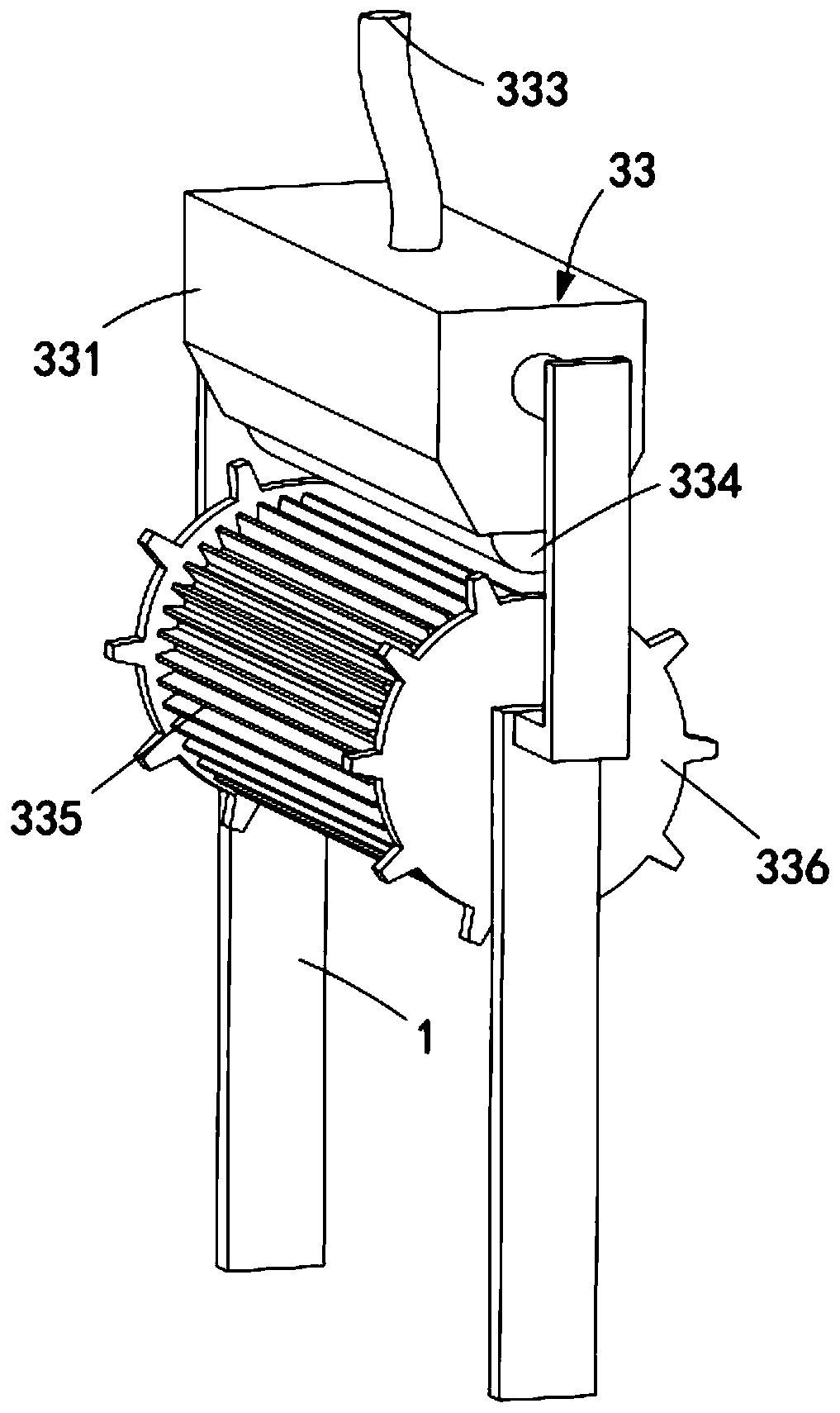

[0076] Step 3, the second composite board is glued, the second composite board 20 being conveyed is meshed with the feeding roller 335 and rotated, and the synchronous bump 336 is set in discontinuous contact with the floating...

Embodiment 2

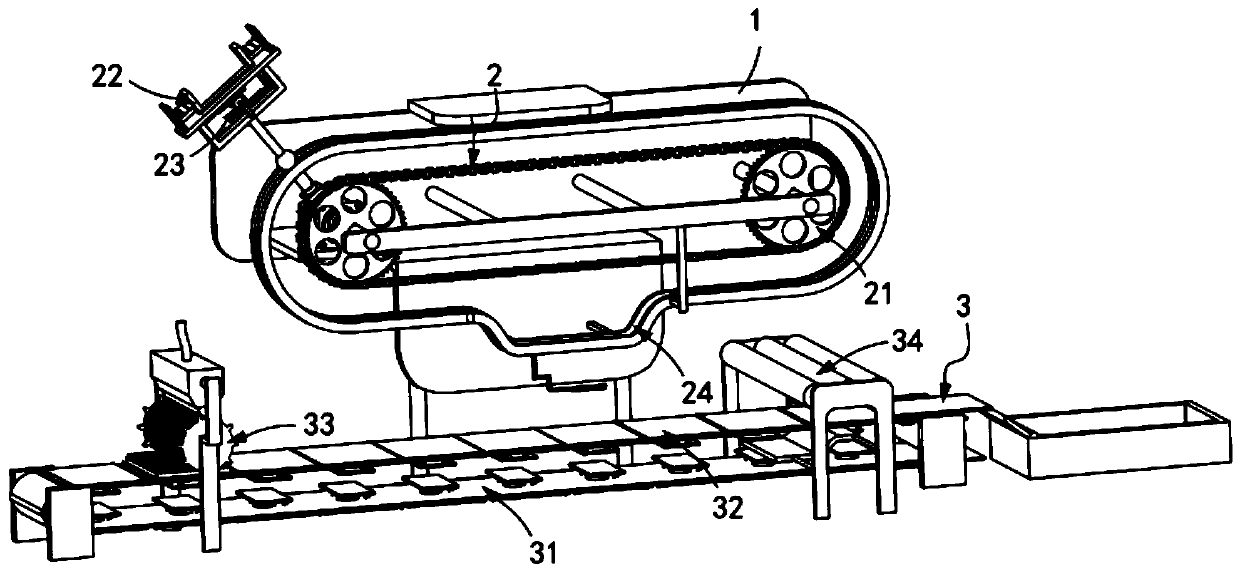

[0092] like figure 2 , Figure 11 As shown, a zigzag metal composite plate bonding equipment includes a frame 1, and also includes a first composite plate mounting mechanism 2 and a second composite plate mounting mechanism 3 installed on the frame 1, the first composite plate The plate mounting mechanism 2 is located above the second composite plate mounting mechanism 3;

[0093] The first composite board loading mechanism 2 includes a transmission assembly a21, a clamping assembly 22 installed on the transmission assembly a21, and the release of the first composite board 10 on the clamping assembly 22 in cooperation with the clamping assembly 22. Components 23 and guide components 24 positioned below the transport component a21; and

[0094] The second composite board loading mechanism 3 includes a transmission assembly b31, a support assembly 32 installed on the transmission assembly b31, a glue application assembly 33 arranged at the input end of the transmission assemb...

Embodiment 3

[0130] like Figure 14 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0131] further, such as Figure 14 As shown, the guide assembly 24 is a guide rail a, the guide rail a is installed on the frame 1 and includes an arc portion a241, a horizontal portion a242 and an arc portion b243 of transitional connection; The part a241 is inclined downward along the transmission direction of the transmission assembly a21, and the arc part b243 is inclined upward along the transmission direction of the transmission assembly a21;

[0132] The limit seat 225 is connected with the guide track a in a smooth transition, and there are slide grooves 244 thereon, and the telescopic tube 222 is provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com