Method for detaching vacuum carrier roller type central spindle of high-speed household paper machine

A roller and vacuum technology, which is applied in the field of dismantling the shaft core of vacuum rollers in high-speed household paper machines, can solve the problems of increasing the labor force of operators, shortening the service life of equipment, and unusable equipment due to damage, so as to shorten the disassembly time and improve Disassembly efficiency, effect of reducing wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

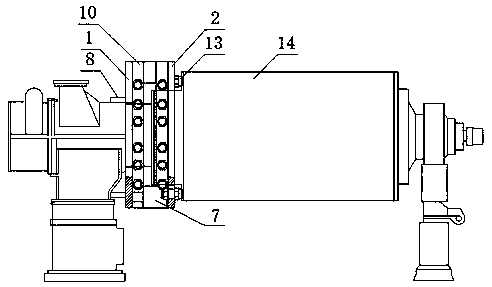

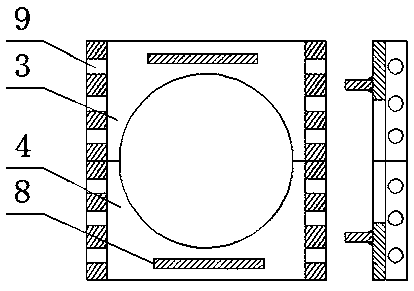

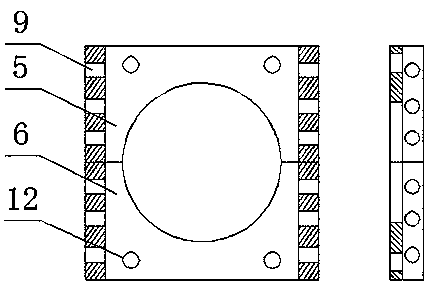

[0032] When using this device, the first support plate 1 and the second support plate 2 are respectively installed on the predetermined positions on the vacuum roller body through the connecting plate 10 and the fastening bolts, so that the baffle plate 8 and the vacuum roller body 14 The bracket is in contact with each other, the top wire 13 is in contact with the end cover, and a hydraulic jack 7 is evenly arranged between the first support plate 1 and the second support plate 2, and then the hydraulic jack is controlled to work so that the first support plate 1 and the second support plate The distance between the plates 2 increases, and then the top wire will make the shaft core out (the working process is similar to the process of separating the sword from the scabbard), and complete the disassembly of the shaft core; The shaft core is disassembled, which shortens the disassembly time, improves the disassembly efficiency, reduces the number of operators involved, and reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com