Movable cold-pressed brick production device and production system

A production device and mobile technology, which are applied in the field of movable cold-pressed brick production devices and production systems, can solve the problems of long-time consumption of cold-pressed bricks, delay of construction progress, and easy collision of cold-pressed bricks. Achieve the effect of saving transportation time, shortening the construction period, and avoiding damage from falling and collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

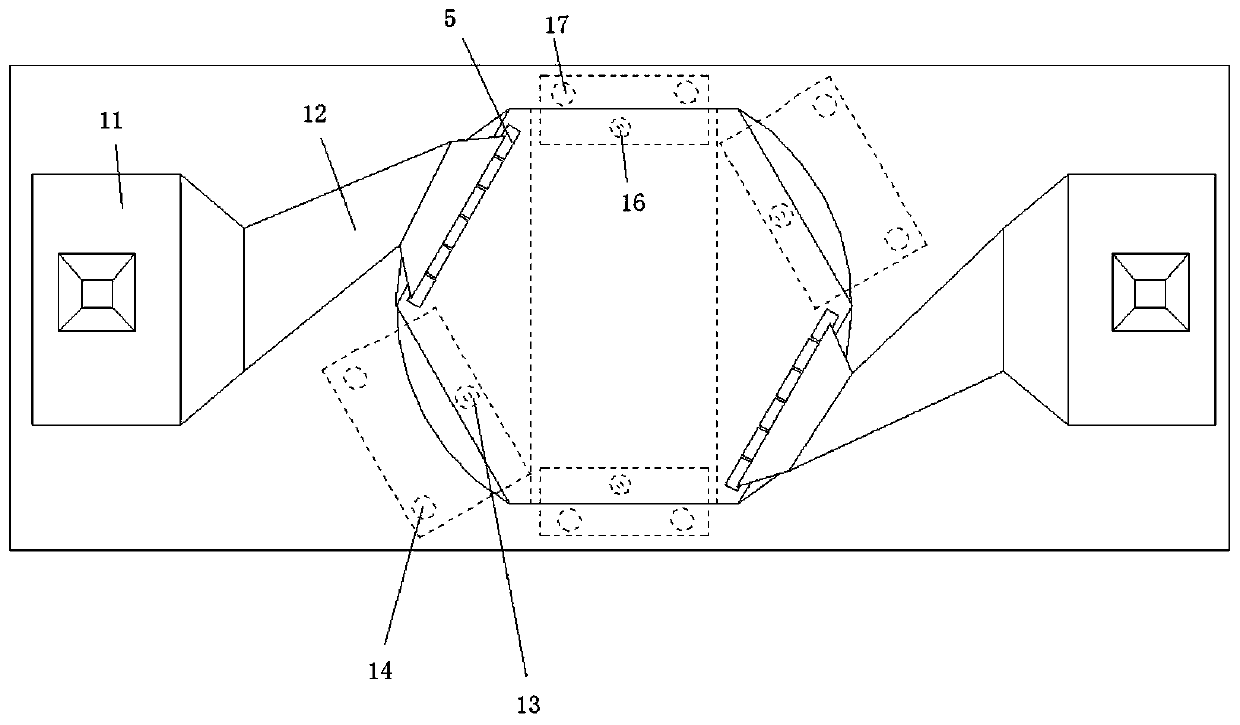

[0061] This embodiment discloses a cold-pressed brick production system, such as Figure 8-10 As shown, it includes the mobile cold-pressed brick production device described in Embodiment 1, and also includes a turnover car and a traction mechanism. The turnover car includes a car body, and the car body is a U-shaped structure, including a first car body part 38 and the second car body part 39 vertically arranged on both sides of the first car body part, the two ends of the first car body part are equipped with second road wheels 40, and the front side of the first car body part is installed with A plurality of support forks 41, the width of the support forks is smaller than the distance between two adjacent backrest bars, the top surface of the first body part is provided with a plurality of vertically arranged rubber tubes 42, the top of the rubber tubes The top beam 43 is fixedly connected, the two ends of the top beam are fixed on the top of the second car body part, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com