Intelligent fresh-keeping and humidifying air source heat pump drying chamber

An air source heat pump and drying room technology, which is applied in the field of tobacco leaf humidification and rehydration, agricultural product refrigeration and preservation, and air source heat pump tobacco leaf drying, can solve the problems of tobacco leaf humidification and rehydration, and achieve simple structure, reasonable design, and improved baking quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1, after the tobacco leaves are dried, the tobacco leaves need to be humidified and rehydrated. At present, the heat pump dryer is often used to dry the tobacco leaves, but the function of the heat pump dryer is relatively simple. It can realize the drying function of the tobacco leaves, but it cannot realize the humidification and moisture resurgence of the tobacco leaves after the tobacco leaves are dried. If the moisture content is very low, the tobacco leaves will be damaged, and the artificial humidification method will cause the tobacco leaves to absorb moisture unevenly and cause rotten leaves, which will cause economic losses to the tobacco farmers.

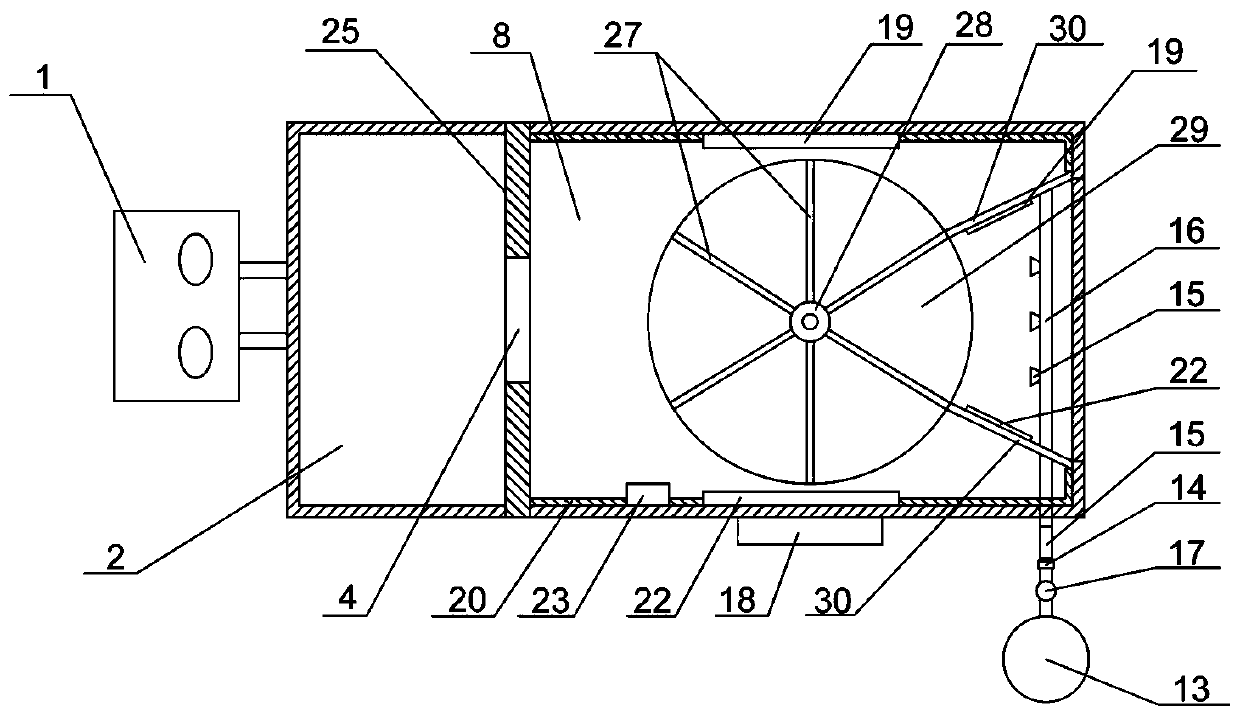

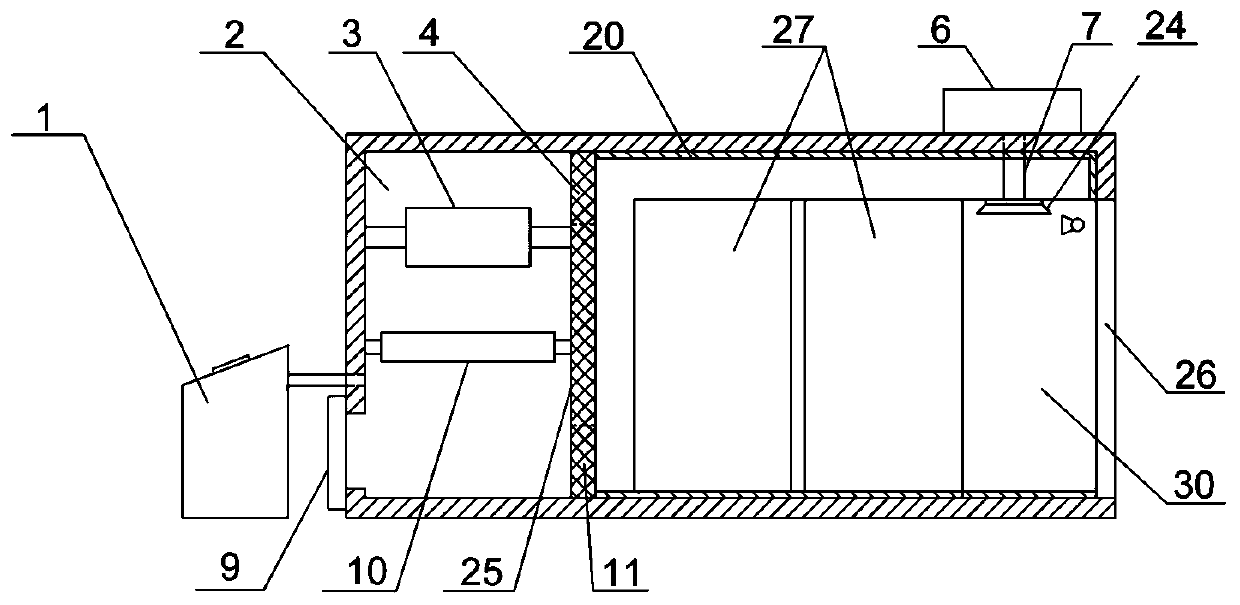

[0030] In view of the above problems, the present invention provides an intelligent fresh-keeping and humidifying air source heat pump drying room, such as Figure 1-2As shown, it includes the whole drying room. The inside of the drying room includes a first chamber 2 for energy conversion and a second cham...

Embodiment 2

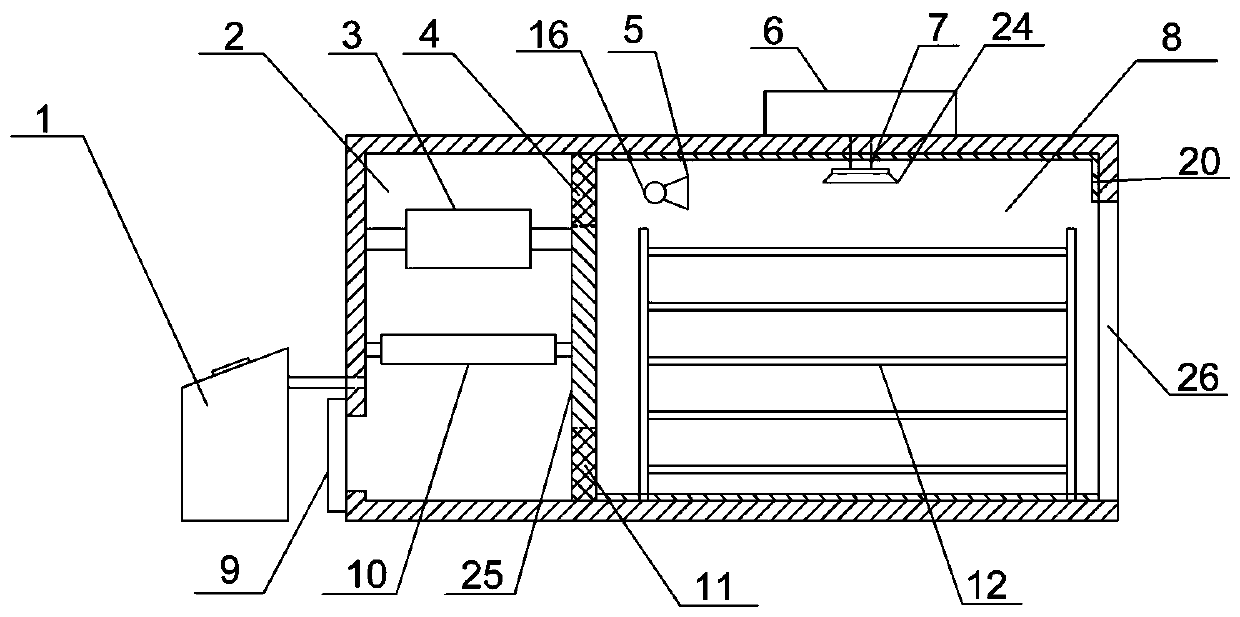

[0038] Example 2, such as Figure 3-5 As shown, it includes the whole drying room. The inside of the drying room includes a first chamber 2 for energy conversion and a second chamber 8 for storing materials. Between the first chamber 2 and the second chamber 8, there is a A partition 25, the partition 25 is vertically fixed between the first chamber and the second chamber, a rectangular air inlet 4 runs through the top middle of the partition 25, and a rectangular air inlet 4 runs through the bottom middle of the partition 25. Air return port 11; a circulating fan 3 is fixedly installed above the interior of the first chamber 2, and the circulating fan 3 can promote the air circulation in the first chamber 2 and the second chamber 8, and a replacement fan is fixedly installed below the circulating fan 3 The heater 10 is provided with a fresh air inlet below the front end of the first chamber 2, and a fresh air valve 9 is installed on the fresh air inlet. When the fresh air val...

Embodiment 3

[0041] Embodiment 3, an intelligent fresh-keeping and humidifying air source heat pump drying room in this implementation will be described centering on the differences from Embodiment 1.

[0042] In this embodiment, a pressure-touch switch is provided on the sealing strip at the head end of the fixed wall 30, and the pressure-touch switch is electrically connected to the PLC controller. At the end, the pressure touch switch on the sealing strip is triggered, and the pressure touch switch will send a signal to the PLC controller. After the PLC receives the signal, it will open the solenoid valve and start the high-pressure atomizing pump, so that the moving wall and the fixed wall The tobacco leaves in the sealed chamber formed between are humidified and regained moisture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com