Preparation method of nickel-cobalt-manganese ternary positive electrode spherical material

A nickel-cobalt-manganese, cathode technology, applied in nanotechnology for materials and surface science, chemical instruments and methods, nickel compounds, etc., can solve the problems of high difficulty in operation, large pollution, etc. Performance, the effect of simple continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

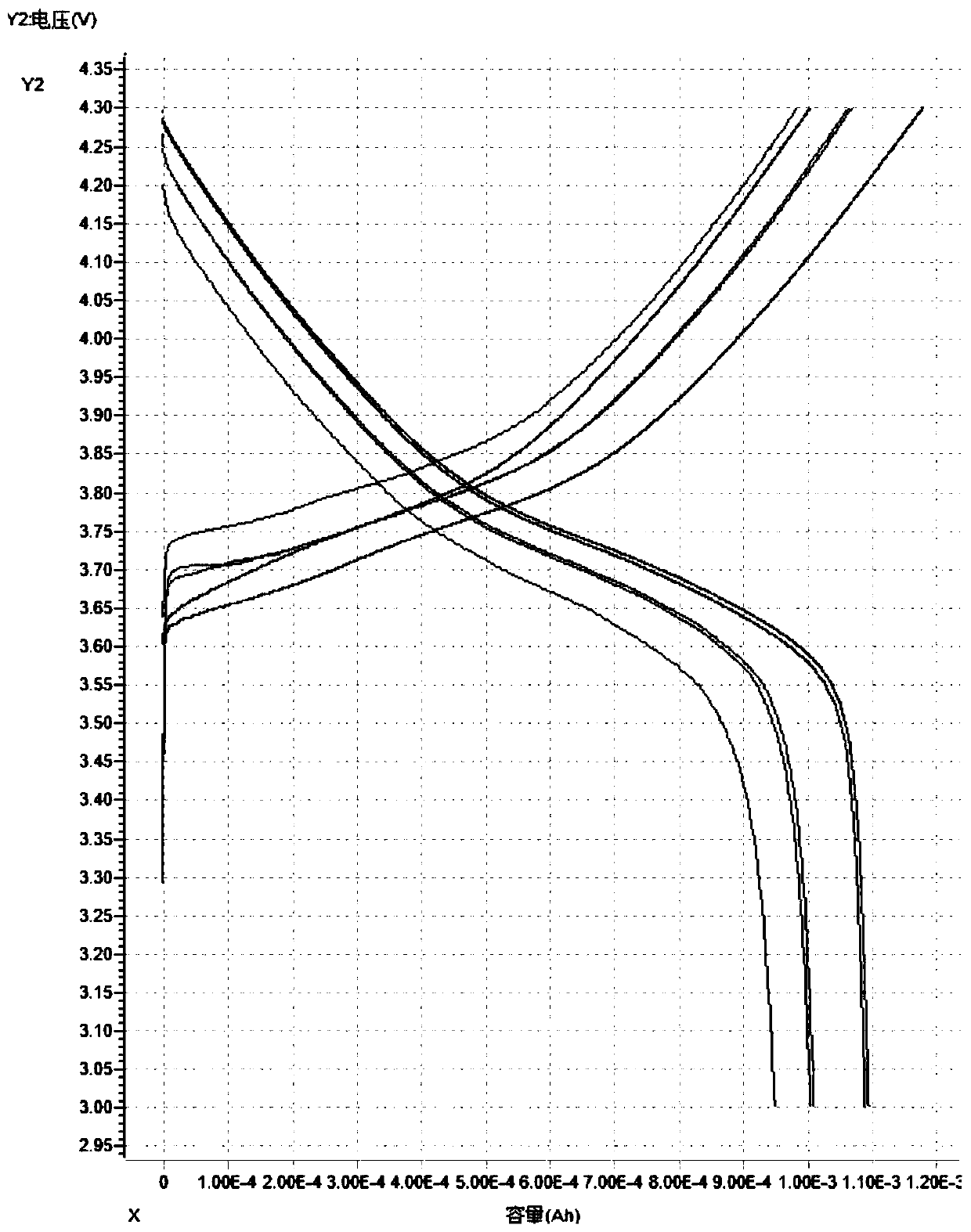

Examples

Embodiment 1

[0041] A method for preparing a nickel-cobalt-manganese ternary positive electrode spherical material, specifically comprising the following steps:

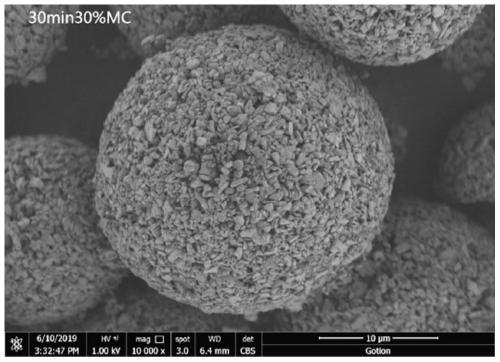

[0042] (1) According to the molar ratio Li:Me=1.03, take 100kg of nickel-cobalt-manganese ternary precursor (Me) and lithium source, and take 1kg of vanadium pentoxide (V 2 o 5 ), 10kg of nano-mesoporous silica, 1kg of glucose and deionized water were put into a mixing tank and mixed for 1 hour to obtain a slurry (solid mass content 35%), and then sanded by a sand mill for 50 minutes. During sanding, the particle size of the slurry was controlled to D50 D100 is 0.5-1.5μm, D100 is 20-50μm; finally carry out centrifugal spray granulation drying to obtain the mixture, the parameters of centrifugal spray granulation drying include inlet temperature 250℃, outlet temperature 100℃, The pump speed is 600L / h, the centrifuge parameters are 20000 rpm, and the particle size of the dried material is controlled to be 0.5-1.5μm for D50 and 20-...

Embodiment 2

[0047] A method for preparing a nickel-cobalt-manganese ternary positive electrode spherical material, specifically comprising the following steps:

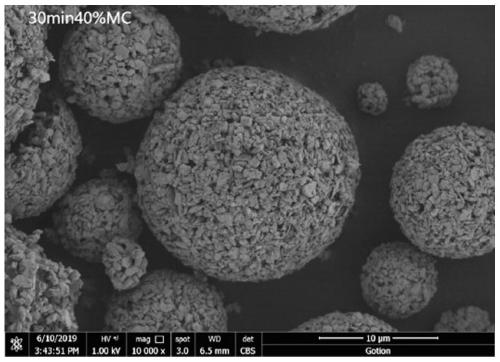

[0048](1) According to the molar ratio Li: Me=1.04, take nickel-cobalt-manganese ternary precursor (Me) and lithium source 100kg, and take 40kgV at the same time 2 o 5 , 30kg of nano-mesoporous silica, 5kg of glucose and deionized water were put into a mixing tank and mixed for 40 minutes to obtain a slurry (solid mass content 40%), and then sanded by a sand mill for 100 minutes, and the particle size D50 of the slurry was controlled during sanding. 0.5-1.5μm, D100 is 20-50μm; finally carry out centrifugal spray granulation drying to obtain the mixture, the parameters of centrifugal spray granulation drying include inlet temperature 300℃, outlet temperature 110℃, slurry pump The speed is 600L / h, the centrifuge parameters are 25000 rpm, and the particle size D50 of the dried material is controlled to be 0.5-1.5μm, and the D100 is...

Embodiment 3

[0053] A method for preparing a nickel-cobalt-manganese ternary positive electrode spherical material, specifically comprising the following steps:

[0054] (1) According to the molar ratio Li:Me=1.08, take nickel-cobalt-manganese ternary precursor (Me) and lithium source 100kg, and take 20kgV at the same time 2 o 5 , 20kg of nano-mesoporous silica, 10kg of glucose and deionized water were put into a mixing tank and mixed for 60 minutes to obtain a slurry (solid mass content 40%), and then sanded by a sand mill for 70 minutes, and the particle size D50 of the slurry was controlled during sanding. 0.5-1.5μm, D100 is 20-50μm; finally carry out centrifugal spray granulation drying to obtain the mixture, the parameters of centrifugal spray granulation drying include inlet temperature 300℃, outlet temperature 110℃, slurry pump The speed is 700L / h, the centrifuge parameters are 25000 rpm, and the particle size D50 of the dried material is controlled to be 0.5-1.5μm, and the D100 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com