Water temperature constant temperature control method and electric water heating equipment

A control method, electric hot water technology, applied in water boiling appliances, kitchen appliances, household appliances, etc., can solve the problem of inability to accurately control the temperature of hot water, and achieve the effect of reducing the impact of hot water heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a water temperature constant temperature control method, which is mainly used in the field of raising the water temperature, and can be applied to various electrical equipment for heating water such as electric kettles, electric water heaters, and water dispensers.

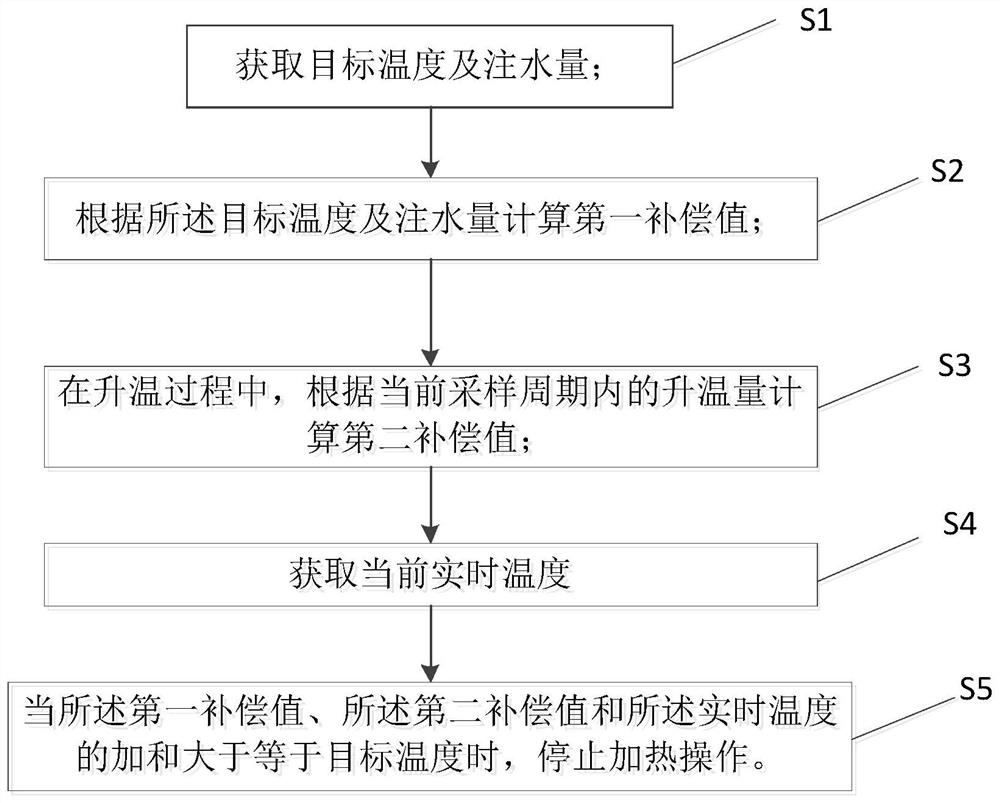

[0027] The control method provided in this embodiment includes the following steps:

[0028] S1. Obtain the target temperature and water injection volume;

[0029] In this step, the target temperature refers to the water temperature of the hot water that the user finally wishes to obtain. According to the different needs of users for hot water, the target temperature will also change accordingly. For example: when brewing green tea, the target temperature is suitable for selection at 80°C-90°C; when brewing Puer tea, the target temperature is suitable for selection 100°C. In this step, the amount of water injected refers to the amount of water injected into the electric kettle by ...

Embodiment 2

[0068] This embodiment provides a computer-readable storage medium, which stores a computer program for execution by an electronic device. When the program runs on the electronic device, the electronic device executes the water temperature constant provided in Embodiment 1. Control Method.

Embodiment 3

[0070] This embodiment provides an electric heating water heating device, including: a temperature acquisition module, used to acquire the real-time temperature in the electric kettle; a water injection volume acquisition module, used to acquire the water injection volume in the electric kettle; a heating module, used for The electric kettle is heated; the temperature compensation module is used to obtain the compensation temperature according to the real-time temperature, the water injection volume and the target temperature; the control module is used to stop when the sum of the compensation temperature and the real-time temperature is greater than or equal to the target temperature Heating operation.

[0071] In the electric heating water heating device provided in this embodiment, the temperature compensation module includes: a first temperature compensation module, which obtains a first temperature compensation value according to the target temperature and the water inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com