Display mother board and preparation method of display panel

A display panel and motherboard technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of unfavorable narrow frame design of organic light-emitting display panels and low substrate utilization rate of display motherboards, and achieve reduction Small frame, improve utilization rate, and realize the effect of close packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

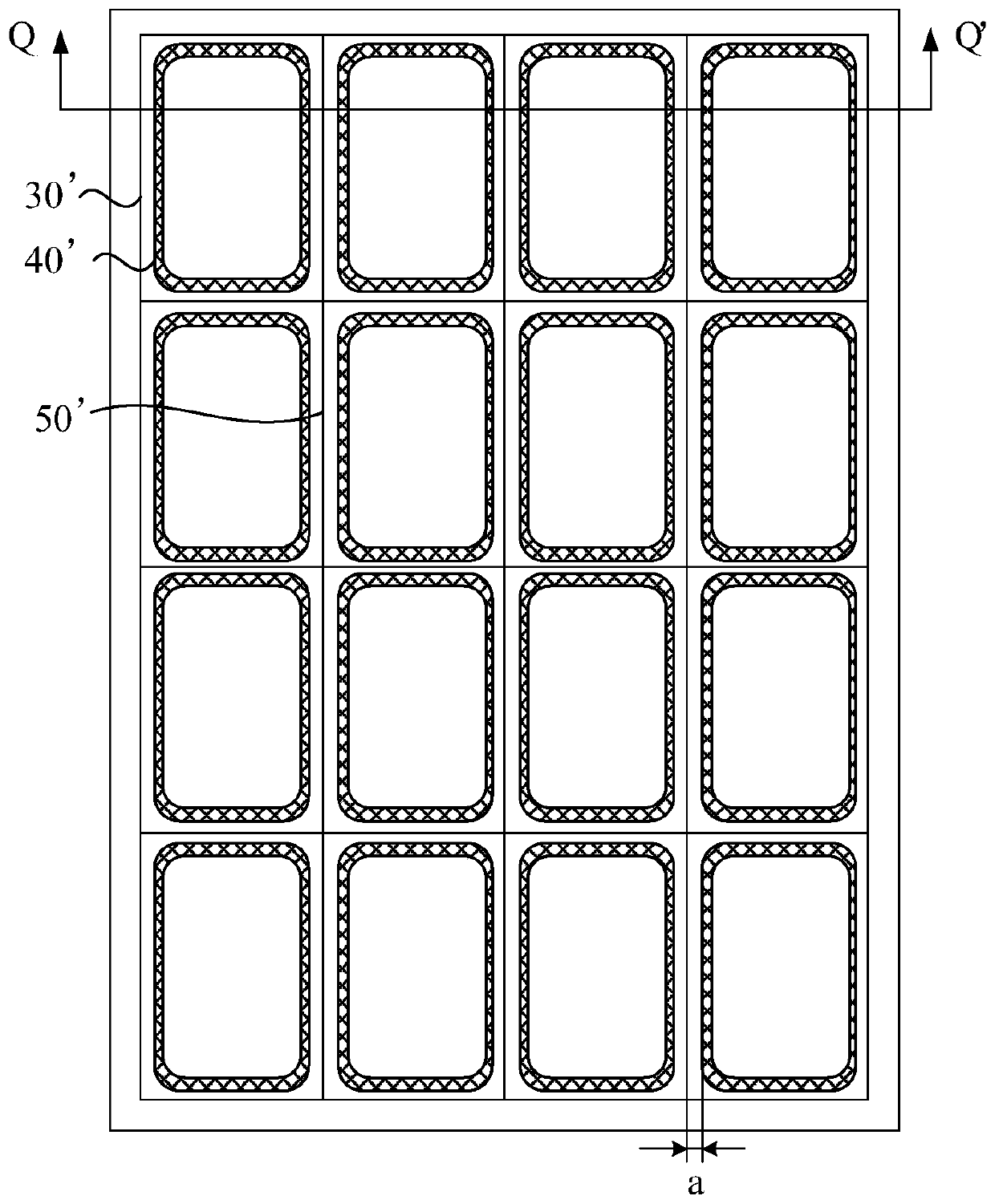

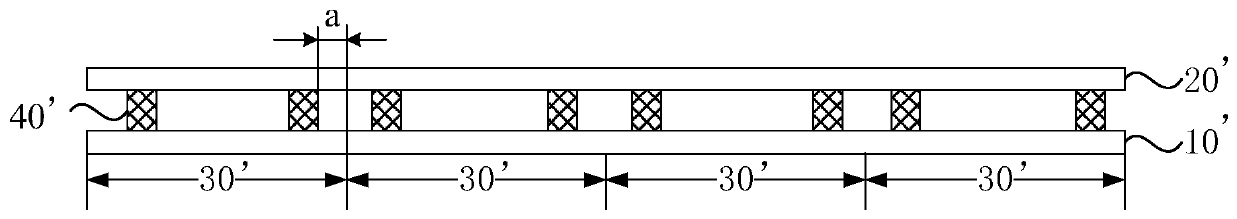

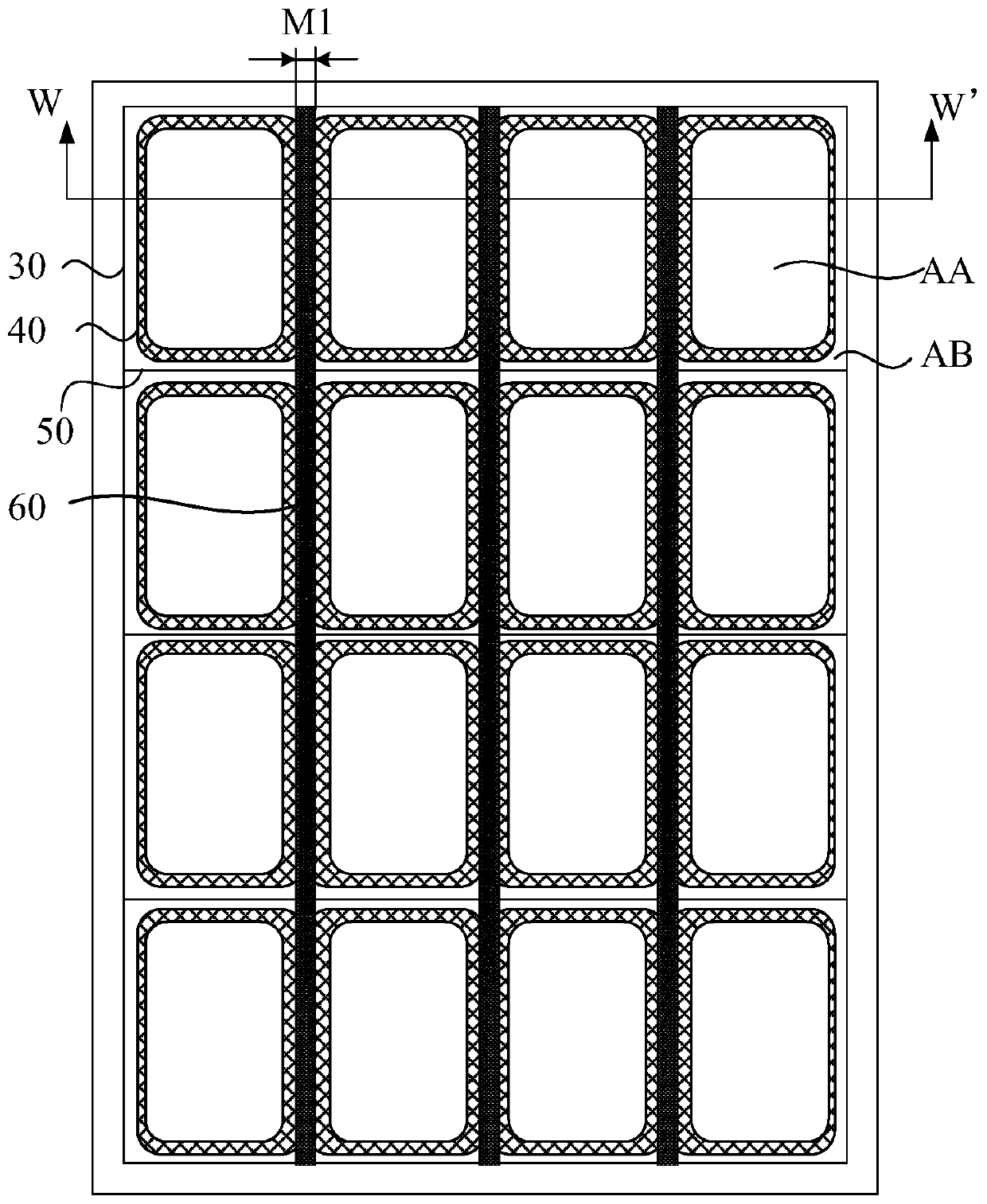

[0031] figure 1 It is a structural schematic diagram of a display motherboard in the prior art, figure 2 yes figure 1 The cross-sectional view along the QQ’ direction, such as figure 1 and figure 2 As shown, the existing display motherboard includes an organic light emitting display array motherboard 10' and a cover motherboard 20', and also includes a plurality of organic light emitting display panel regions 30'. Apply glass glue 40' on the cover motherboard 20' corresponding to the peripheral area of eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com