Method and device for rapidly detecting and repairing floor tile hollow regions in building

A technology in floor tiles and buildings. It is applied in building maintenance, measuring devices, construction, etc. It can solve problems such as uneven force, heavy workload, and easy omissions, so as to achieve good repair effects, improve accuracy and work efficiency. , to avoid omissions and inaccuracies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: A building is completed, and the floor tiles in the lobby on the first floor are inspected and repaired for hollowing.

[0059] Through the hammer head 201 knocking detection, a certain hollow area is a nearly circular area with an area of 900 square centimeters. A small hole with a diameter of 3 mm is drilled in the center of the area, and the small hole reaches the hollow position through the floor tiles; Inject about 100ml of clean water into the hole, and keep it for 10 minutes after the water injection, so that the clean water penetrates into the cement in the holding area; while vibrating the floor tiles in the hollow area, slowly inject cement into the small hole until the cement in the small hole is no longer absorbed. Until it overflows the small hole, the vibration is to drive out the air bubbles in the hollow area, so that the newly injected cement can fully combine with the original cement. Clean up the excess cement around the small hole and ke...

Embodiment 2

[0060] Example 2: After a building is completed, the hollow floor tiles in the hall on the first floor are detected and repaired by using the rapid detection and repair device for the hollow area of the floor tiles in the building.

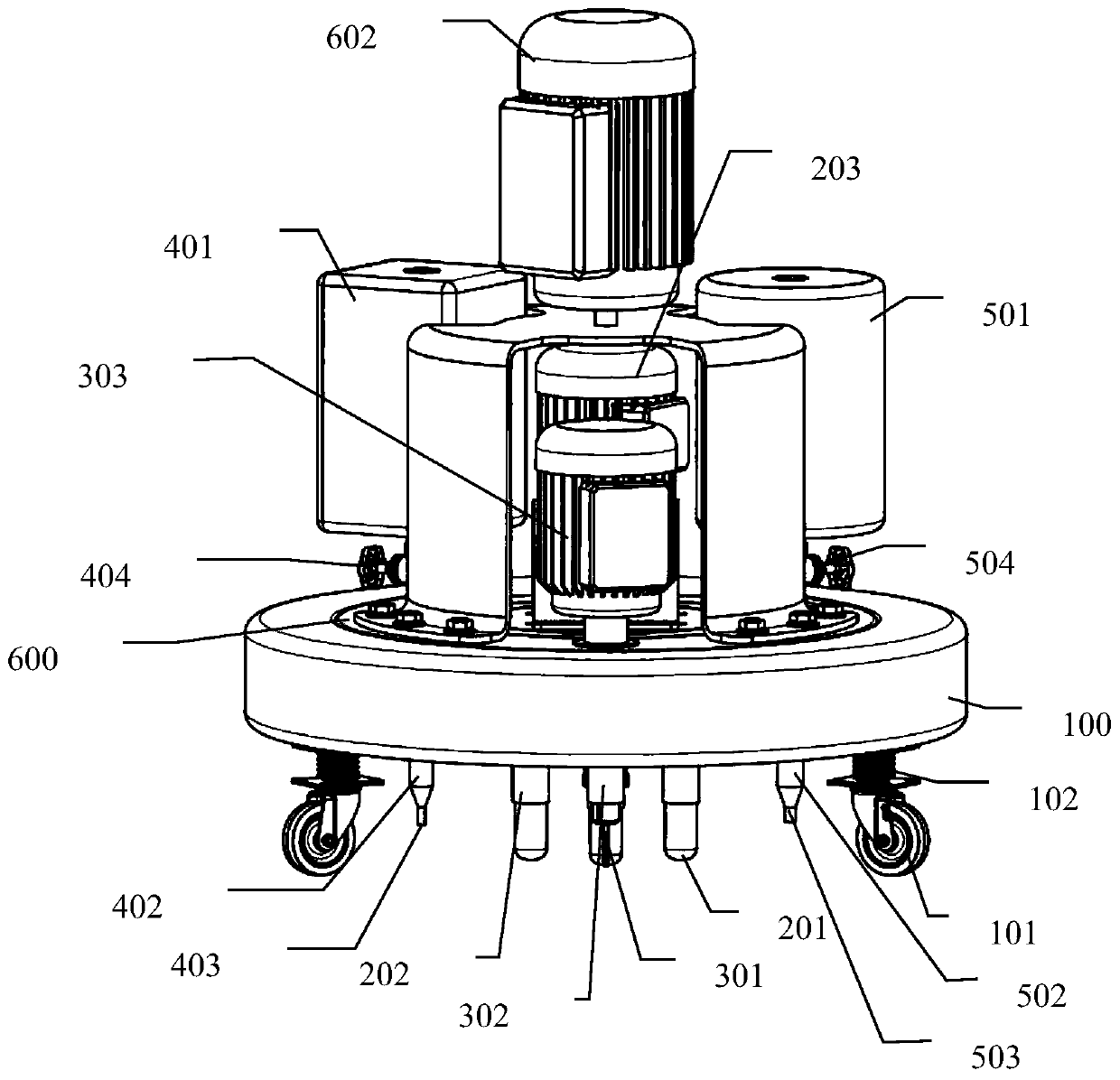

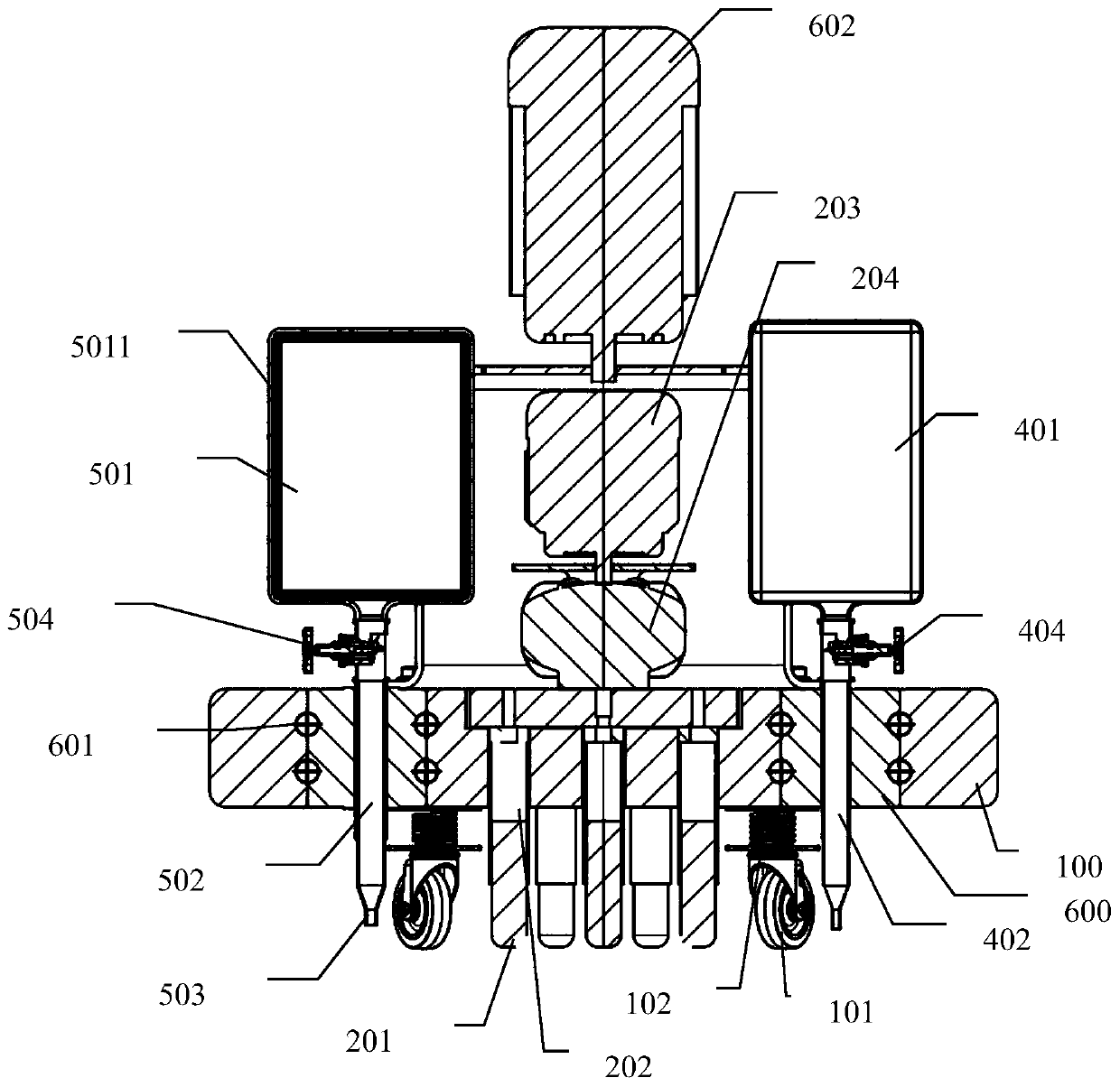

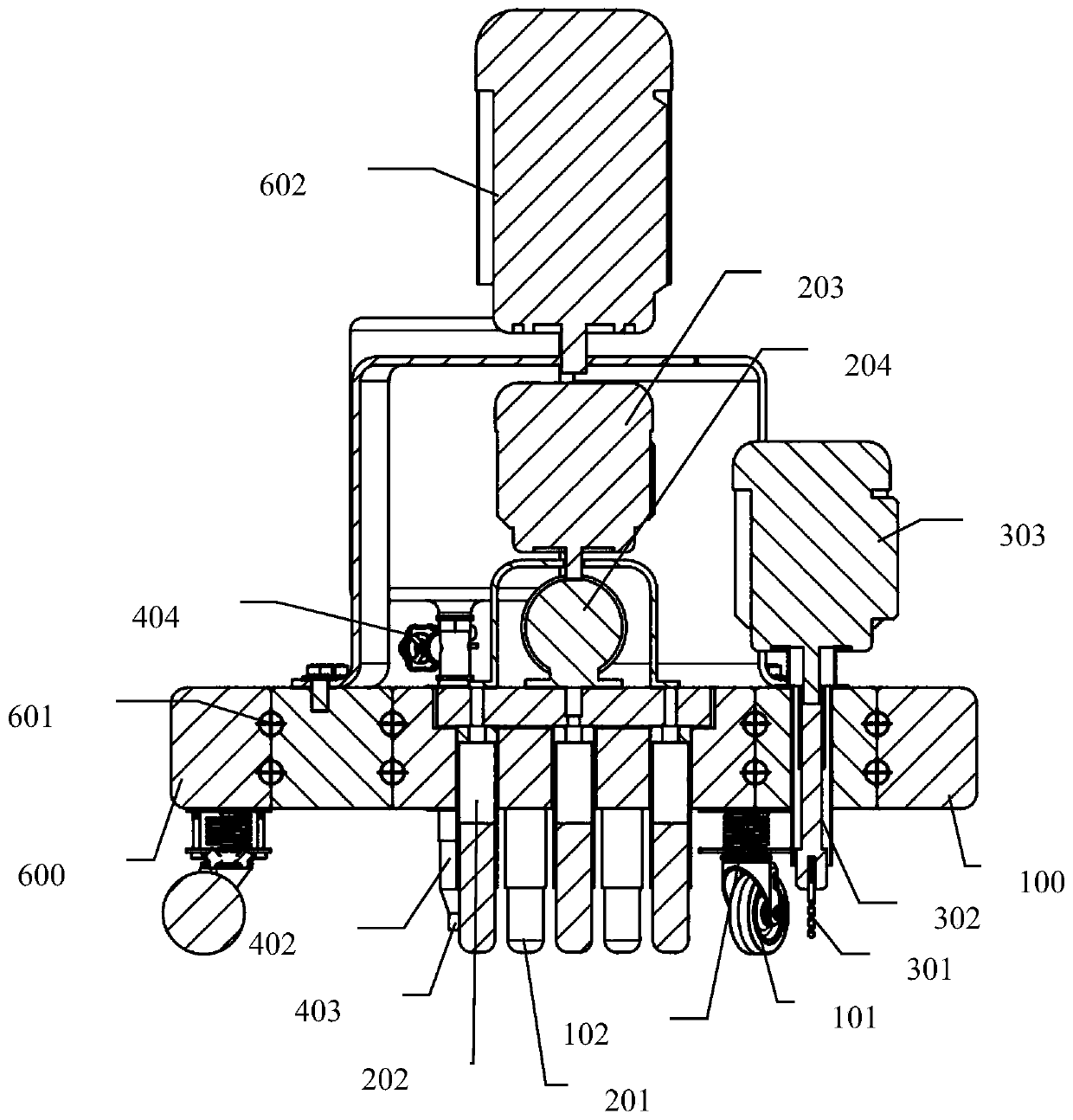

[0061] The first motor 203 drives the telescopic rod to expand and contract, so that the hammer head 201 knocks the floor tiles below, and the knocking audio is transmitted to the processor, and the processor judges whether it is a hollow spot according to the similarity with the comparison audio, and accordingly A near-circular hollow area of approximately 900 cm² was marked for entry into the patching procedure. The controller starts the second motor 303, and the second motor 303 drives the drill rod 302 to extend to the surface of the hollow area of the floor, and rotates to drill a small hole downward; the rotating disk 600 rotates the water injection device to rotate to the small hole position, and the water injection port 403 Align the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com