A kind of magnetron sputtering method of BGA electromagnetic shielding product

A magnetron sputtering and electromagnetic shielding technology, applied in the field of magnetron sputtering, can solve problems such as solder ball damage, ejection, affecting product appearance and performance, and achieve the effect of protection without damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

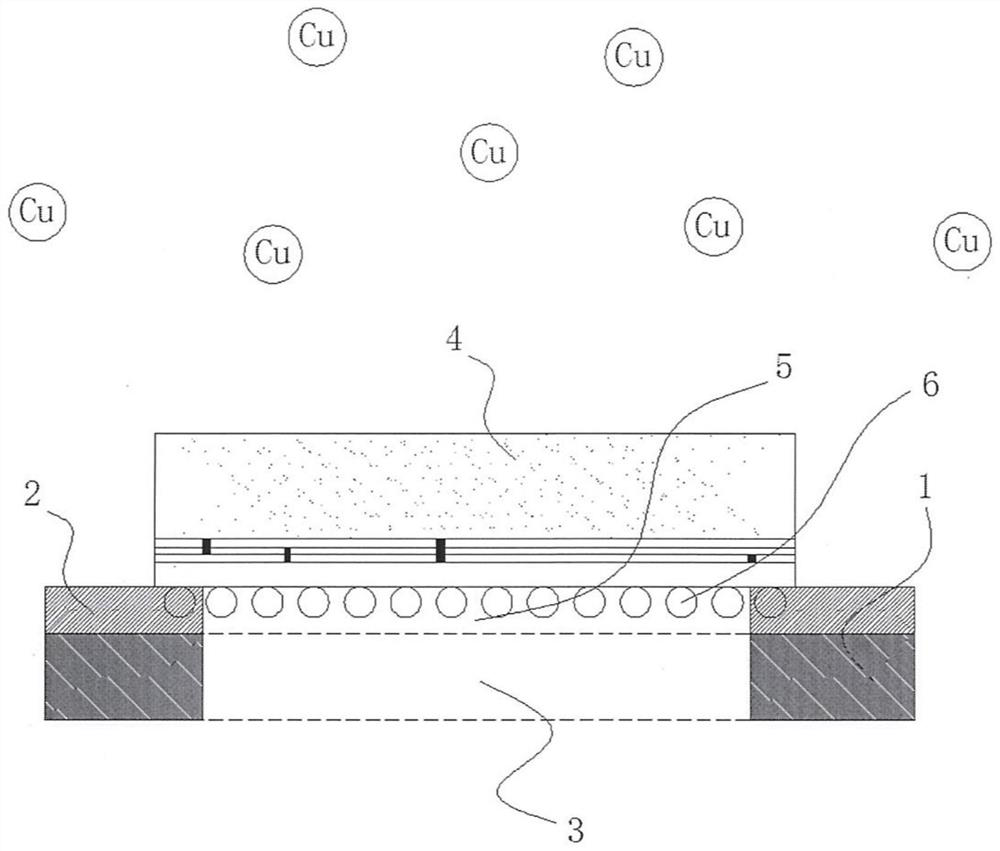

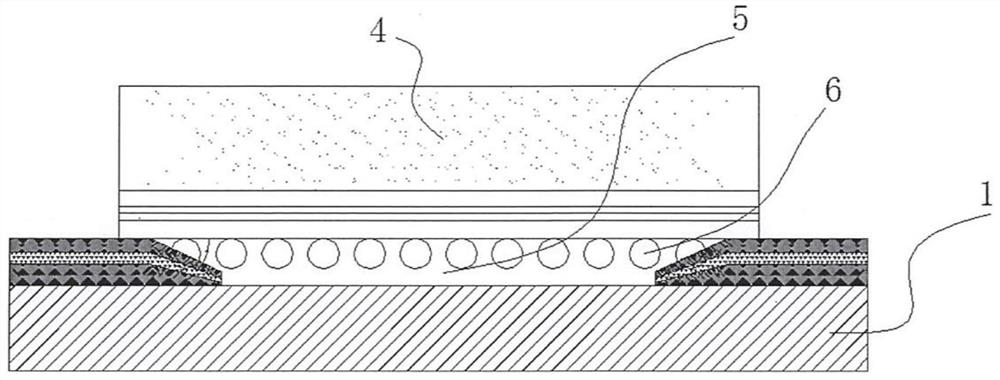

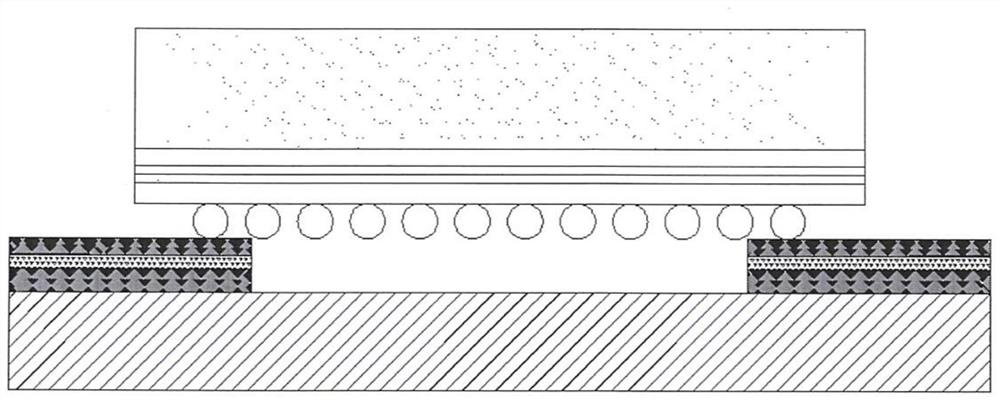

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] The magnetron sputtering method of a kind of BGA electromagnetic shielding product that the present invention relates to, it comprises the following steps:

[0034] Step 1. Take a sputtering tape;

[0035] The sputtering tape has a three-layer structure, the base layer is a pressure-sensitive acrylic adhesive layer, the middle layer is a plastic memory metal layer, and the top layer is a pressure-sensitive acrylic adhesive layer;

[0036] Step 2. Use a punching die to punch through holes of corresponding size on the sputtering tape, and form a slope on the surface of the sputtering tape near the edge of the through hole by heating and pressing. Under high temperature and high pressure conditions, the plastic memory metal film will Form memory deformation, and after returning to normal temperature, the deformation still maintains the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com