Design method of extruded surrounding rock tunnel structure

A technology of tunnel structure and design method, applied in the direction of tunnel, tunnel lining, design optimization/simulation, etc., can solve problems such as complex calculation process, inapplicability, uncertainty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

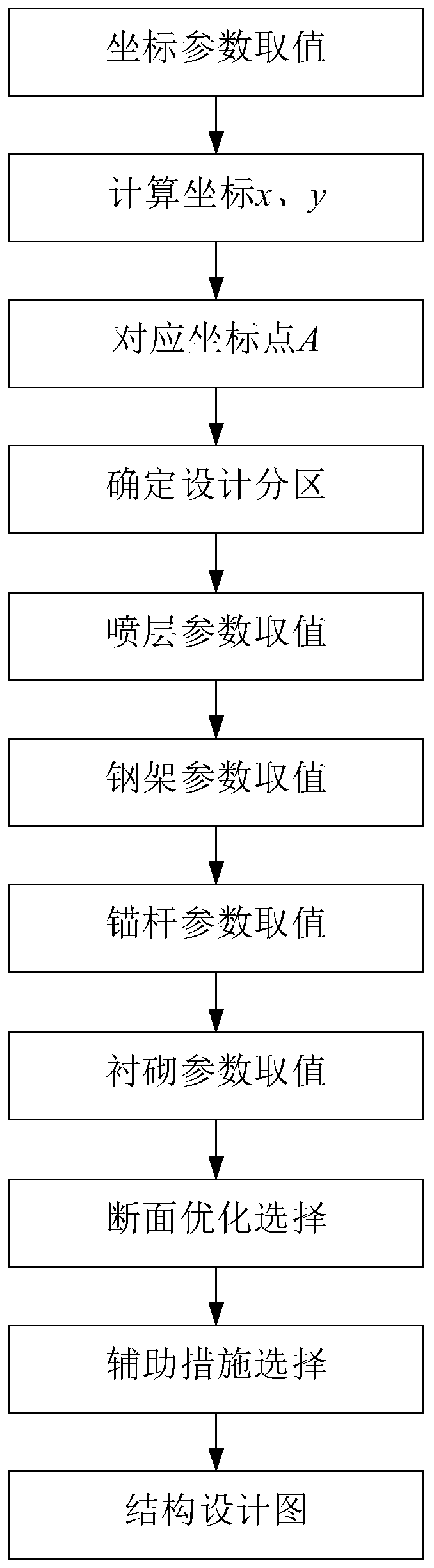

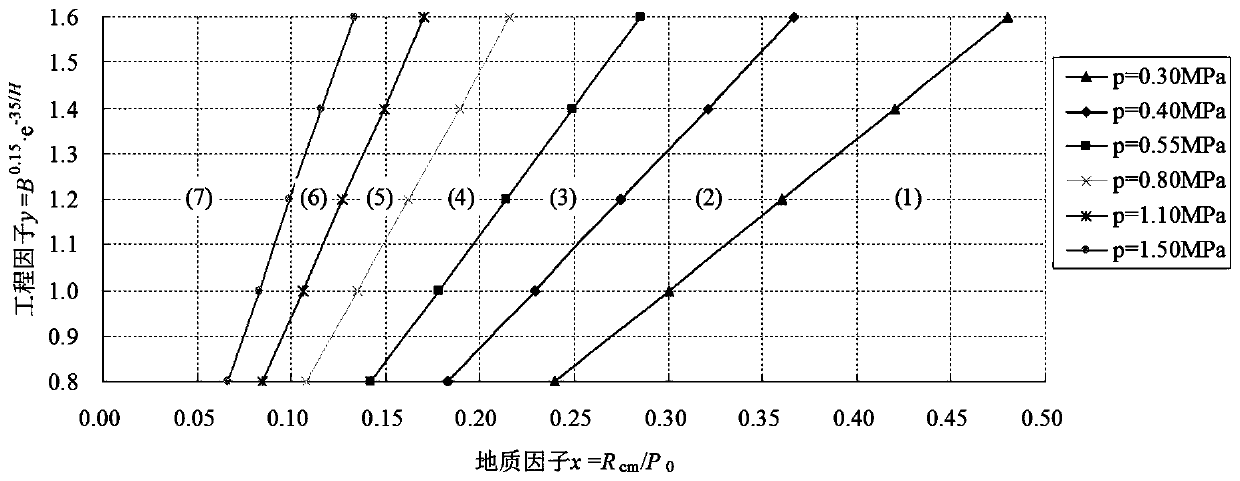

[0136] like Figure 5 As shown in the figure, a tunnel with extruded surrounding rock is a double-track railway tunnel, and the designed excavation span is B t = 14.0m, tunnel burial depth H = 550m, surrounding rock strength stress ratio R cm / P 0 = 0.16 (the predicted deformation level is 2), then x = 0.16, y = 1.394, and A(0.16, 1.394) is obtained, corresponding to Figure 4 In practice, single-layer support is adopted, the thickness of spray layer is 35cm, H175@0.5m, the length of anchor rod is 6.5m, the thickness of secondary lining concrete is 65cm, and measures to optimize the curvature of the section are adopted; through the design method of the present invention, it can be Get the structural design diagram as Figure 5 shown.

[0137] Application inspection of the design method of the present invention:

[0138] The design method of the present invention passes through typical extruded surrounding rocks such as the Wushaoling Tunnel of the Lanxin Line 2, the Guanj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com