Construction method for ground cable hanging and aerial butt joint of ultra-large-span prestressed pipe truss

A prestressed tube and aerial docking technology, applied in truss structures, girders, trusses, etc., can solve problems such as high construction costs, many safety hazards, and long working hours at heights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] Such as Figure 1-7 shown.

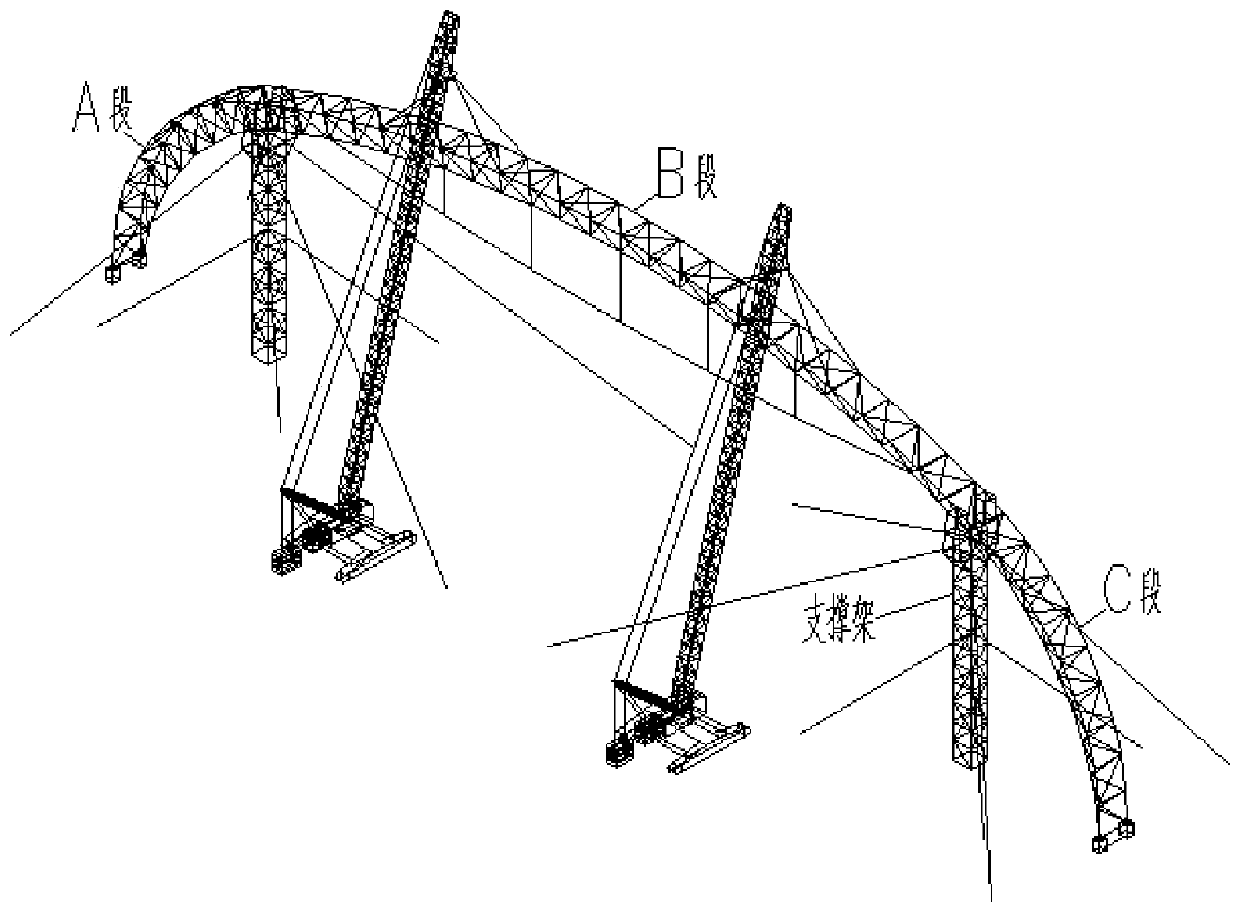

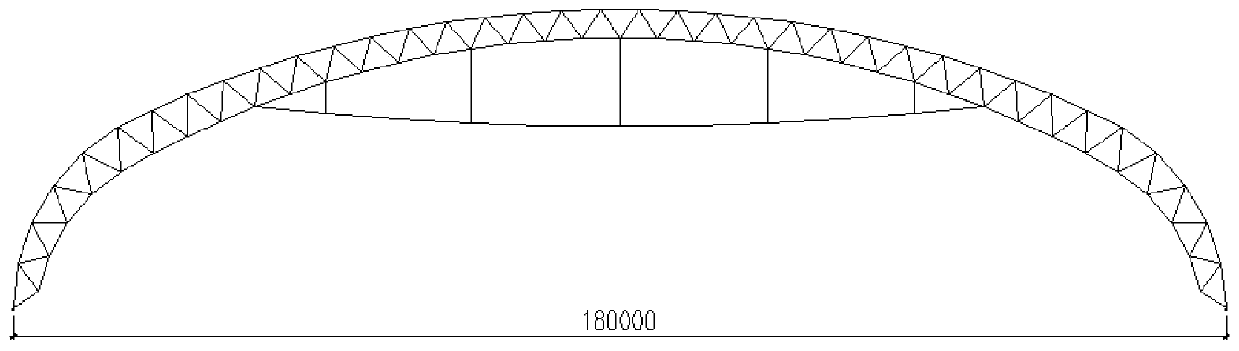

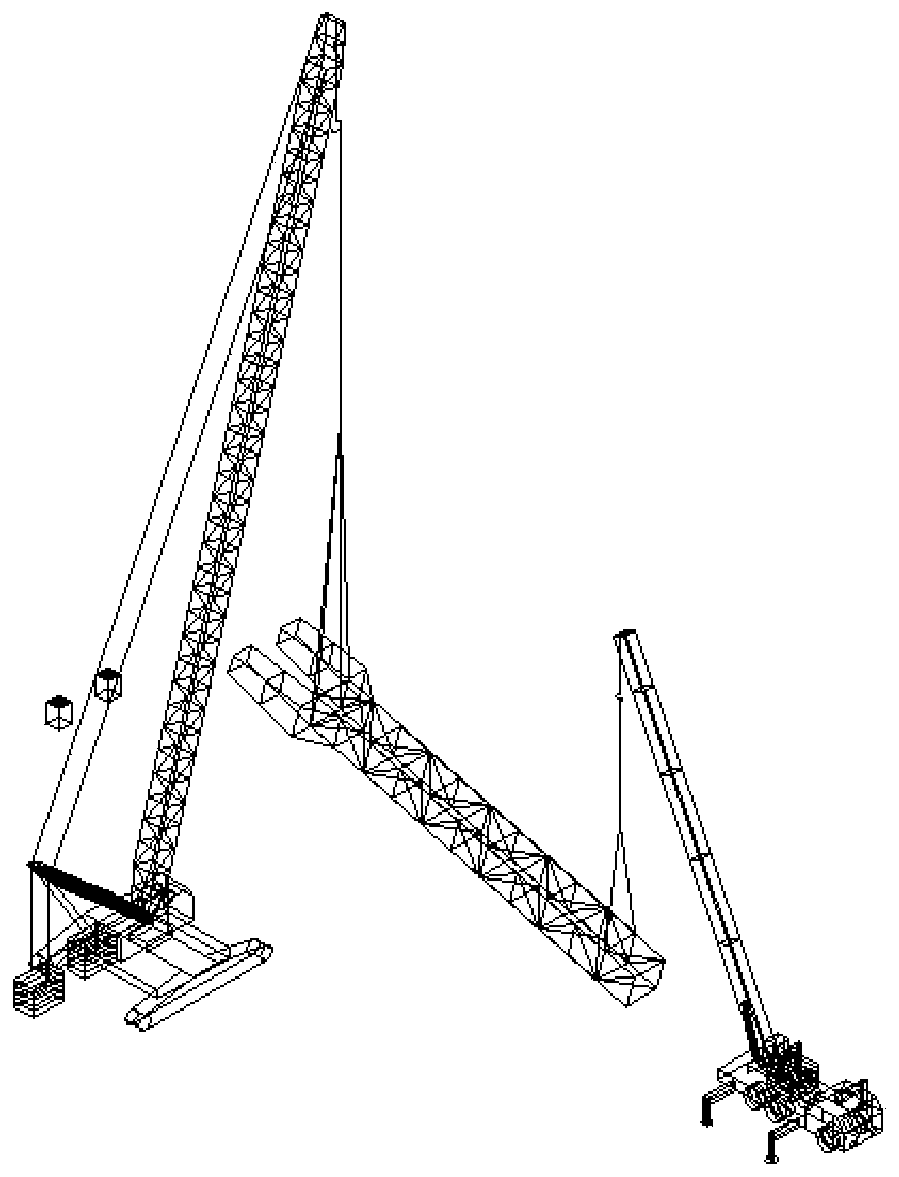

[0030] A construction method for super-large-span prestressed pipe truss ground-hanging cables in the air. According to the position of the end of the cable, the prestressed pipe truss is divided into three sections A, B, and C, such as figure 1 as shown; first hoist sections A and C to the design position (such as image 3 , 4 ), and then assemble B1 and B2 sections on the ground into B section (such as Figure 5 , 6 ), the cable is initially tensioned after the cable is hung on the ground, such as Figure 7 As shown, after the preliminary tensioning is completed, the two machines will lift section B to the design position and dock with sections A and C in the air. After the docking is completed, install the contact truss, and finally stretch the cables to the design requirements.

[0031] The implementation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com