Vegetable and fruit storage equipment based on PLC

A technology of equipment, fruits and vegetables, applied in the field of PLC control, can solve the problem that the temperature and humidity inside the equipment cannot be kept constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

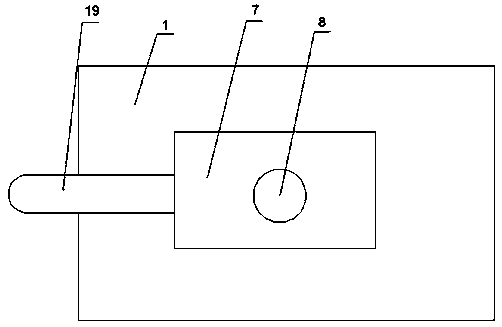

[0023] Such as Figure 1-2 As shown, the fruit and vegetable storage device based on PLC control according to the embodiment of the present invention includes a housing 1, the bottom of the housing 1 is provided with a control seat 2, and the bottom of the housing 1 is provided with a gravity plate 3. The bottom end of the gravity plate 3 is provided with a number of matching rods 4, the bottom end of the matching rod 4 is provided with an induction spring 5 matched with the control seat 2, and the top end of the housing 1 is provided with a spring that is compatible with the control seat 2. The spray cover 6 matched with the seat 2, the top of the spray cover 6 is provided with a control distribution frame 7, the top of the control distribution frame 7 is provided with a water receiving pipe 8 matched with it, and the middle of the bottom of the control distribution frame 7 The position is provided with a first water outlet pipe 9, and the bottom end of the first water outlet...

Embodiment 2

[0027] Such as Figure 1-2 As shown, the two sides of the bottom of the split spray rack 11 are respectively provided with spray ports 13. It is not difficult to see from the above design that the spray ports 13 make the water flow of the equipment more uniform and constant pressure, and avoid the uneven flow of the liquid as a whole. Make the device more stable;

[0028] One side of the bottom of the housing 1 is provided with a drain port 14, and the side of the drain port 14 away from the housing 1 is provided with a drain valve 15 matched with the control seat 2, which is not ugly from the above design Out, the drain valve 15 enables the switch and flow of the drain port 14 to be controlled, so that the control is more convenient and flexible;

[0029] The fitting rod 4 is provided with a sealing limit sleeve 16 that matches the housing 1. It is not difficult to see from the above design that the seal limit sleeve 16 enables the equipment to better cooperate with other st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com