Welding strip correcting device for photovoltaic module laminating machine

A photovoltaic module and laminator technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of high use limitations and non-adjustable spacing of the second mounting frame, to ensure accuracy, improve adjustment stability, Improve the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

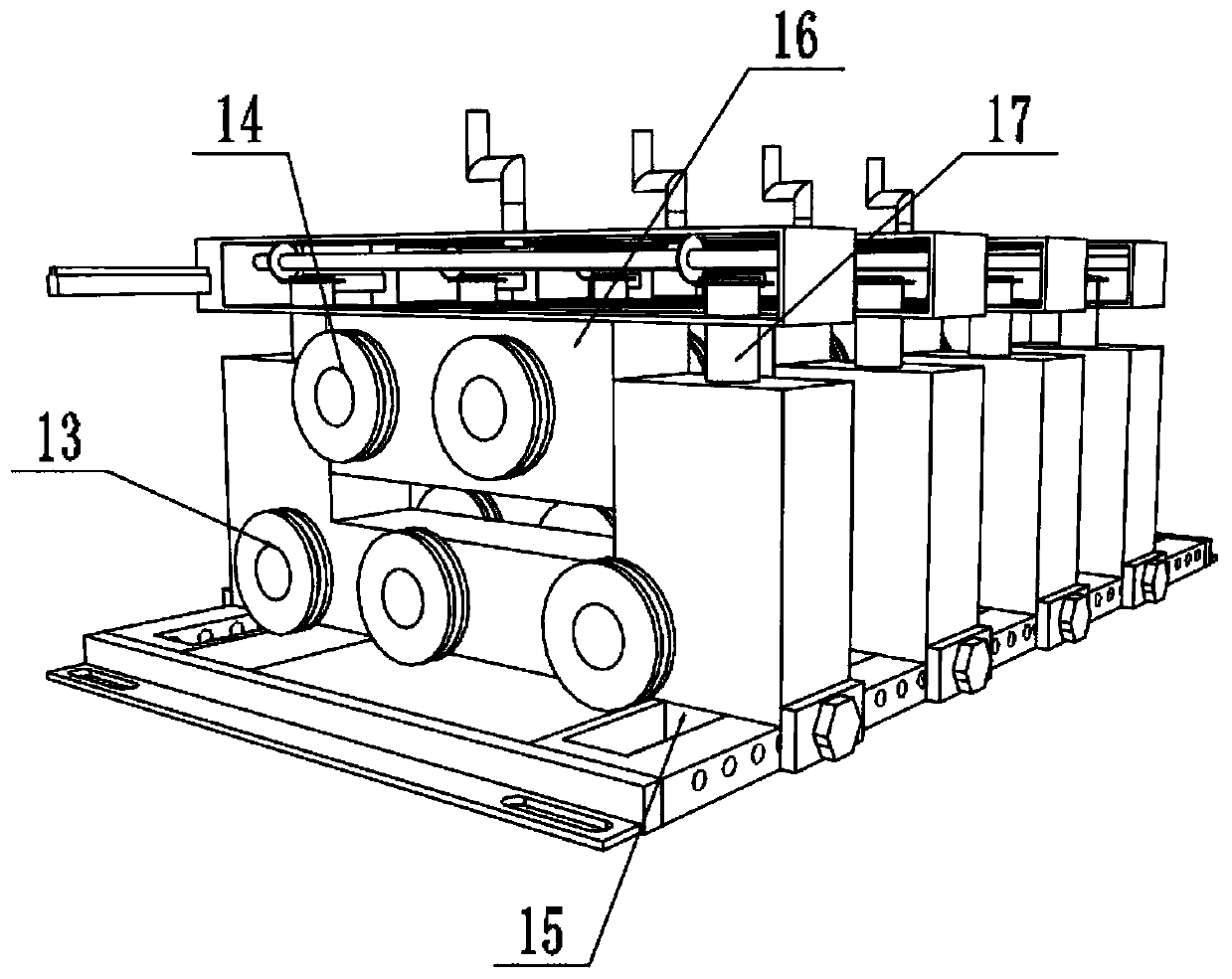

[0027] refer to Figure 1-2 , a welding ribbon correction device for a photovoltaic module laminator, including a connecting frame 1 and a mounting frame 4; a rectangular groove is opened on the top of the mounting frame 4, and a connecting block 16 is slidably connected in the rectangular groove, and one side of the connecting block 16 Several upper roller bodies 14 are fixed on the outer wall through bearings, and several lower roller bodies 13 are fixed on one side of the mounting frame 4 through bearings, and the upper roller bodies 14 and the lower roller bodies 13 are alternately distributed; the top of the connecting block 16 is provided with a lift Assemblies for lifting and lowering the connection block 16, thereby adjusting the distance between the upper roller body 14 and the lower roller body 13 according to the thickness of the welding strip; both sides of the outer wall on one side of the connecting frame 1 are provided with an adjustment frame 3, and the adjustme...

Embodiment 2

[0034] refer to image 3 , a ribbon straightening device for a photovoltaic module laminator, in order to increase the scope of application of the equipment, this embodiment makes the following improvements on the basis of Embodiment 1: the length of the chute 12 is the same as the length of the adjustment frame 3, adjust Both sides of one end of the frame 3 are provided with positioning grooves 18, and both sides of the outer wall of one side of the connecting frame 1 are welded with positioning protrusions, and there are connection fixing holes in the positioning protrusions; the fixed piece 2 can be fixed in the positioning grooves 18; One end of the adjusting frame 3 is fixed with a fixing bar by a screw, so that different numbers of adjusting frames 3 can be installed and fixed through the fixing bar; thus different numbers of mounting frames 4 can be installed as required, which improves the scope of application of the equipment.

[0035] Working principle: According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com