A simple filling pile hole depth measuring device and implementation method

A technology of depth measurement and cast-in-place pile, applied in the direction of mechanical depth measurement, etc., can solve the problems of reducing the working efficiency of drilling rigs, deviation of measurement accuracy, mechanical injury accidents, etc., and achieve the effect of ensuring measurement accuracy and construction quality, accurate measurement and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

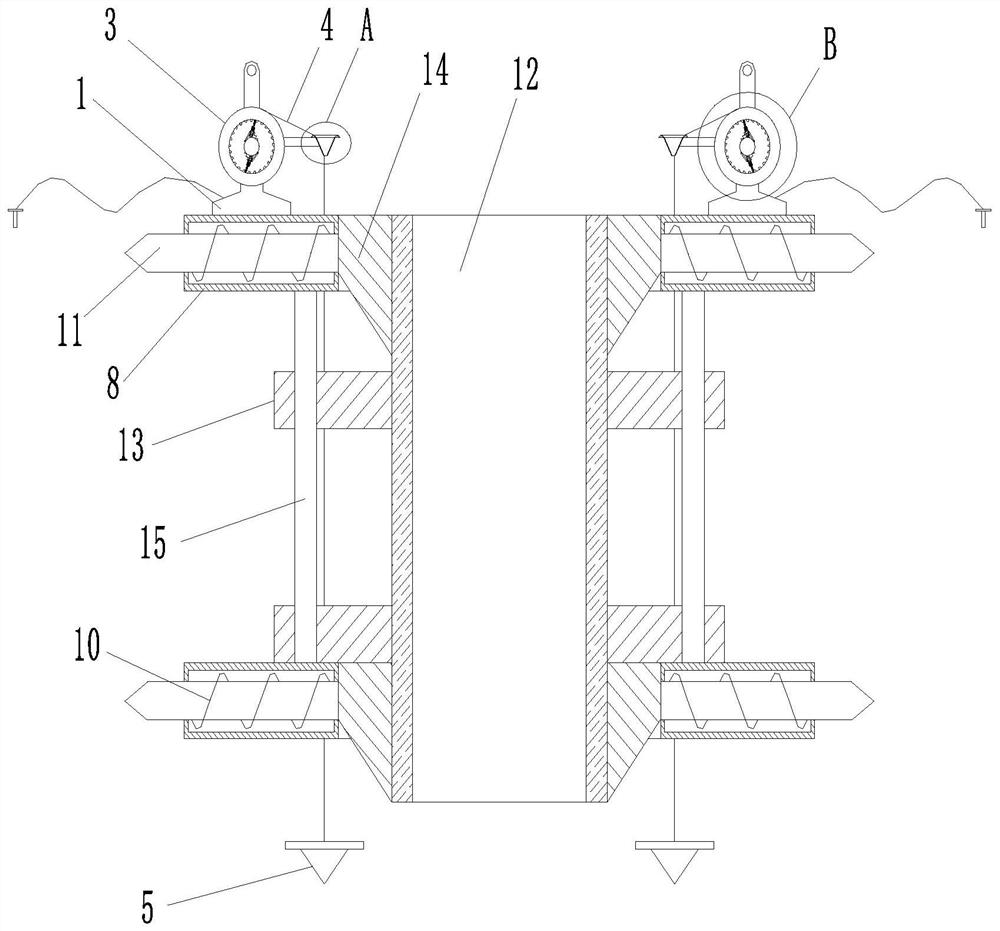

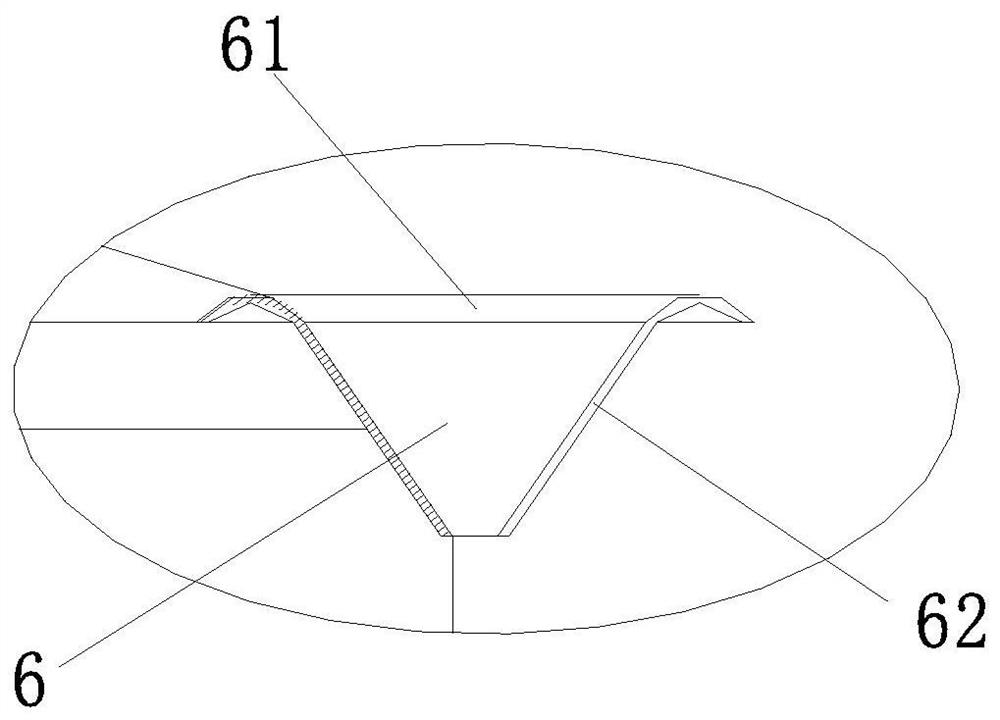

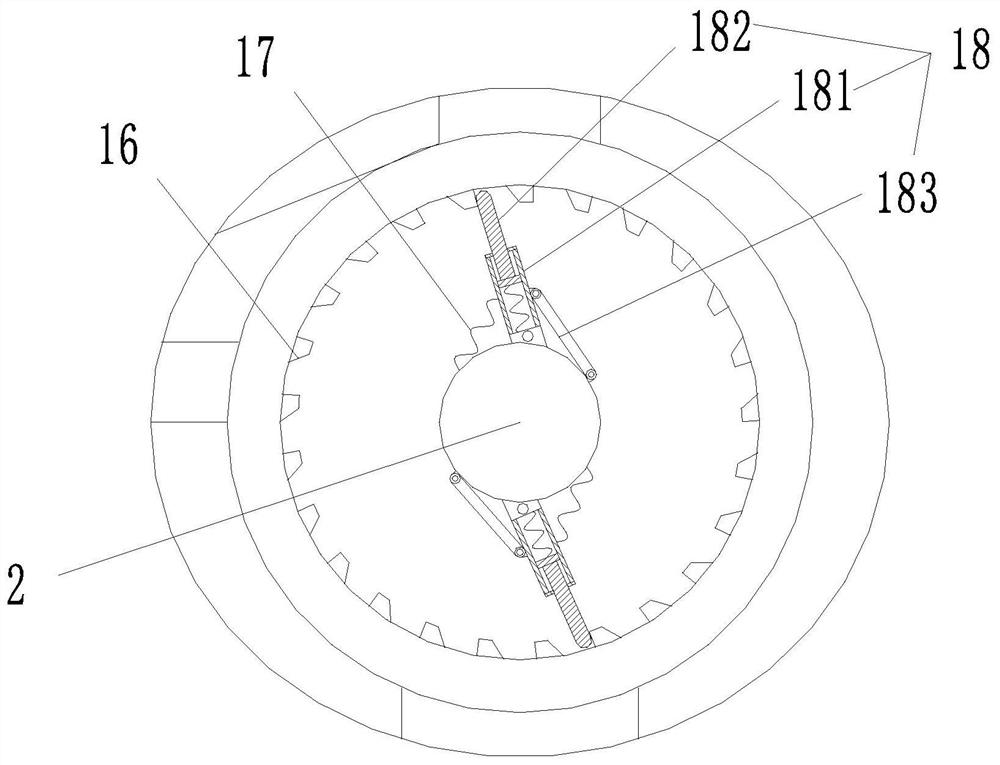

[0031] Such as Figure 1 to Figure 4 As shown, a simple hole depth measurement device for cast-in-place piles includes a positioning system and a measuring system. The positioning system is set inside the hole of the cast-in-place pile. The measuring system includes a fixed frame 1, a rotating shaft 2, a winding wheel 3, and a measuring line with a scale. 4, the wire hammer 5, the fixed frame 1 is fixedly connected on the positioning system and the fixed frame 1 is provided with a guide frame 6 for measuring the fixed point of the line 4 to move up and down, and the reel 3 is connected to the fixed frame 1 by rotating the rotating shaft 2. There is a rocker on the reel 3, and a weighing unit is provided on the reel 3. The measuring wire 4 is wound on the reel 3 and passed through the guide frame 6 to connect with the hammer 5. The weight measuring unit judges whether the hammer 5 is touched. bottom and read the readings on the measuring line 4 to measure the depth of the cast-...

Embodiment 2

[0040] An implementation method of a simple cast-in-place pile hole depth measuring device, the implementation steps comprising:

[0041] S1. Depth measurement device assembly: install the moving part 12 of the assembled structure, the first fixed seat 7 connected with the second fixed seat 8 through the guide column 15, and install it on the outside of the top of the drilling rig head, and install the measuring system on the second On a fixed seat 7 and arranged alternately with the wedge-shaped push block 14;

[0042] S2. The first fixed seat 7, the second fixed seat 8 and the moving part 12 are arranged coaxially with the drilling rig by using the connecting steel rope and the fixed pile, and the horizontal position is limited;

[0043] S3. With the drilling of the drilling rig, the moving part 12, the slider and the wedge-shaped push block 14 move down as a whole, and the positioning rods 11 in the first fixed seat 7 and the second fixed seat 8 are extended to the wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com