Pit furnace and using method thereof

A well-type furnace and flange technology, which is applied to vertical furnaces, furnaces, furnace types, etc., can solve the problems of heavy workload, long maintenance time, and lower tank height, so as to prolong the service life and reduce the workload of modification , The effect of reducing the cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

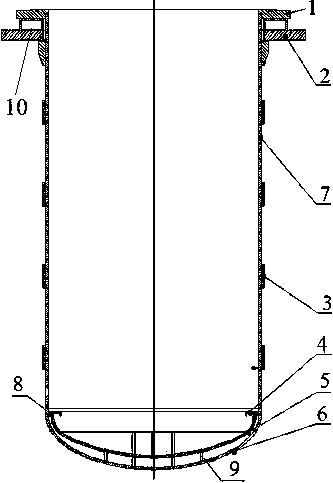

[0031] This embodiment provides a well-type furnace, including a tank body 7 and a tank body head 6, the tank body head 6 is fixed at the bottom of the tank body 7, and the inside of the tank body head 6 is provided with a lining head 5 , a limit device 8 is provided between the liner head 5 and the tank head 6, the liner head 5 is placed in the tank head 6 through a fixing frame 9, and the fixing frame 9 is fixed Inside the tank head 6 , a hoisting structure 4 is uniformly arranged in the circumferential direction of the lining head 5 .

[0032] The liner head 5 is placed inside the tank head 6 to protect the tank head 6. There is a specific limit device 8 between the liner head 5 and the tank head 6 to ensure that the liner Head 5 will not move.

[0033] Principle of the present invention:

[0034] In order to solve the problem that the gas phase structure in the tank body 7 will cause the tank head 6 to be corroded, the bottom of the tank head 6 will be corroded and rotte...

Embodiment 2

[0039] This embodiment provides a well-type furnace, including a tank body 7 and a tank body head 6, the tank body head 6 is fixed at the bottom of the tank body 7, and the inside of the tank body head 6 is provided with a lining head 5 , a limit device 8 is provided between the liner head 5 and the tank head 6, the liner head 5 is placed in the tank head 6 through a fixing frame 9, and the fixing frame 9 is fixed Inside the tank head 6 , a hoisting structure 4 is uniformly arranged in the circumferential direction of the lining head 5 .

[0040] The top of the tank body 7 is fixed with two tank body flanges, which are respectively the upper flange 1 of the tank body and the lower flange 2 of the tank body. The upper flange 1 of the tank body is provided with a sealing ring. A water jacket 10 is provided between the tank flanges.

[0041] The water jacket 10 is arranged between the two tank flanges to prevent the sealing ring from being deformed by heat and affecting the airt...

Embodiment 3

[0043] This embodiment provides a well-type furnace, including a tank body 7 and a tank body head 6, the tank body head 6 is fixed at the bottom of the tank body 7, and the inside of the tank body head 6 is provided with a lining head 5 , a limit device 8 is provided between the liner head 5 and the tank head 6, the liner head 5 is placed in the tank head 6 through a fixing frame 9, and the fixing frame 9 is fixed Inside the tank head 6 , a hoisting structure 4 is uniformly arranged in the circumferential direction of the lining head 5 .

[0044] A plurality of reinforcing ribs 3 are arranged on the outside of the tank body 7 from top to bottom. The distance between two adjacent reinforcing ribs 3 is 200-300mm, the thickness of the reinforcing ribs 3 is 8-10mm, and the width is 0.8-1m.

[0045] In order to ensure the strength of the tank body 7 while reducing the weight of the tank body itself, a plurality of reinforcing ribs 3 are added outside the tank body 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com