Anti-overcurrent fine adjustment slide rheostat

A sliding rheostat and overcurrent technology, applied in the direction of sliding contact resistors, adjustable resistors, resistors, etc., can solve the problems of damaged rheostats, inability to finely adjust the resistance, and easy heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

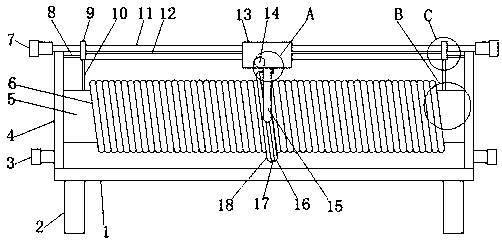

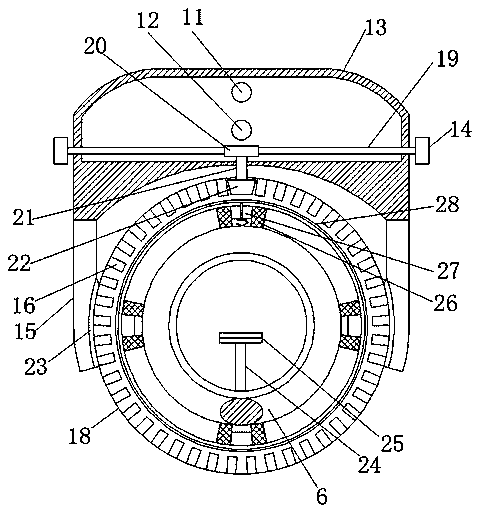

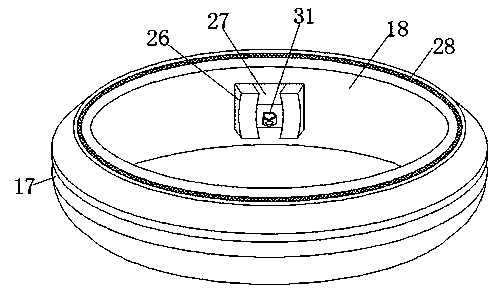

[0030] refer to Figure 1-6 , an anti-overcurrent fine-tuning sliding rheostat, comprising a bottom plate 1, fixed plates 4 are welded on both sides of the top of the bottom plate 1, fixed tubes 5 are welded between the fixed plates 4, fixed columns 24 are welded inside the fixed tubes 5, fixed The top of the column 24 is welded with a bimetallic strip 25, the outside of the fixed tube 5 is sheathed with a resistance wire 6, a second conductor 11 and a third conductor 12 are arranged between the two fixed plates 4, and both ends of the third conductor 12 are A first conductor 9 is rotatably connected, and the top of the fixed tube 5 is provided with two first through holes, and the fixed tube 5 is provided with a moving column 10 at the two first through holes, and the moving column 10 is located between the bimetal sheet 25 and the first through hole. Between one conductor 9, the middle part of the second conductor 11 and the third conductor 12 is provided with a moving body ...

Embodiment 2

[0043] refer to Figure 7 , an anti-overcurrent fine-tuning sliding rheostat. Compared with Embodiment 1, this embodiment increases the practicability of the device and prevents the rotating ring 18 and the resistance wire 6 from falling off when the moving body 13 slides. Both sides of the top of the bottom plate 1 are The limit block 32 is welded, the side of the limit block 32 close to each other is bonded with a rubber pad 33, when the rotating ring 18 moves to both sides, it will contact the rubber pad 33 for buffering, and stop the movement through the limit block 32 .

[0044] When changing the resistance value, moving the moving body 13 can drive the rotating ring 18 to move through the fixed rod 15, and the moving ring 18 drives the elastic sheet 31 to move, and the elastic sheet 31 contacts the different turns of the resistance wire 6, changing the resistance, and the current can pass through The first terminal 3 enters the resistance wire 6, and then enters the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com