Hydrogen peroxide kerosene variable working condition thrust chamber adopting syringe injector

A technology of hydrogen peroxide and injectors, which is applied in the direction of jet propulsion devices, machines/engines, rocket engine devices, etc., to achieve the effect of simplifying the ignition structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

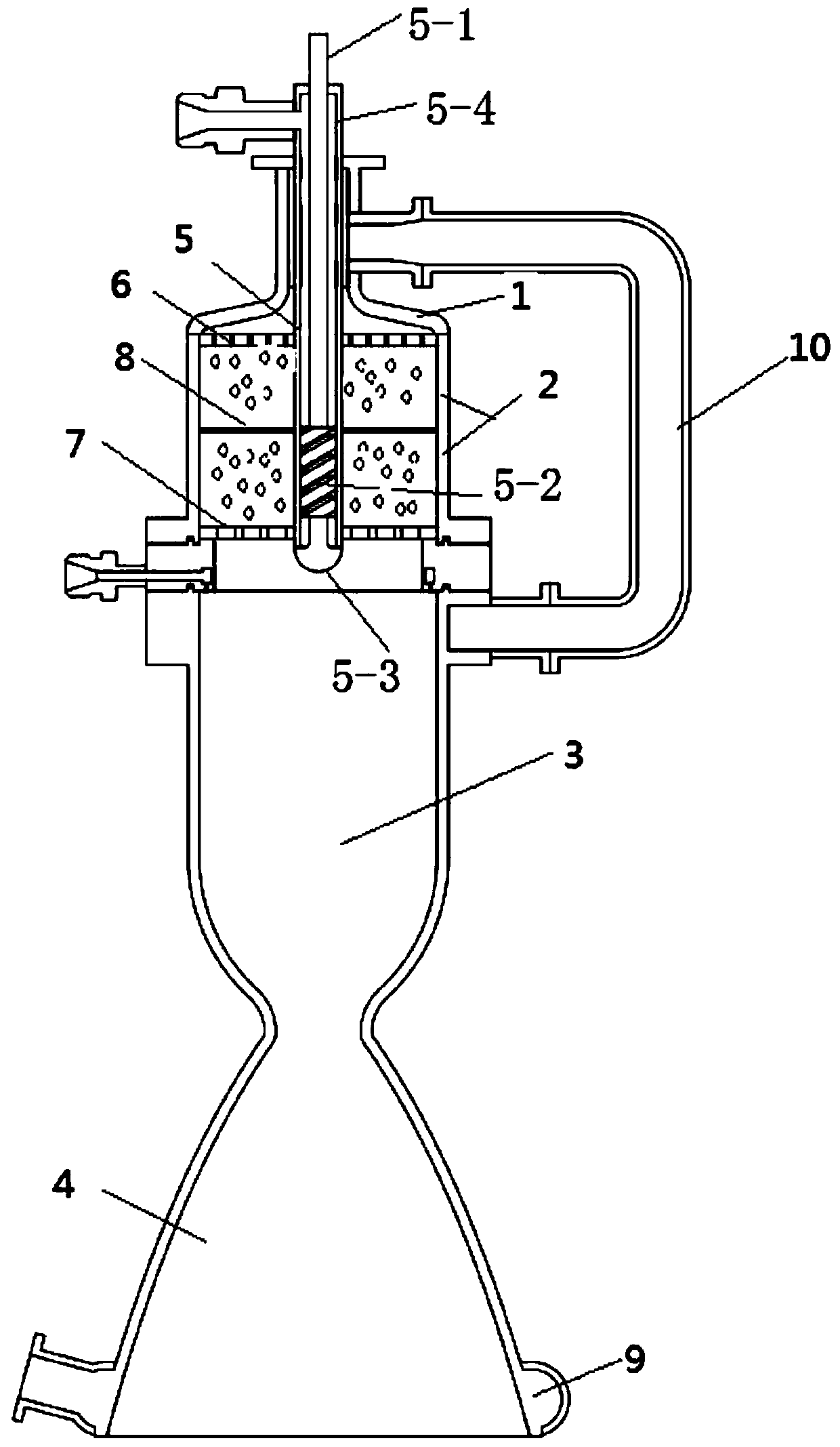

[0019] A kind of hydrogen peroxide kerosene variable working condition thrust chamber adopting pintle injector of the present invention, such as figure 1 As shown, from top to bottom, it includes the injection chamber 1, the catalytic chamber 2 and the combustion chamber 3 connected in sequence, and also includes the injector 5; the injector 5 is axially and coaxially arranged in the injection chamber 1, In the catalytic chamber 2 and the combustion chamber 3, its injection end is located in the combustion chamber 3; its injection end is provided with a kerosene injection port with an adjustable opening size, which is used to inject kerosene fuel towards the combustion chamber 3, and the decomposed process Mixed combustion of hydrogen oxide fuel; an annular hydrogen peroxide channel is formed between the inner wall of the injection chamber 1 and the injector 5; corresponding arrangements are made between the catalytic chamber 2 and the injection chamber 1, and between the catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com