Automatic internal-supporting tool clamp for pre-welding assembly of special-shaped component

A technology of special-shaped components and tooling fixtures, which is applied in the field of tooling fixtures, can solve problems such as poor assembly accuracy, low assembly efficiency, and inaccurate centering, and achieve the effect of overcoming centering difficulties, simple structure, and ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

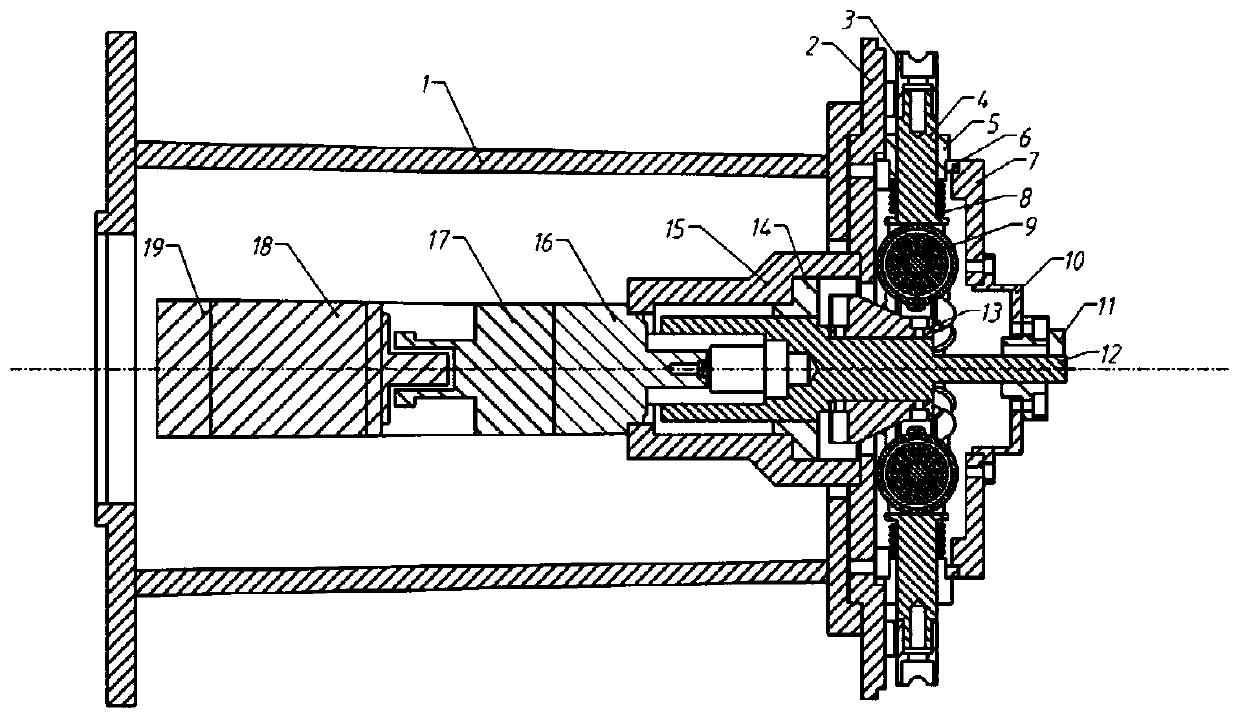

[0026] Specific implementation mode one: combine figure 1 Describe this embodiment, an automatic internal support tooling fixture for pre-welding assembly of special-shaped components in this embodiment, which includes a base module, a motion module, a power module and a control module;

[0027] The base module is composed of a base 1, an end positioning plate 2, an end cover A7, an end cover B10 and a shaft end stopper 11;

[0028] The movement module is composed of a wedge-shaped pad 3, a connecting rod 4, a connecting rod block 5, a casing 6, a return spring 8, a roller 9, an inner support shaft core 12 and a top block 13;

[0029] The power module is composed of a shaft sleeve 14, a positioning sleeve 15, an output screw 16, a reducer 17 and a servo motor 18;

[0030] The control module is made up of the mechanical sensor built in the wedge-shaped pad 3 and the control box 19 positioned at the servo motor rear;

[0031] The base 1 is an I-shaped wheel structure, and the ...

specific Embodiment approach 2

[0036] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and the specific embodiment is: the number of the wedge-shaped pad 3, the connecting rod 4, the connecting rod stopper 5, the return spring 8, the roller 9 and the top block 13 are all 6 . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that the movement range of the wedge-shaped spacer 3 in the radial direction is 0-30 mm.

[0038] Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com