Pressure machine capable of driving balance mechanism

A technology of balance mechanism and press, which is applied in the field of press components, can solve the problems of poor balance, difficult processing, troublesome assembly, etc., and achieve the effect of meeting the requirements of use, good dynamic balancing effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

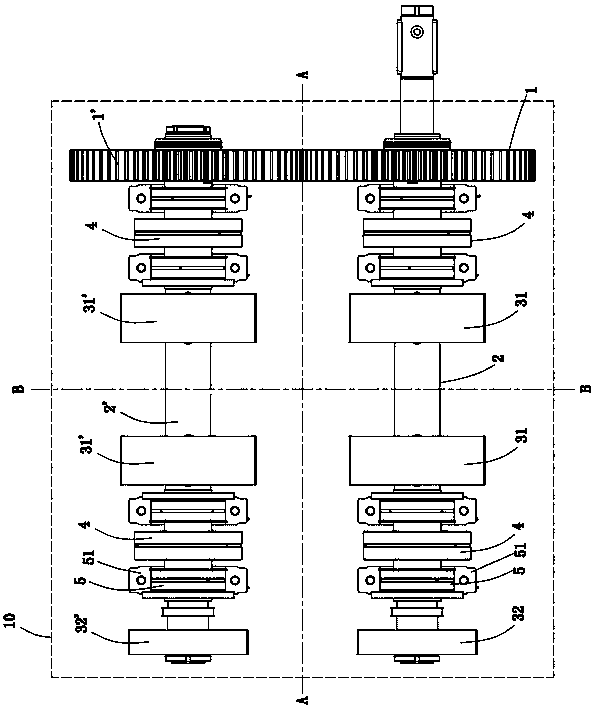

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] For the convenience of description, according to the direction of the accompanying drawings, the A-A centerline and B-B centerline in the figure are determined to be the front and rear centerlines and left and right centerlines of the press respectively, but the determination of the A-A centerline and B-B centerline does not constitute protection for the present invention Limitations on Content and Scope.

[0014] Such as Figure 1-3 As shown, a press includes a base 6, a slider 7, a column 8, an upper beam 10 and a dynamic balance mechanism.

[0015] There are four columns 8, which are respectively installed on the four corners of the base 6, and the upper beam 10 is supported by the columns 8 to form the frame of the press.

[0016] The first transmission shaft 2 and the second transmission shaft 2' are rollingly supported by the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com