Pump body assembly and sliding vane compressor with same

A component and pump body technology, applied in the field of compressors, can solve problems such as loud noise and affect user experience, and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

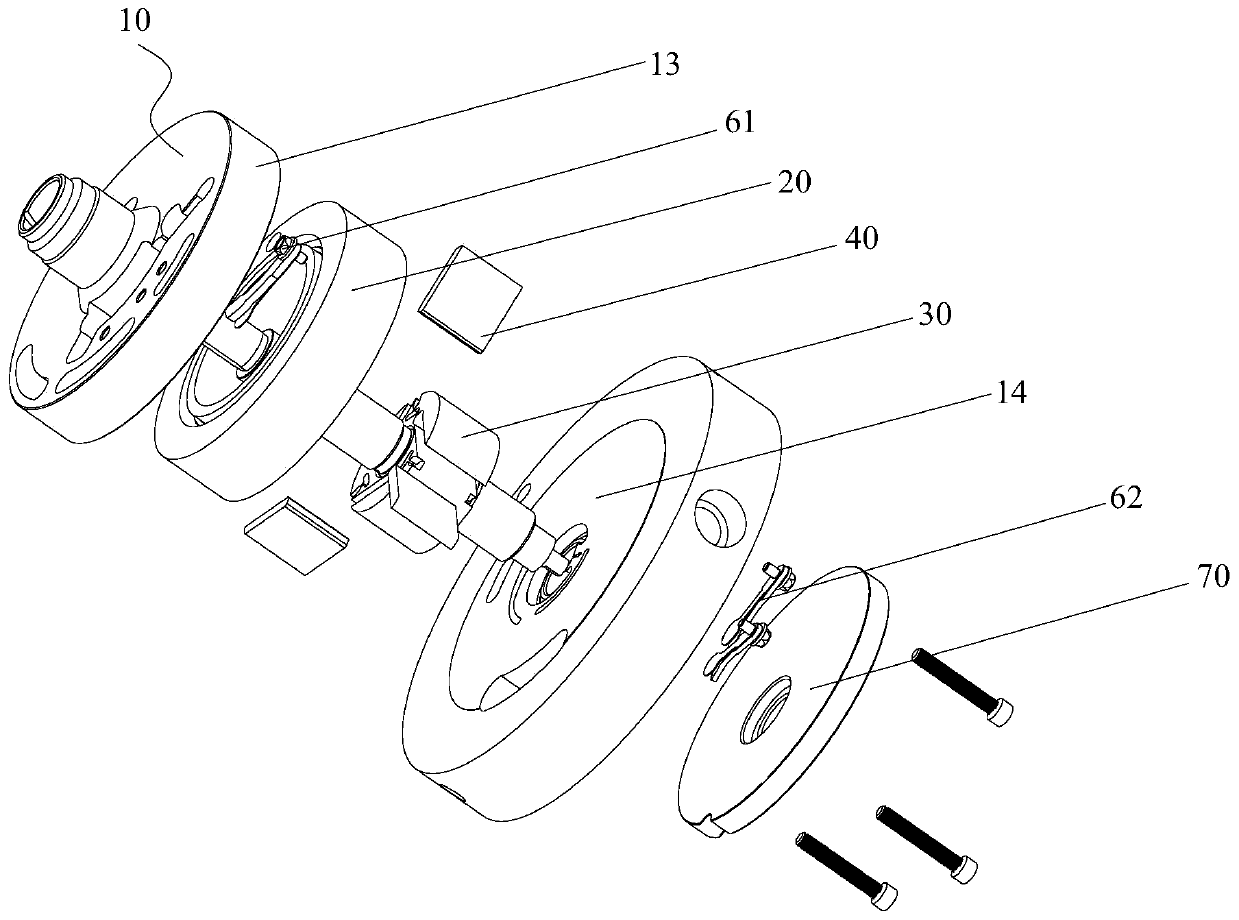

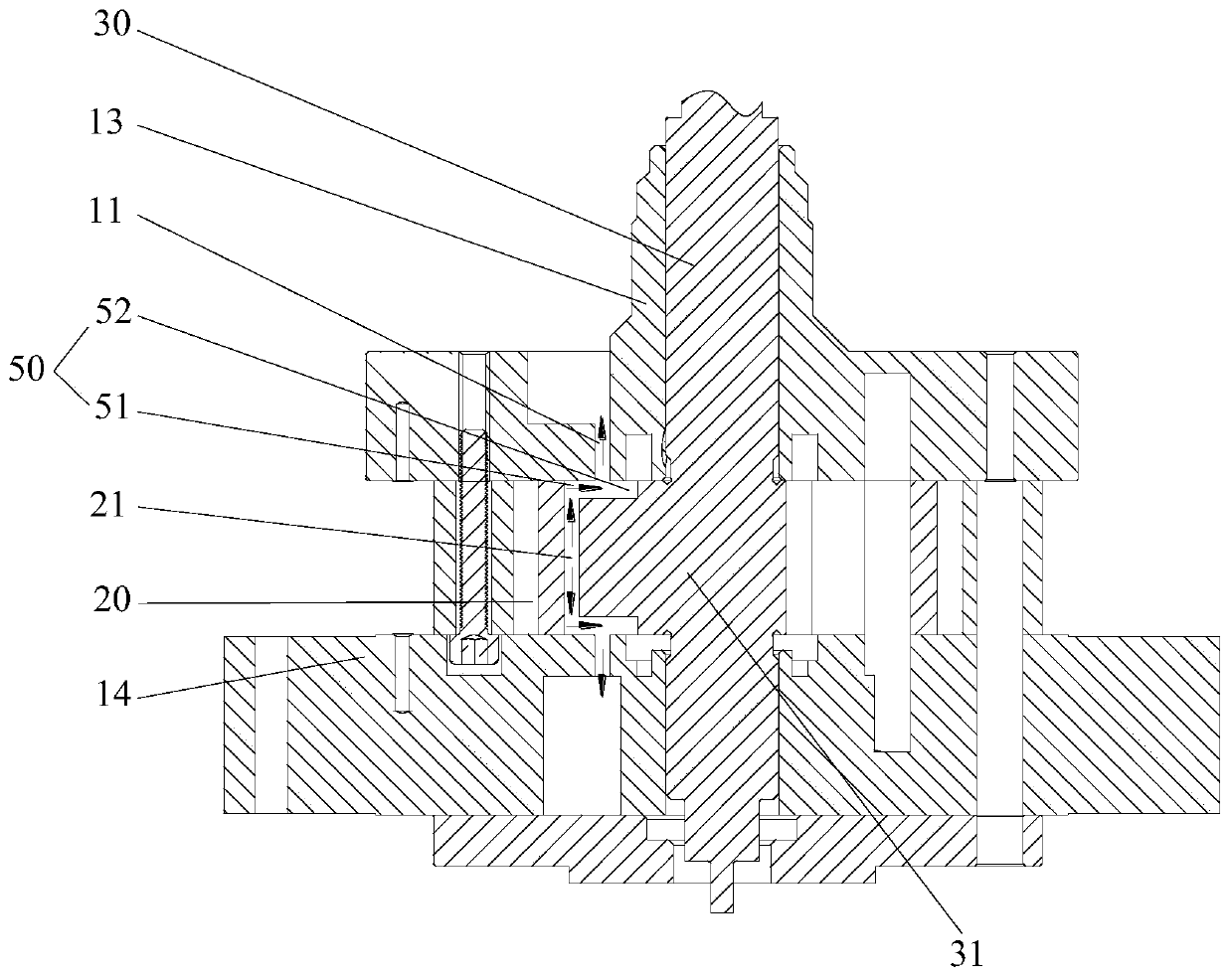

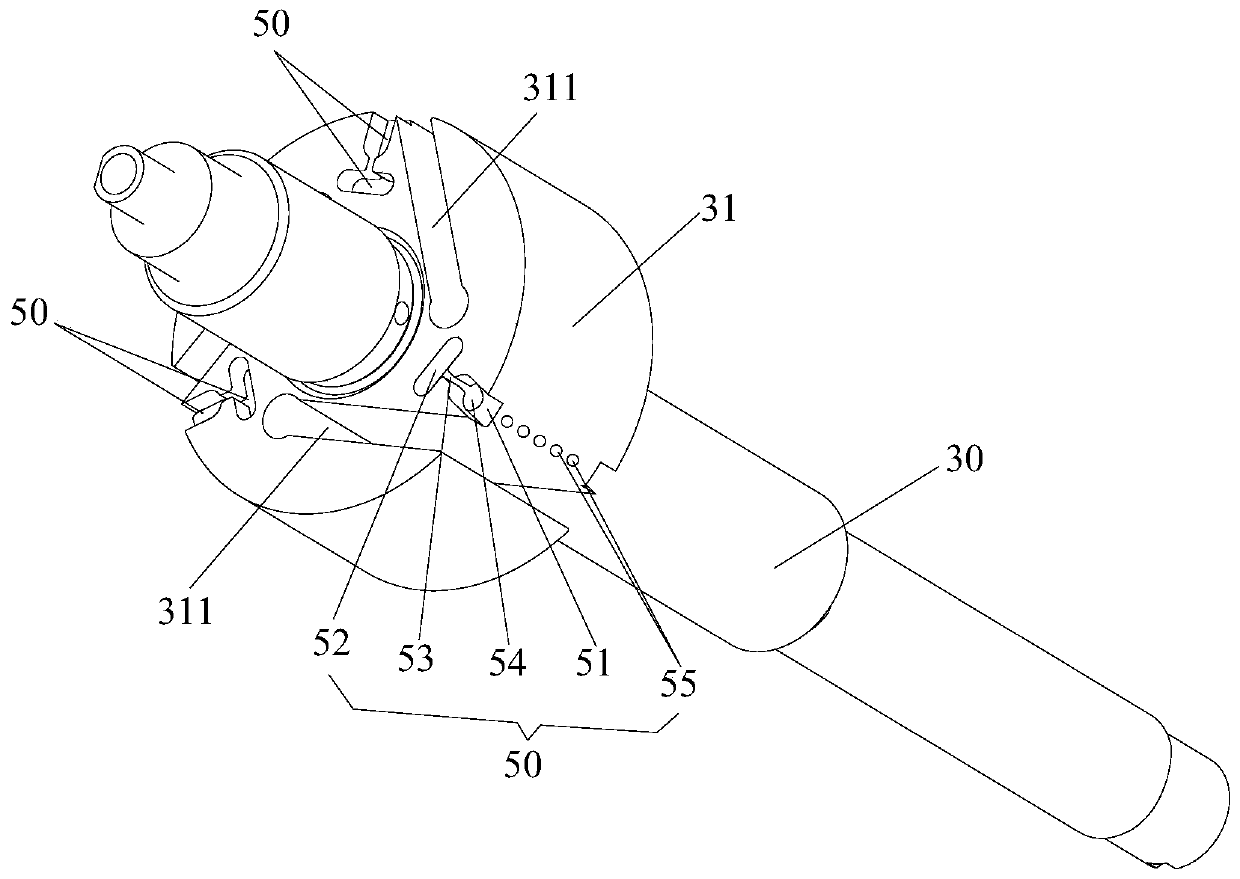

[0037] like figure 1 and figure 2 As shown, the pump body assembly includes a flange 10, a cylinder 20, a rotating shaft 30 and a plurality of sliding vanes 40, the sliding vanes 40 are slidably arranged on the rotor portion 31 of the rotating shaft 30, and the rotor portion 31 is located in the cylinder 20, the pump body assembly An exhaust assembly 50 is also included, and the exhaust assembly 50 is arranged on the rotor part 31 . The exhaust assembly 50 includes a first exhaust structure 51 , a noise reduction structure 52 and a connecting channel 53 . The first exhaust structure 51 extends to the outer peripheral surface of the rotor part 31 . An anechoic chamber is formed between the anechoic structure 52 and the flange 10 . The connection channel 53 communicates with the first exhaust structure 51 , the muffler chamber communicates with the first exhaust structure 51 through the connection channel 53 , and the flange 10 includes an exhaust hole 11 . Wherein, the anec...

Embodiment 2

[0069] The difference between the pump body assembly in the second embodiment and the first embodiment is that the shape of the air inlet hole 55 is different.

[0070] like Figure 8 As shown, the air inlet 55 is a hexagonal structure. The above arrangement makes the processing of the air intake hole 55 easier and simpler, and reduces the processing cost and difficulty of the rotor portion 31 .

Embodiment 3

[0072] The difference between the pump body assembly in the third embodiment and the first embodiment is that the shape of the air inlet hole 55 is different.

[0073] like Figure 9 As shown, the air intake hole 55 is a triangular structure. The above arrangement makes the processing of the air intake hole 55 easier and simpler, and reduces the processing cost and difficulty of the rotor portion 31 .

[0074] From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects:

[0075] The anechoic structure has an anechoic cavity, or an anechoic cavity is formed between the anechoic structure and the flange. The connecting channel communicates with the first exhaust structure, the anechoic cavity communicates with the first exhaust structure through the connecting channel, and the anechoic cavity and the connecting channel form a Helmholtz resonance body. During the operation of the pump bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com