Feeding control method, device and system

A control system and feeding technology, which are applied in animal feeding devices, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems that the feeding trough cannot be automatically flushed, and the simultaneous distribution of multiple feeding troughs cannot be performed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

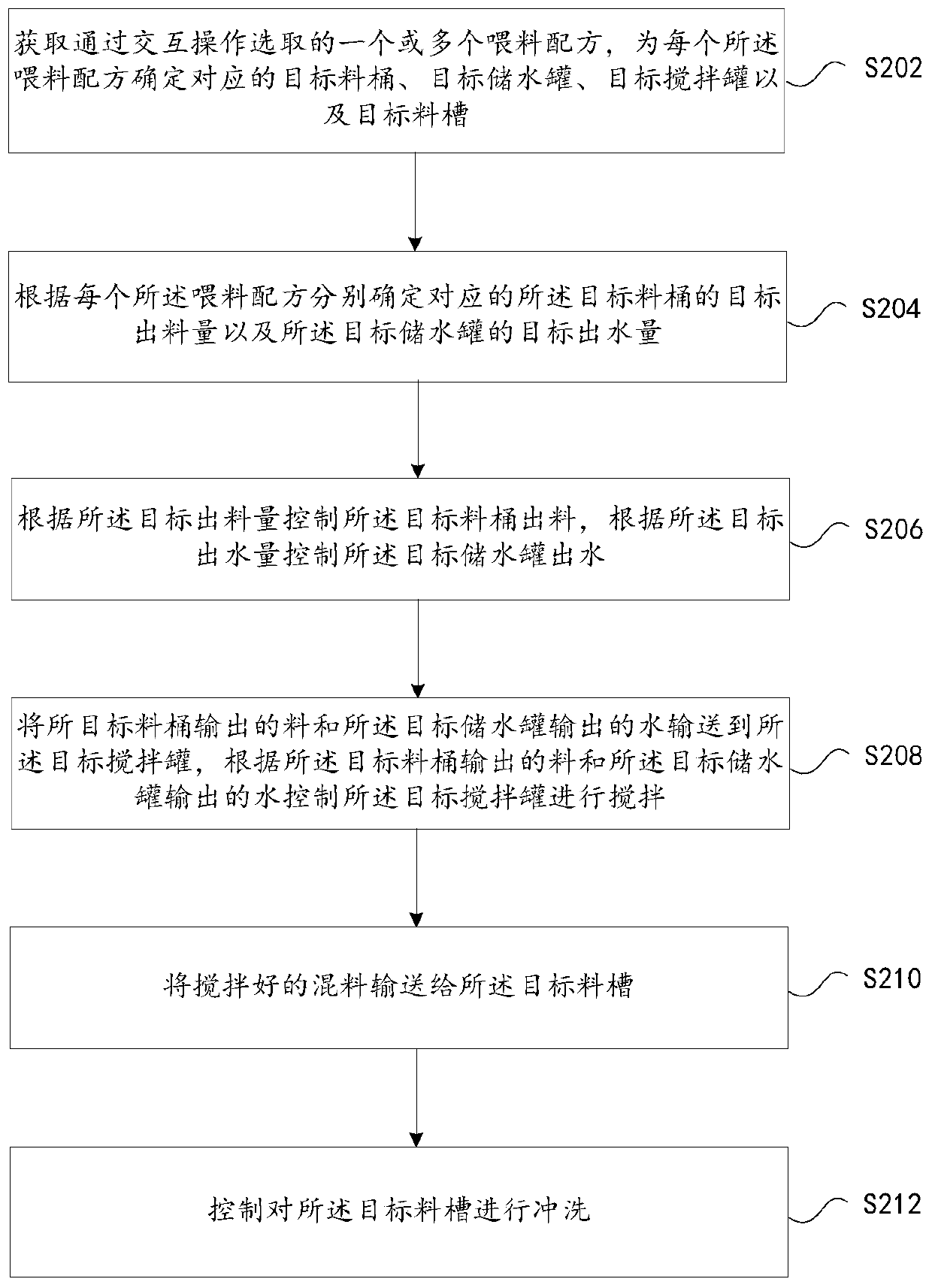

[0087] The method embodiment provided in Embodiment 1 of the present application may be executed in a mobile terminal, a computer terminal, or a similar computing device. Taking running on a mobile terminal as an example, figure 1 It is a block diagram of the hardware structure of a mobile terminal of a feeding control method according to an embodiment of the present invention, as figure 1 As shown, the mobile terminal 10 may include one or more ( figure 1 Only one is shown in the figure) a processor 102 (the processor 102 may include but not limited to a processing device such as a microprocessor MCU or a programmable logic device FPGA) and a memory 104 for storing data. Optionally, the above-mentioned mobile terminal also A transmission device 106 for communication functions as well as input and output devices 108 may be included. Those of ordinary skill in the art can understand that, figure 1 The shown structure is only for illustration, and does not limit the structure...

Embodiment 2

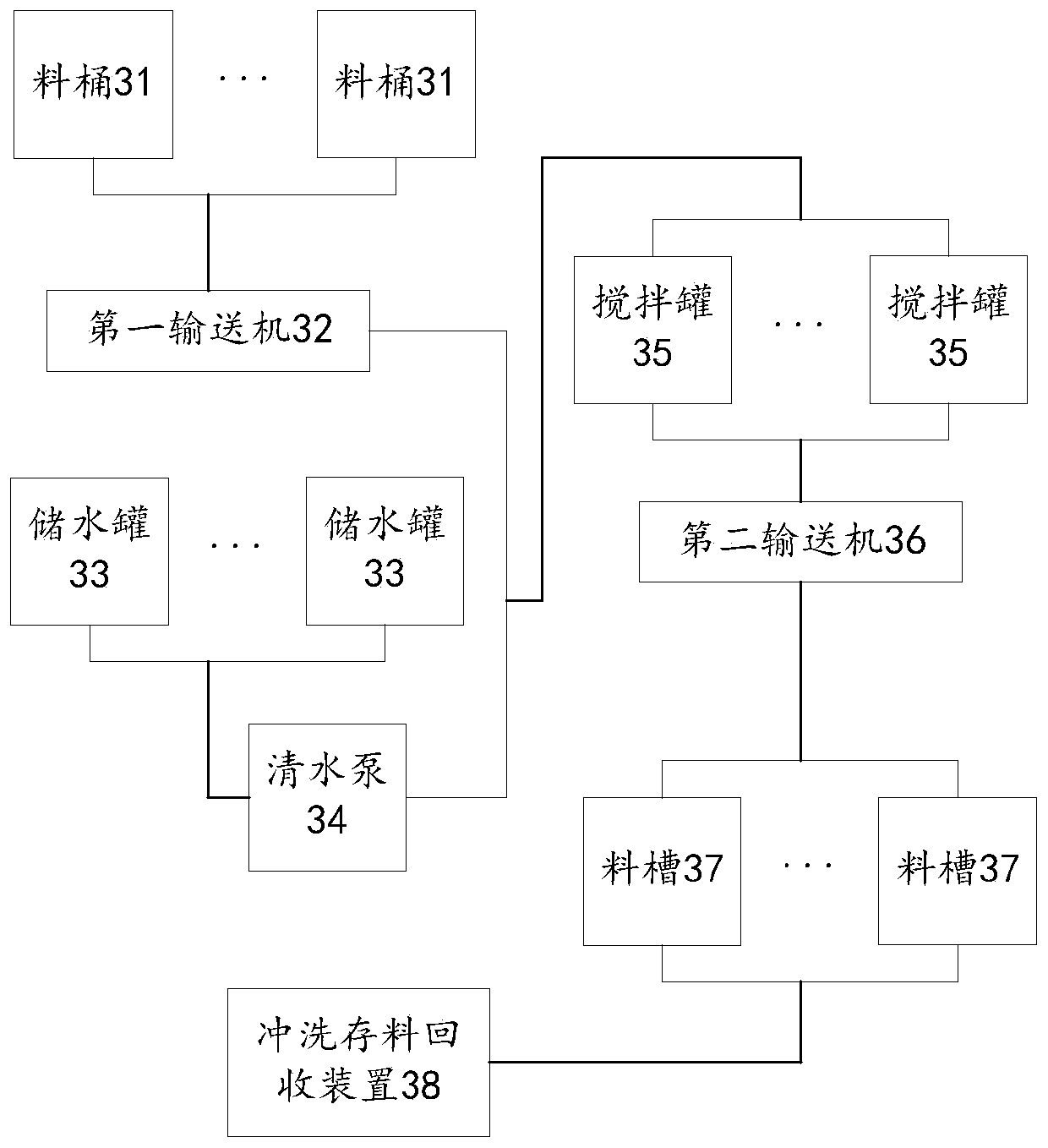

[0104] According to one embodiment of the present invention, a feeding control system is provided, image 3 is a schematic diagram of a feeding control system according to an embodiment of the present invention, such as image 3 As shown, it includes: a plurality of material barrels 31, a first conveyor 32, a plurality of water storage tanks 33, a clean water pump 34, a plurality of mixing tanks 35, a second conveyor 36, a plurality of troughs 37, and flushing storage recovery device 38 and a controller (not shown in the figure), wherein, the plurality of buckets 31 are respectively connected to the first conveyor 32, and the plurality of water storage tanks 33 are respectively connected to the clean water pump 34, The first conveyor 32 and the clean water pump 34 are connected to the plurality of stirring tanks 35 after being combined through the transmission pipeline, and the plurality of stirring tanks 35 are respectively connected to the second conveyor 36. Two conveyors ...

Embodiment 3

[0141] The embodiment of the present invention also provides a feeding control device, which is used to implement the above-mentioned embodiments and preferred implementation modes, and what has been explained will not be repeated. As used below, the term "module" may be a combination of software and / or hardware that realizes a predetermined function. Although the devices described in the following embodiments are preferably implemented in software, implementations in hardware, or a combination of software and hardware are also possible and contemplated.

[0142] Figure 6 is a block diagram of a feeding control device according to an embodiment of the present invention, such as Figure 6 shown, including:

[0143] An acquisition module 62, configured to acquire one or more feeding formulas selected through interactive operations, and determine a corresponding target material bucket, target water storage tank, target mixing tank, and target material trough for each of the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com