Resistance spot welding device and method for unequal thickness plate

A technology of resistance spot welding and thick plates, which is applied in the direction of resistance welding equipment, pressure electrodes, electrode characteristics, etc., can solve problems affecting joint connection strength, weld nugget offset, etc., to improve nugget offset phenomenon, increase The effect of analyzing heat and increasing the current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

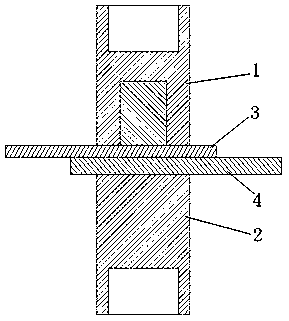

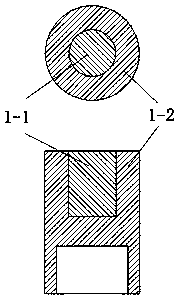

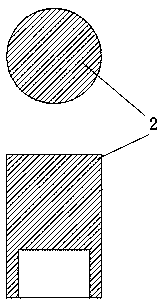

[0034] see Figure 1 to Figure 3 As shown, the resistance spot welding device and method of the unequal thick plate of the present invention comprise small cross-section equal pressure annular cross-section copper electrode, circular cross-section copper electrode, workpiece thin plate and workpiece thick plate; Wherein, small cross-section equal pressure annular cross-section copper The electrode is composed of a copper electrode part and a ceramic part; when welding, use a small cross-section equal-pressure annular cross-section copper electrode on the thin plate side of the workpiece, and use a circular cross-section copper electrode on the thick plate side of the workpiece; by increasing the current density of the thin plate of the workpiece, increase the current density of the thin plate of the workpiece Heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com