Butt-joint transportation device for photovoltaic production line and butt-joint transportation method

A technology for transportation devices and production lines, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems such as unfavorable and high-efficiency production, labor-saving, and time-wasting problems, so as to improve work efficiency, save manpower, and save handling the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

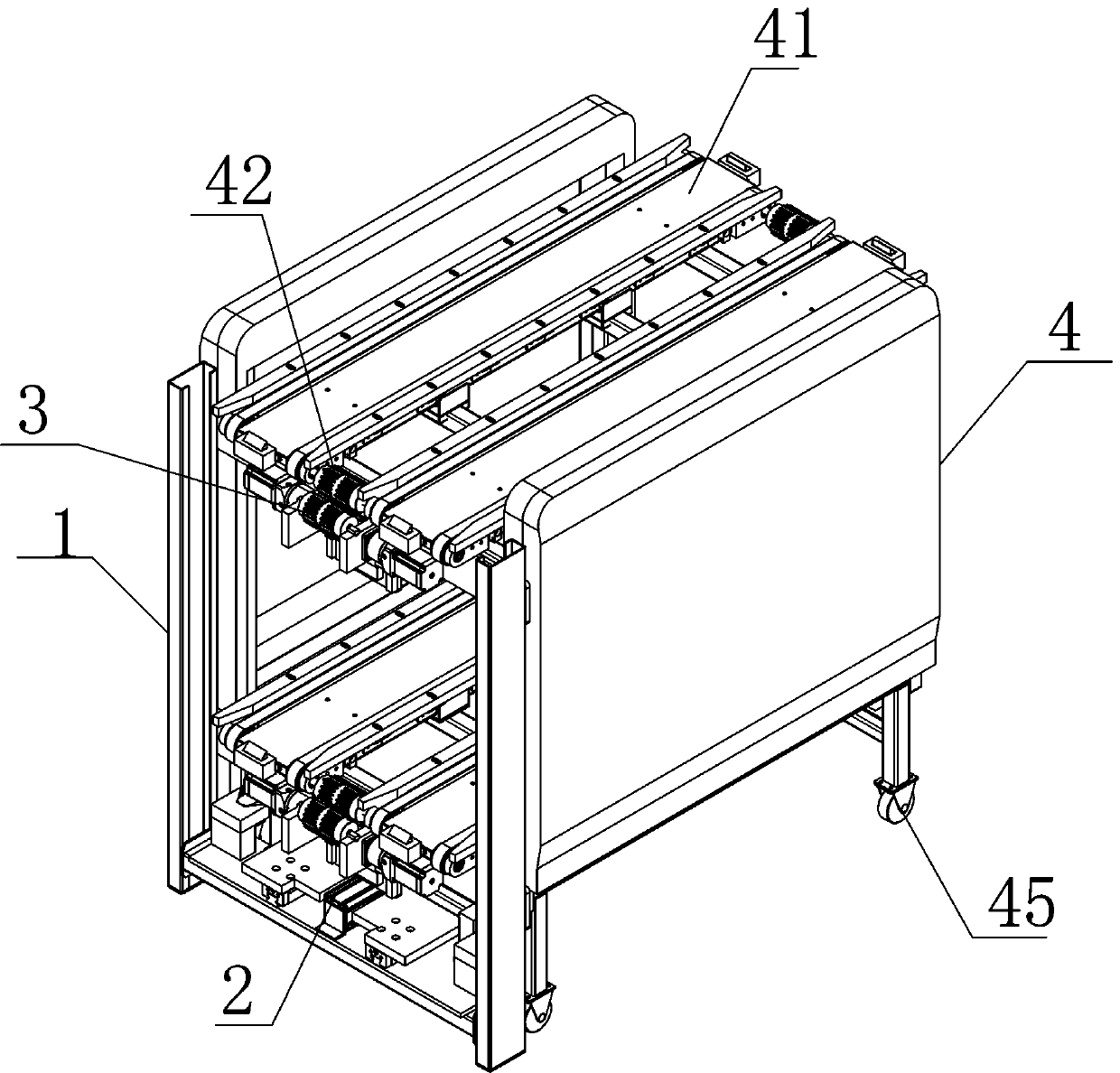

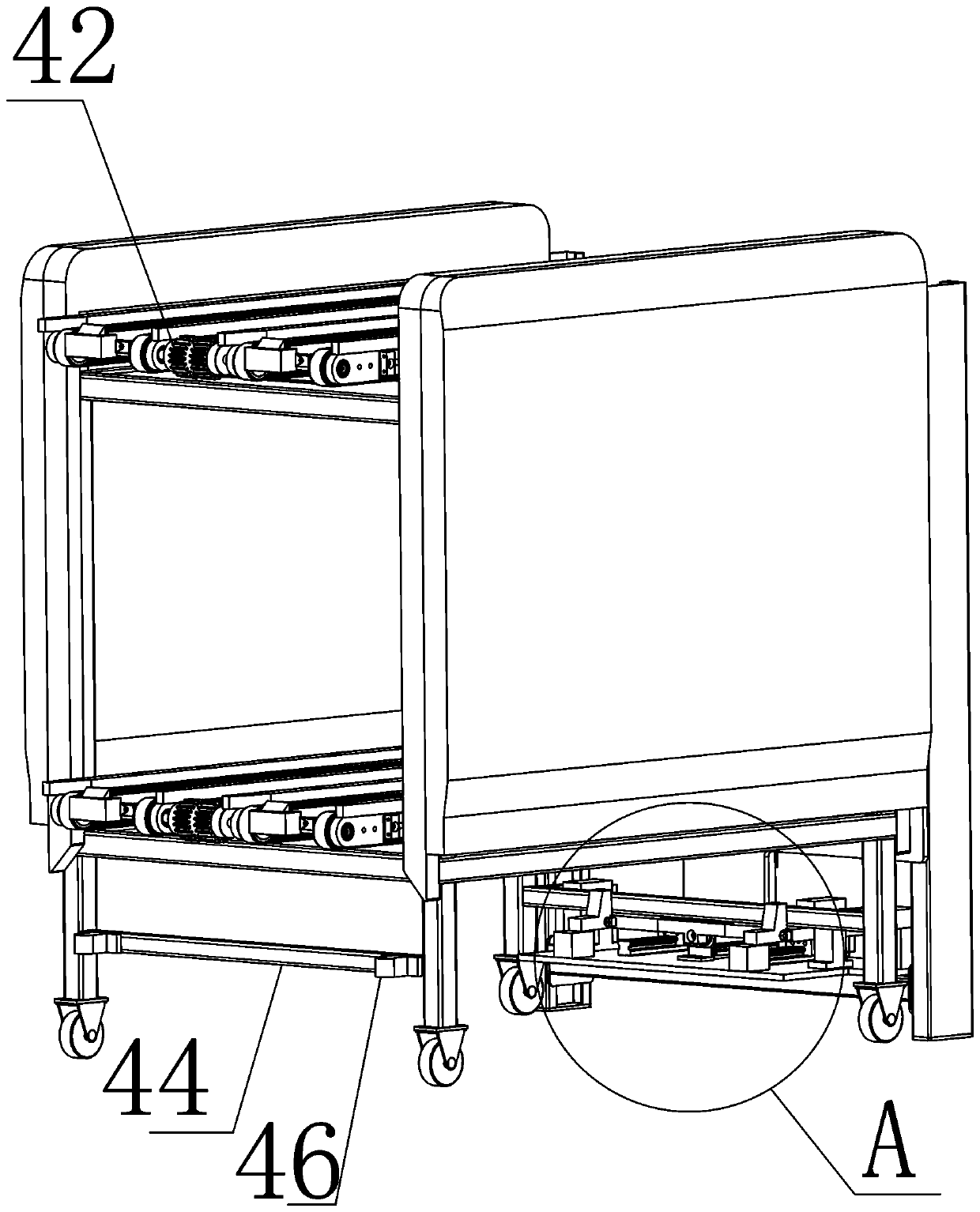

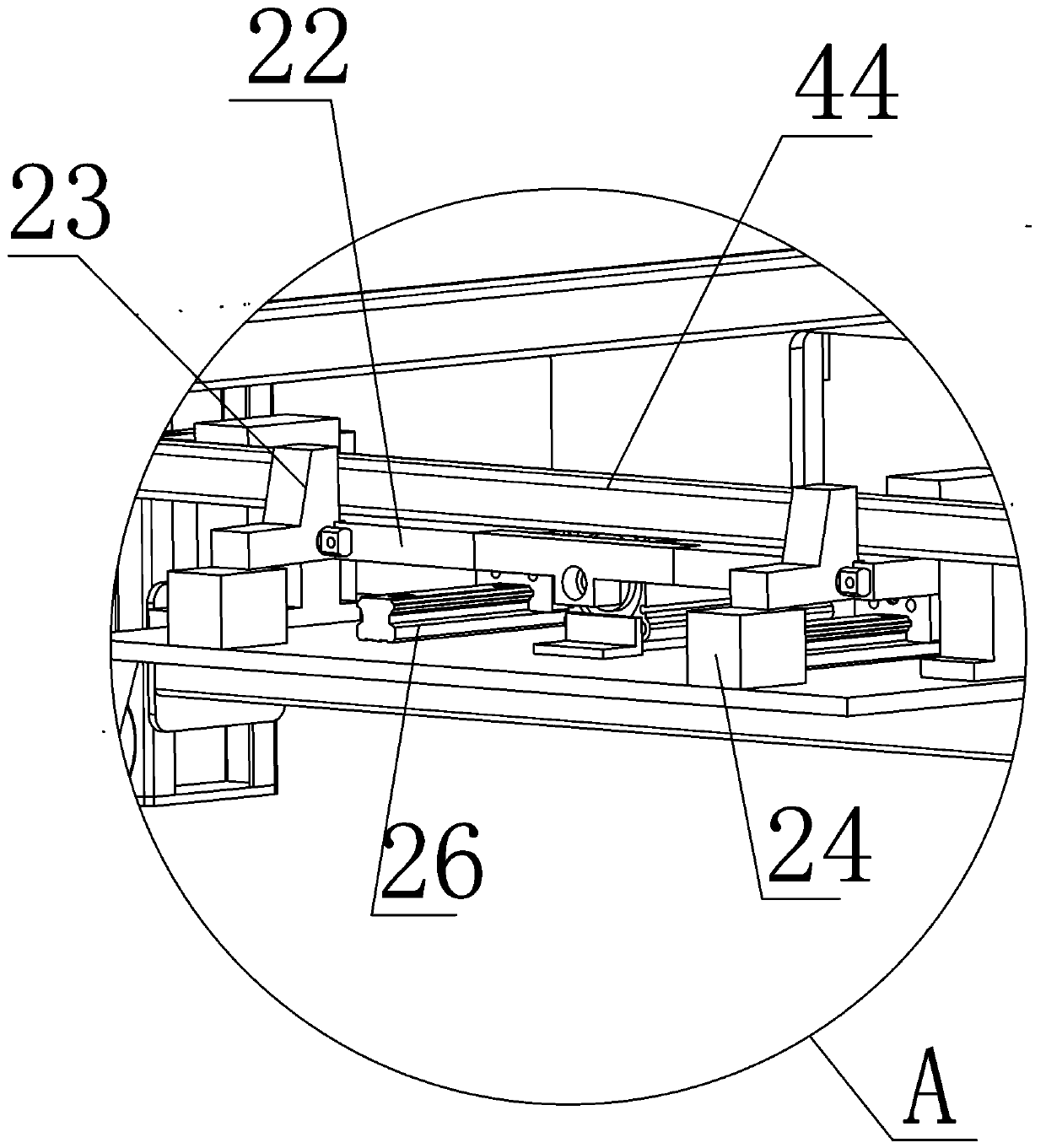

[0031] The preferred solution is Figure 1 to Figure 7 ,as well as Figure 9 to Figure 13 As shown, a docking transportation device for a photovoltaic production line includes a docking machine 1 on which a lock mechanism 2 and a gear drive mechanism 3 are provided, and the lock mechanism 2 is detachably connected to the belt line shelf 4 , The belt line shelf 4 is provided with a conveyor belt 41, which is driven to rotate by a driven gear 42; the gear drive mechanism 3 includes a drive motor 31, which drives the driving gear 32 to rotate, and the driving gear 32 is used with the driven gear 42 meshing.

[0032] Such as Figure 8 with figure 1 As shown, the number of conveyor belts 41 is determined according to the number of belts of the existing belt conveyor 5. Generally, there are four belts of the existing belt conveyor 5, which are arranged in two upper and lower layers. The driven gears 42 are respectively located at the two ends of the conveyor belt 41, so that the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com