Fermentation device for preparing liquid organic fertilizer

A liquid organic fertilizer and fermentation device technology, which is applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of inconvenient adjustment of fermentation temperature and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

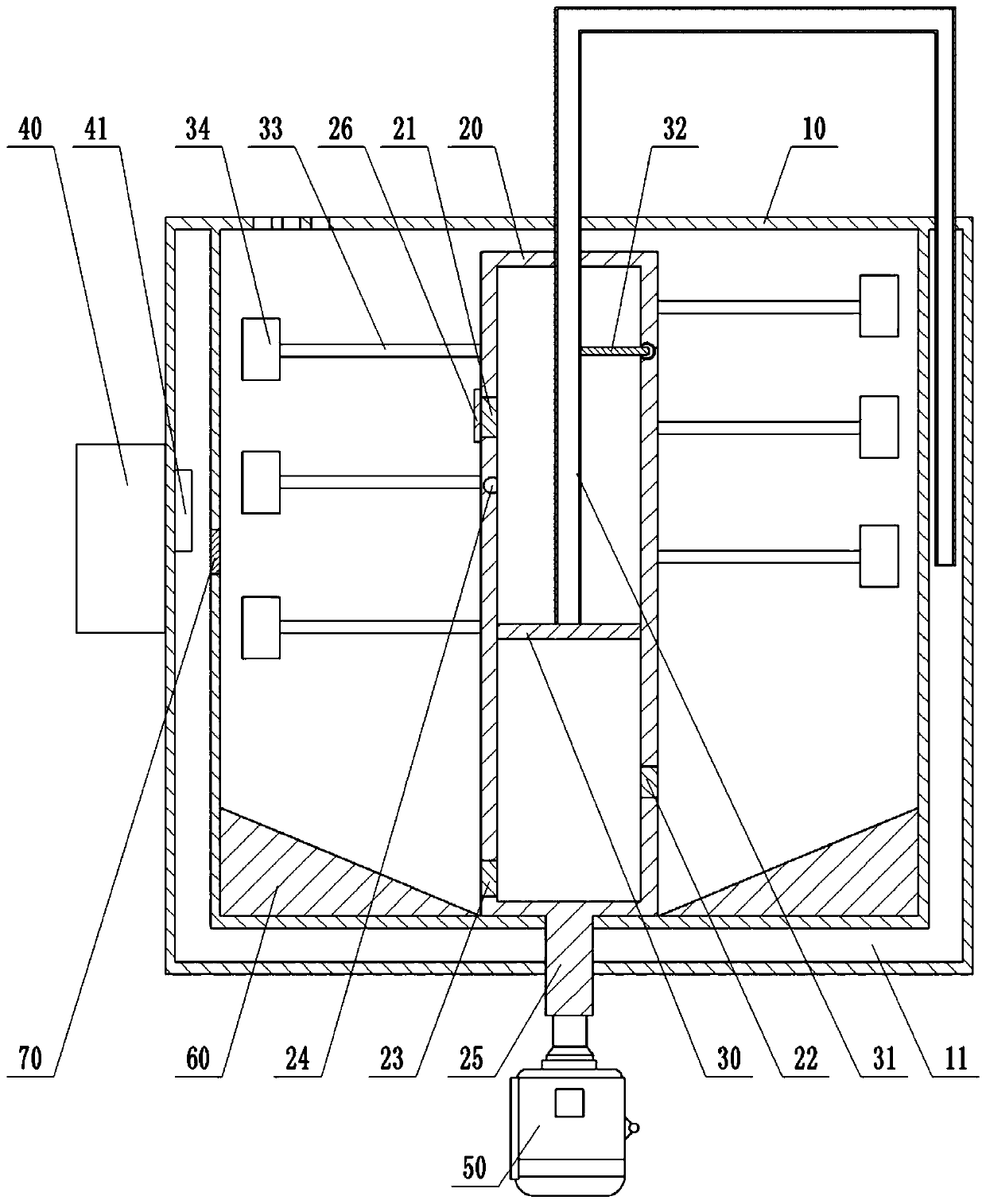

[0026] This embodiment is basically as figure 1 Shown: a fermentation device for preparing liquid organic fertilizer, including a power mechanism, a heating mechanism 40 and a fermentation cylinder 10, and the fermentation cylinder 10 is provided with a plurality of exhaust ports. The heating mechanism 40 includes a sliding rheostat, a switch, an electric heating wire 41, a power supply and a wire, and the wire connects the sliding rheostat, a switch, the electric heating wire 41 and the power supply in series, and the circuit can be connected by closing the switch. In this embodiment, the power supply is a battery, and the sliding rheostat, switch and battery are fixedly installed on the outer wall of the fermentation cylinder 10 through the installation box. A flow cavity 11 is opened in the side wall of the fermentation cylinder 10 , and the electric heating wire 41 is installed in the flow cavity 11 .

[0027]A stirring shaft 20 is rotatably connected to the fermentation ...

Embodiment 2

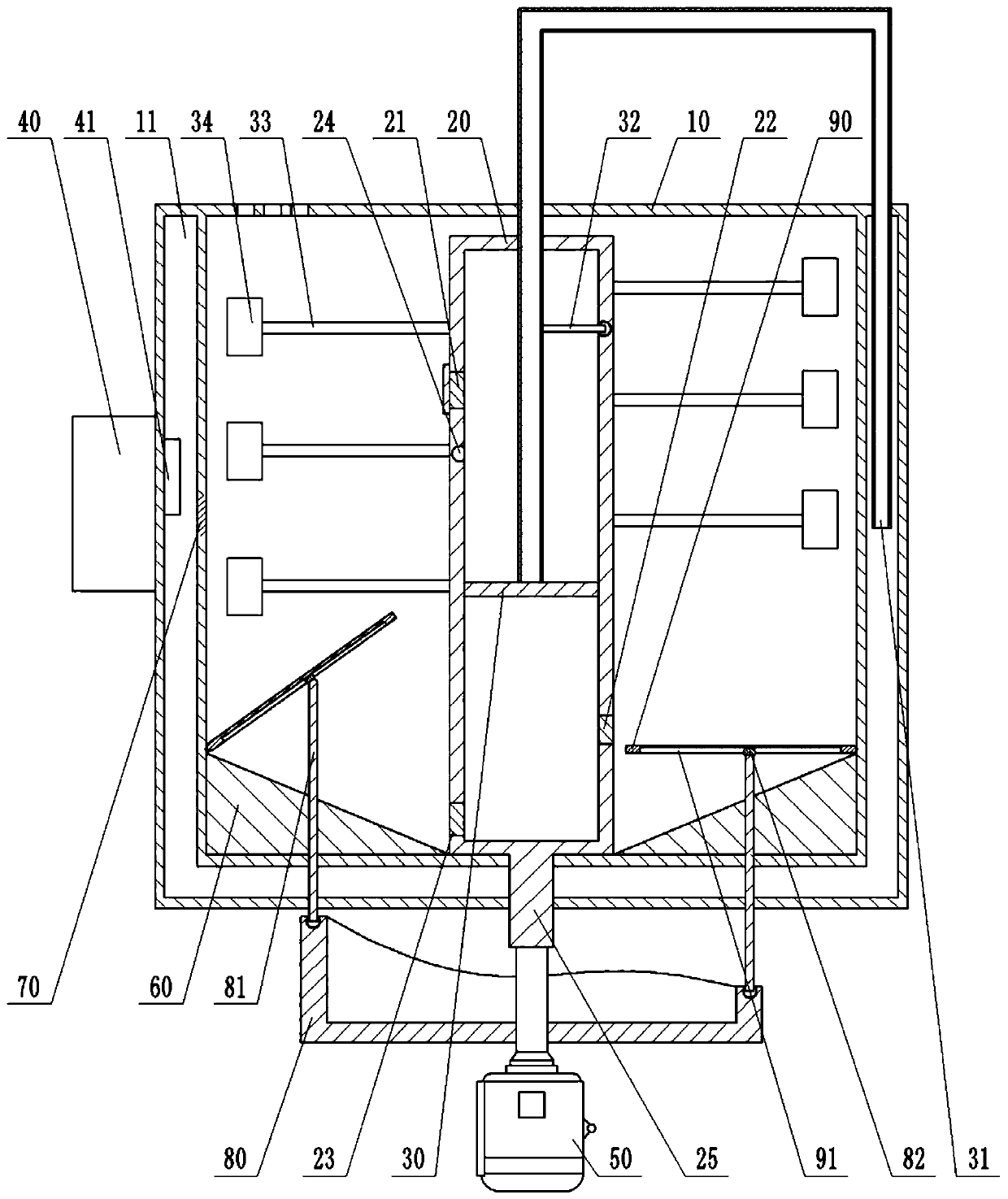

[0031] The difference between this embodiment and Embodiment 1 is that: figure 2 As shown, the inner wall of the fermentation cylinder 10 is hinged with a plurality of turning plates 90 located above the conical drain 60 , and the turning plates 90 are located at the bottom of the fermentation barrel 10 . The bottom of the fermenting cylinder 10 is slidably and sealedly connected with a plurality of ejector pins 81 having the same number as the turnover plates 90 . A cylindrical cam 80 is fixed on the output shaft of the motor 50, and the upper surface of the cylindrical cam 80 has a closed slot, and the lower end of the push rod 81 is rotatably connected with a rolling ball engaged in the slot. A dovetail groove 91 is formed on the lower surface of the turnover plate 90 , and a slider 82 slidingly connected in the dovetail groove 91 is hinged on the upper end of the push rod 81 .

[0032] During the rotation of the cylindrical cam 80, the cylindrical cam 80 drives the eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com