Method and device for optical surface measurement by means of a confocal sensor

An optical measurement and sensor technology, applied in the field of confocal sensors, can solve the problem that the readout speed cannot be further improved easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

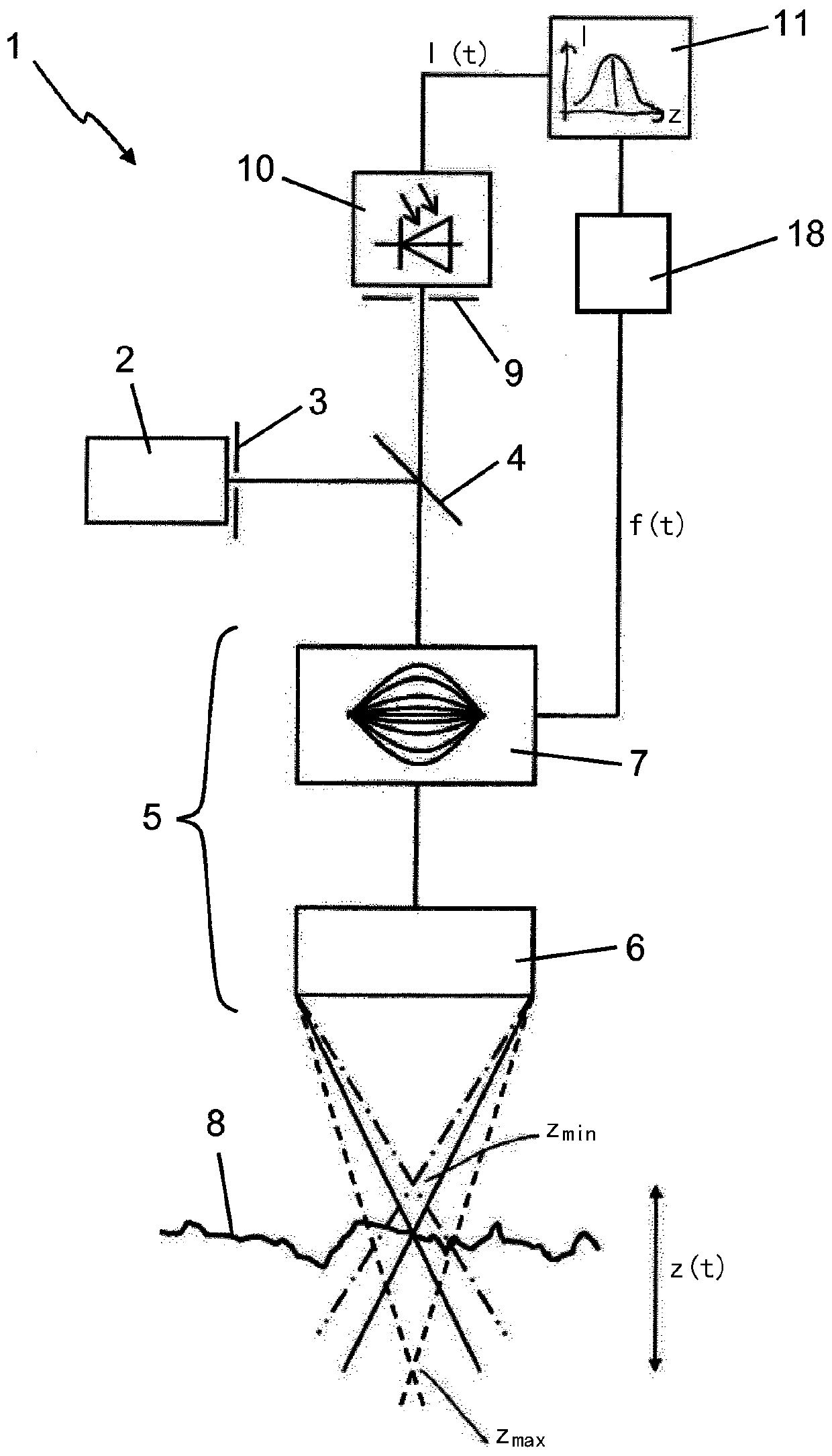

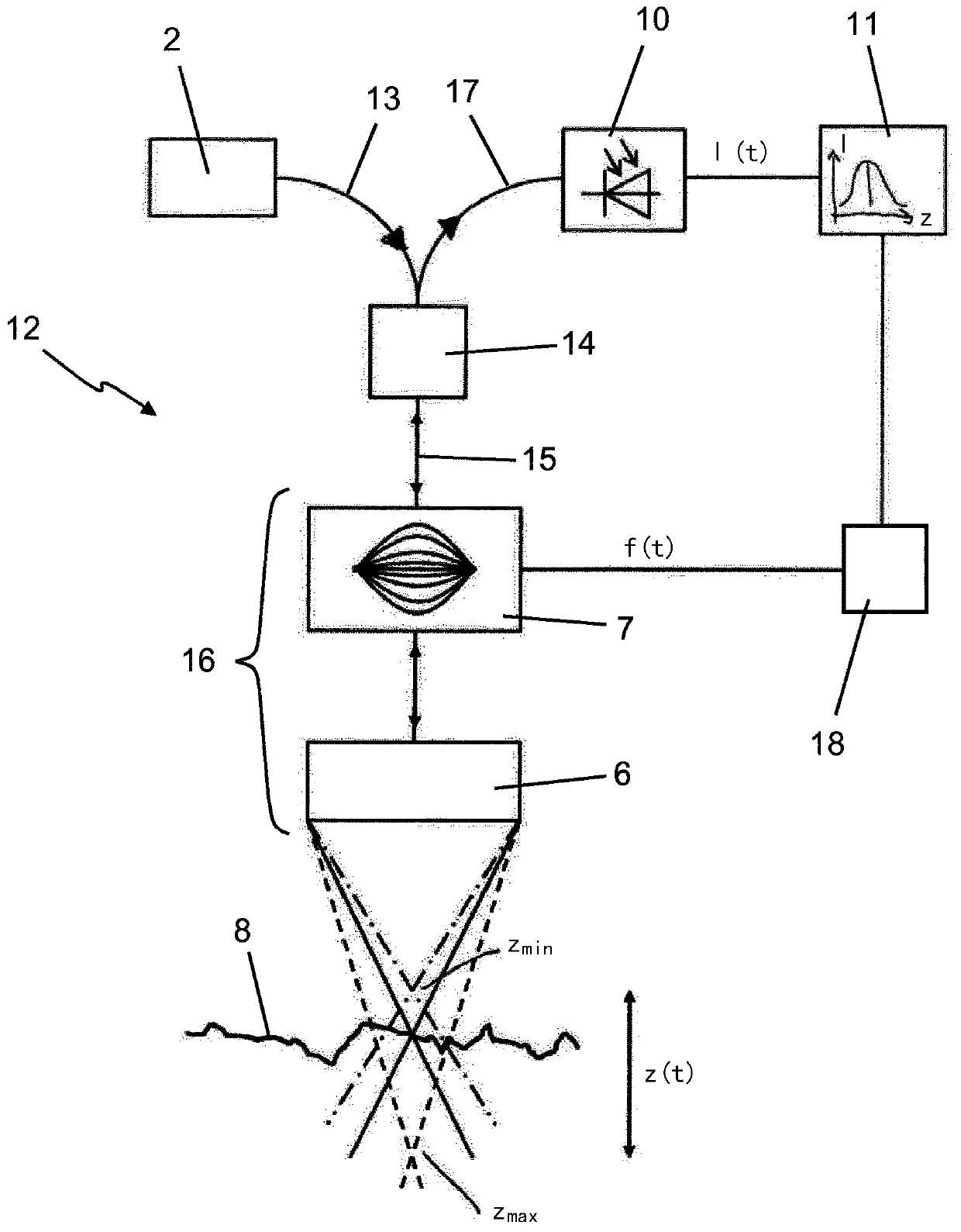

[0034] exist figure 1 A confocal sensor is shown in and is collectively assigned the reference number 1 . An essential component of such a confocal sensor 1 is, on the one hand, the light source, preferably a suitable laser, provided with the reference numeral 2 . A laser 2 sends its light through a confocal filter (pinhole) 3 to an optical system 5 via a beam splitter 4 (in the present embodiment, a semi-transparent mirror), which The optical system consists of objective lens 6 and TAG lens 7. The TAG lens is acted upon by means of an electrical signal f(t) generated by a function generator 18 . This leads to the fact that in the light-transmissive material of the TAG lens 7, due to the acousto-optic effect, the radial profile of the refractive index n versus the electrical signal is a function of time. The light is thus focused at different heights in the Z direction corresponding to the signal f(t) and directed at the sample 8 drawn. The focus position is preferably per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com